Unlocking the Potential of Best Home CNC Machines in Woodworking with Step by Step Applications

In the realm of woodworking, the advent of the home CNC machine has revolutionized the way hobbyists and professionals alike approach their craft. No longer limited to traditional hand tools, woodworkers now have the opportunity to unlock their creativity and achieve precision with the aid of advanced technology. This blog delves into the incredible potential of the best home CNC machines available on the market, showcasing step-by-step applications that elevate woodworking projects from simple to extraordinary.

By exploring various examples, we aim to demonstrate not only the versatility of these machines but also how they can enhance the woodworking experience, allowing artisans to transform their visions into reality with unparalleled accuracy and efficiency. Whether you're a seasoned craftsman or a newcomer to the world of woodworking, this comprehensive guide will illuminate the path to harnessing this powerful tool in your workshop.

Benefits of After-Sales Service for Home CNC Machines in Woodworking

When investing in home CNC machines for woodworking, after-sales service plays a crucial role in ensuring long-term satisfaction and functionality. According to a recent report by MarketsandMarkets, the global woodworking machinery market is expected to reach USD 16.84 billion by 2025, highlighting the increasing reliance on precision machinery. Users who have access to robust after-sales support experience fewer disruptions, as maintenance and troubleshooting can be addressed swiftly. A study by Technavio indicates that efficient after-sales service can enhance customer retention rates by up to 28%, underscoring the importance of support in this competitive market.

Moreover, having reliable after-sales service not only improves operational efficiency but also minimizes costs associated with machine downtime. Data from a survey conducted by IBISWorld shows that businesses with strong after-sales support reported a 15% reduction in maintenance costs and increased productivity levels. For hobbyists and professionals alike, the assurance of competent technical assistance enhances the value proposition of home CNC machines, allowing users to maximize their woodworking projects with confidence and creativity.

Understanding Maintenance Costs for CNC Machines: Budgeting Tips

When investing in a CNC machine for woodworking, understanding the maintenance costs is essential for effective budgeting. Research indicates that maintenance can account for 10-15% of the total operating costs for CNC machines annually. This includes routine checks, necessary repairs, and the replacement of critical components like bearings and belts. By setting aside a dedicated maintenance budget, operators can ensure their machines run smoothly and efficiently over time, minimizing costly downtime.

Furthermore, considerations such as the type of machine, its usage frequency, and the materials processed can significantly influence maintenance expenses. For example, a machine frequently used for complex projects may require more regular servicing and part replacements. According to industry reports, CNC systems that implement preventive maintenance can reduce overall repair costs by up to 25%, highlighting the importance of proactive measures. In this context, understanding these financial implications not only helps in choosing the right CNC machine but also optimizes long-term investment returns.

Unlocking the Potential of Best Home CNC Machines in Woodworking with Step by Step Applications - Understanding Maintenance Costs for CNC Machines: Budgeting Tips

| CNC Machine Type | Initial Cost ($) | Average Maintenance Cost/Year ($) | Common Applications | Estimated Lifespan (Years) |

|---|---|---|---|---|

| Entry-Level CNC Router | 800 | 100 | Sign Making, Hobby Projects | 5 |

| Mid-Range CNC Router | 2500 | 250 | Furniture, Cabinetry | 8 |

| High-End CNC Mill | 8000 | 500 | Professional Woodworking, Prototyping | 15 |

| Portable CNC Router | 1500 | 150 | Small Projects, On-Site Work | 7 |

Step-by-Step Guide to Setting Up Your Home CNC Machine for Woodworking

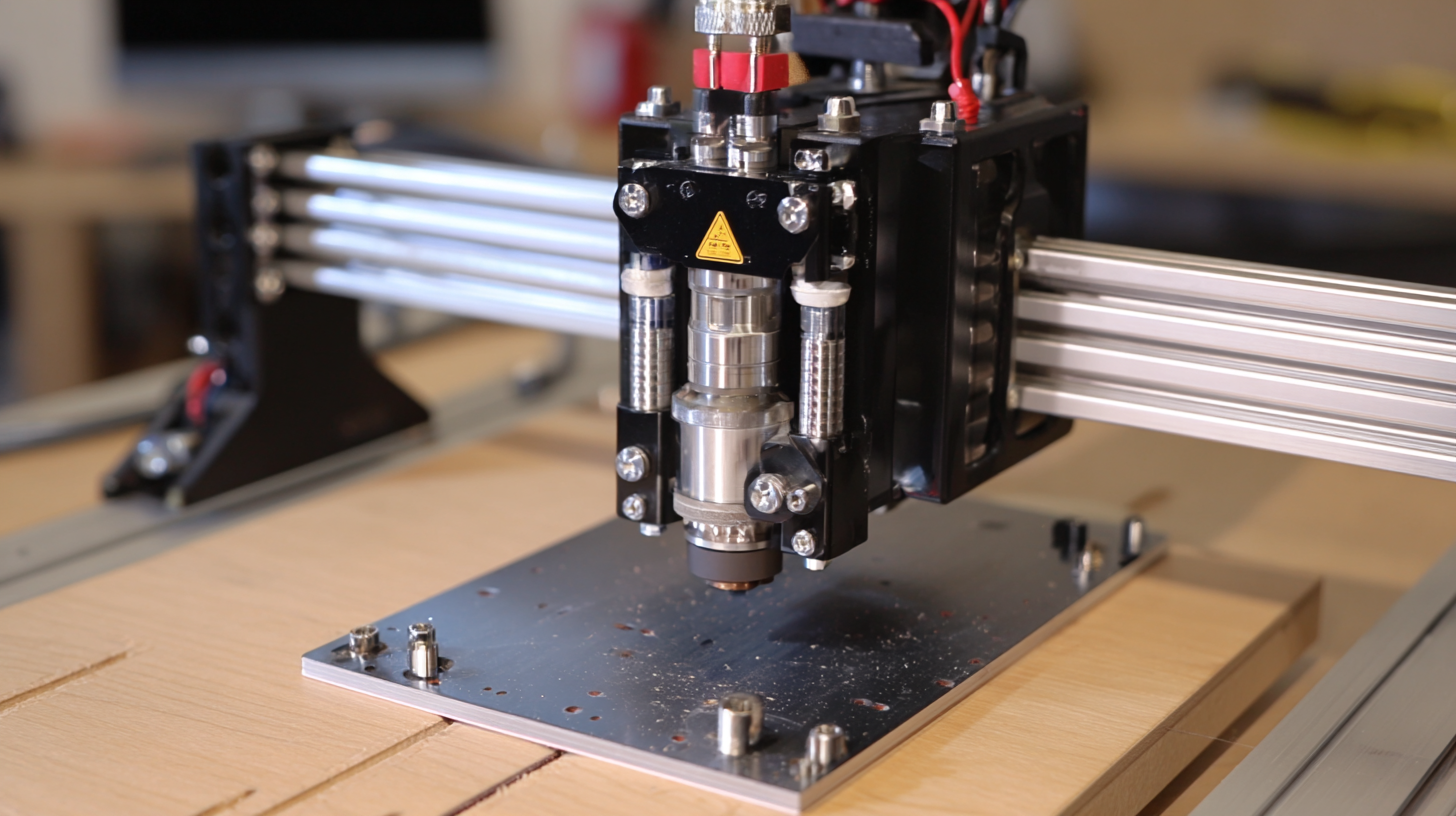

Setting up a home CNC machine for woodworking can seem daunting, but with the right approach, it can be a rewarding venture. According to a report by Technavio, the woodworking CNC machine market is expected to grow by 10% between 2021 and 2025, indicating a rising interest in automated woodworking solutions. To begin your setup, ensure you have a designated space that is well-ventilated and equipped with the necessary power supply. Familiarize yourself with the machine's components—such as the control software, cutting tools, and the work bed—by referring to the user manual and watching instructional videos.

Once your workspace is established, the next step is to calibrate your machine. Proper calibration ensures precision, which is crucial for high-quality wood projects. Industry standards recommend checking the alignment of your axes and the flatness of the work surface. Once the machine is calibrated, you can begin designing your projects using CAD software. A survey by IBISWorld highlights that nearly 50% of woodworking businesses are investing in CNC technology to enhance productivity. This trend underlines the importance of skillful operation and knowing how to leverage CNC capabilities to create intricate designs efficiently.

Common Issues with CNC Machines and How to Repair Them

When working with CNC machines in woodworking, encountering issues is a common experience. Whether it's a misalignment, inaccurate cuts, or software glitches, these problems can disrupt your projects. One effective strategy to tackle these issues involves understanding the root cause—often, it can be traced back to machine setup or tool wear. Regularly inspect your CNC machine for signs of wear and ensure proper tool calibration. This not only helps in identifying potential issues early on but also enhances the overall efficiency of your production runs.

Another crucial aspect is adopting predictive maintenance practices. Leveraging IoT technologies, you can monitor machine performance in real-time and predict when maintenance is needed before problems escalate. For instance, employing artificial intelligence to analyze spindle health can minimize downtime and improve the longevity of your equipment. By addressing common issues proactively and employing data-driven strategies, you can significantly enhance productivity and achieve better results in your woodworking endeavors.

Maximizing Efficiency: Best Practices for Using CNC Machines in Wood Projects

CNC machines are revolutionizing the woodworking industry, offering unparalleled precision and efficiency for wood projects. By integrating CNC technology into your woodworking routine, you can maximize productivity and achieve intricate designs that handwork often cannot match. As we look ahead to 2025, the focus on sustainable forestry practices alongside advanced machinery will play a crucial role in shaping global trade and production. Utilizing best practices when operating CNC machines is essential to leverage their full potential, including proper setup, tool selection, and software optimization.

Emphasizing efficiency during the machining process not only enhances output but also reduces waste, aligning with the industry's shift towards sustainability. As innovations in wood processing machinery emerge, it's vital for woodworkers to stay informed and adopt new technologies that support environmentally friendly practices. Implementing step-by-step applications and techniques will lead to better results and foster a more responsible approach to woodworking, ultimately contributing to a greener future for the industry.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.