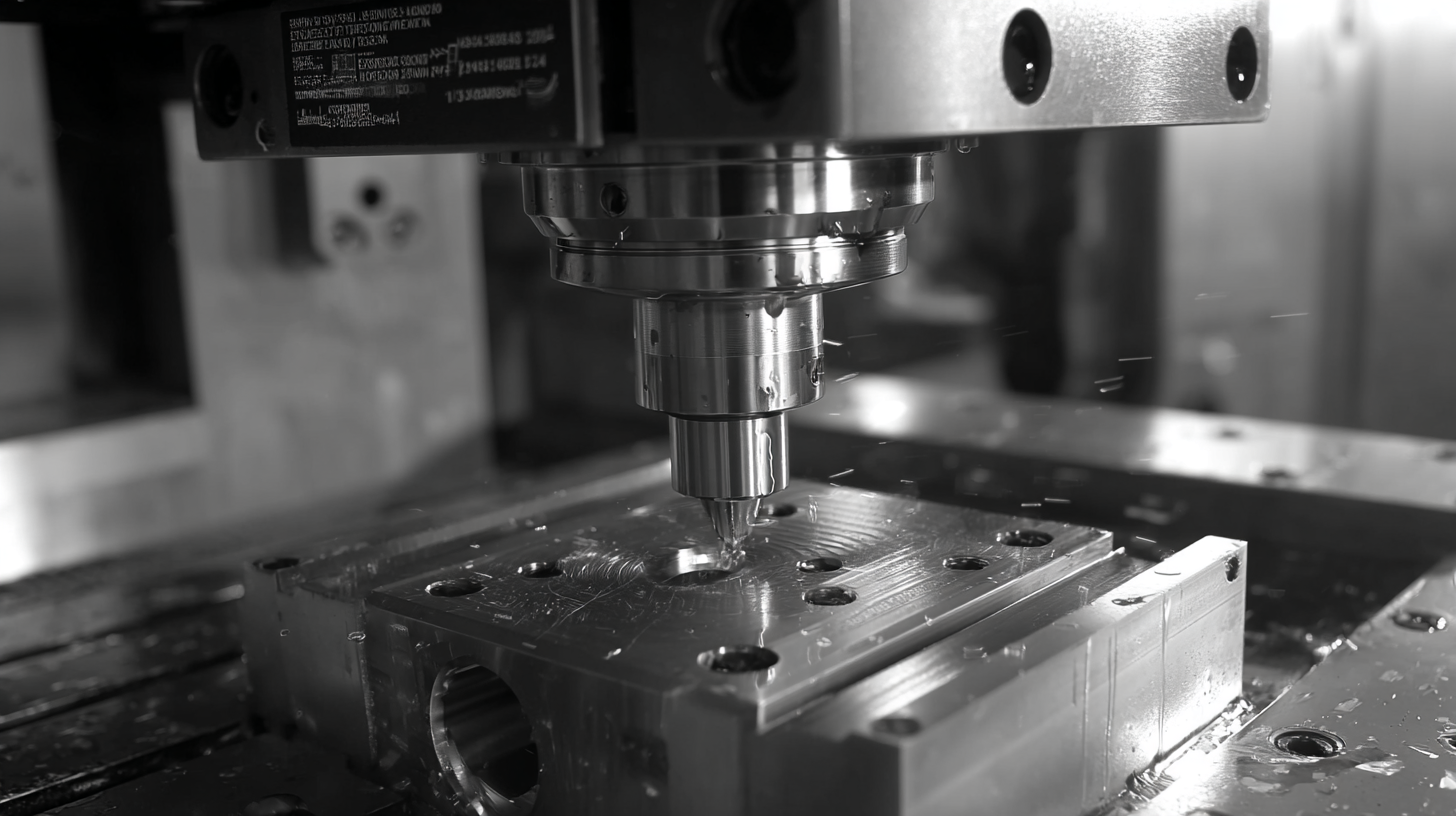

Finding Top Quality Suppliers for the Best Metal CNC Machines

In today's competitive manufacturing landscape, finding the right supplier for high-quality metal CNC machines is crucial for ensuring precision and efficiency in production processes. Metal CNC machines play a pivotal role in a variety of industries, from automotive to aerospace, and the effectiveness of these machines is heavily dependent on their manufacturer. This blog aims to guide you through the essential steps and criteria to consider when searching for top quality suppliers of metal CNC machines. By understanding the key factors such as supplier reputation, machine specifications, support services, and pricing strategies, you can make informed decisions that will enhance your operational capabilities and help maintain a competitive edge. Whether you're a seasoned expert in CNC machining or just starting out, this comprehensive guide will provide valuable insights to facilitate your supplier search with confidence.

Identifying Key Industries Utilizing Metal CNC Machines for Optimal Performance

The utilization of metal CNC machines spans various industries, showcasing their critical role in enhancing operational efficiency and product quality. According to a report by Research and Markets, the global CNC machine market size was valued at around $70 billion in 2021 and is projected to reach approximately $100 billion by 2026. This significant growth is driven primarily by industries such as aerospace, automotive, and electronics, which rely heavily on precision machining to meet rigorous quality standards and operational demands.

In the aerospace sector, for instance, CNC machining is imperative for producing complex components with tight tolerances. The Aerospace Corporation notes that parts manufactured using CNC machines can reduce production times by up to 30%, thus streamlining manufacturing processes. Similarly, the automotive industry adopts metal CNC technology to enhance the production of high-performance components, adapting quickly to design changes while maintaining efficiency. As per the International Data Corporation (IDC), companies leveraging advanced CNC machining processes can achieve up to 20% improvements in lead times, offering a competitive edge in the marketplace. The increasing adoption of these technologies in key industries signifies the essential nature of finding top-quality suppliers to support ongoing advancements in metal CNC machining.

Current Market Trends in CNC Machining: Supply and Demand Insights

The CNC machining market is currently experiencing significant growth, driven by increasing demand across various industries. As manufacturers seek to enhance productivity and precision, the focus has shifted towards

advanced metal CNC machines that offer superior capabilities. The market size is expanding, with an emphasis on

automated solutions that can cater to complex geometries, particularly in sectors like

automotive, general machinery, and aerospace.

Market trends indicate a rise in both supply and demand, with suppliers striving to meet the evolving requirements of manufacturers. Technological advancements in CNC tools, including both conventional and specialized machinery, are crucial for sustaining this growth. As the industry adapts to emerging needs, the segmentation of products into

metal cutting and

metal forming is becoming more pronounced, allowing for tailored solutions in precision machining applications. Regional insights reveal varied demands, influenced by local industrial activities, thus highlighting the necessity for suppliers to stay agile and responsive to market fluctuations.

Evaluating Supplier Quality: Metrics and Standards in the CNC Metal Industry

In the competitive landscape of CNC machining, evaluating supplier quality is paramount to ensuring the best outcome for your projects. Metrics such as on-time delivery rates, defect percentages, and customer satisfaction scores are crucial in assessing a supplier's reliability.

According to a report by the International Organization for Standardization (ISO), companies with robust supplier assessment programs tend to achieve 20% higher operational efficiency. These metrics not only reflect a supplier’s commitment to quality but also their ability to meet the specific needs of your CNC machining requirements.

Furthermore, industry standards such as ISO 9001 and AS9100 play a vital role in ensuring that suppliers adhere to consistent quality management practices. Research from the American Society for Quality indicates that organizations that implement standards like ISO 9001 can experience a 30% reduction in process variations. By prioritizing suppliers that comply with these metrics and standards, businesses can foster a reliable supply chain, reducing downtime and enhancing productivity in the CNC metal industry.

Case Studies: Successful Implementations of CNC Machines Across Various Sectors

In recent years, the implementation of CNC (Computer Numerical Control) machines has revolutionized various sectors, from automotive to aerospace. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2026, driven by the growing demand for precision engineering and automation in manufacturing. Case studies from industry leaders highlight the transformative impact of CNC technology. For instance, a major aerospace manufacturer reported a 30% increase in production efficiency after integrating CNC machines into their operations, showcasing the importance of quality suppliers in obtaining cutting-edge technology.

When seeking top-quality suppliers for CNC machines, it's essential to evaluate their track record in the industry. Look for suppliers with proven success stories, particularly those that have implemented CNC solutions in your specific sector. Additionally, consider the level of customer support and training they offer post-purchase, as this can significantly influence the success of your CNC implementation.

Tip: Always request case studies or references from potential suppliers to understand their experience and the effectiveness of their machines in real-world applications. Furthermore, assess the machine's scalability to ensure it aligns with your future growth plans.

The Future of CNC Machining: Innovations and Emerging Applications in Industry

The landscape of CNC machining is rapidly evolving, driven by innovative technologies and emerging applications across various industries. As businesses seek to enhance precision and efficiency, new advancements such as artificial intelligence and machine learning are becoming integral to CNC operations. These technologies allow for predictive maintenance, optimizing production processes, and significantly reducing downtime. By harnessing data analytics, manufacturers can now gain deeper insights into machine performance, leading to smarter decision-making and increased productivity.

Moreover, the rise of automation and robotics in CNC machining is transforming how products are manufactured. Automated systems not only streamline operations but also enhance the safety and consistency of production. Industries from aerospace to automotive are now utilizing advanced CNC machines that integrate seamlessly with robotic systems, offering unparalleled precision in complex tasks. With these innovations, the future of CNC machining holds promise for greater customization and responsiveness to market demands, allowing suppliers to meet the evolving needs of their clients with agility and efficiency.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.