How to Select the Right CNC Metal Solutions for Your Global Manufacturing Needs

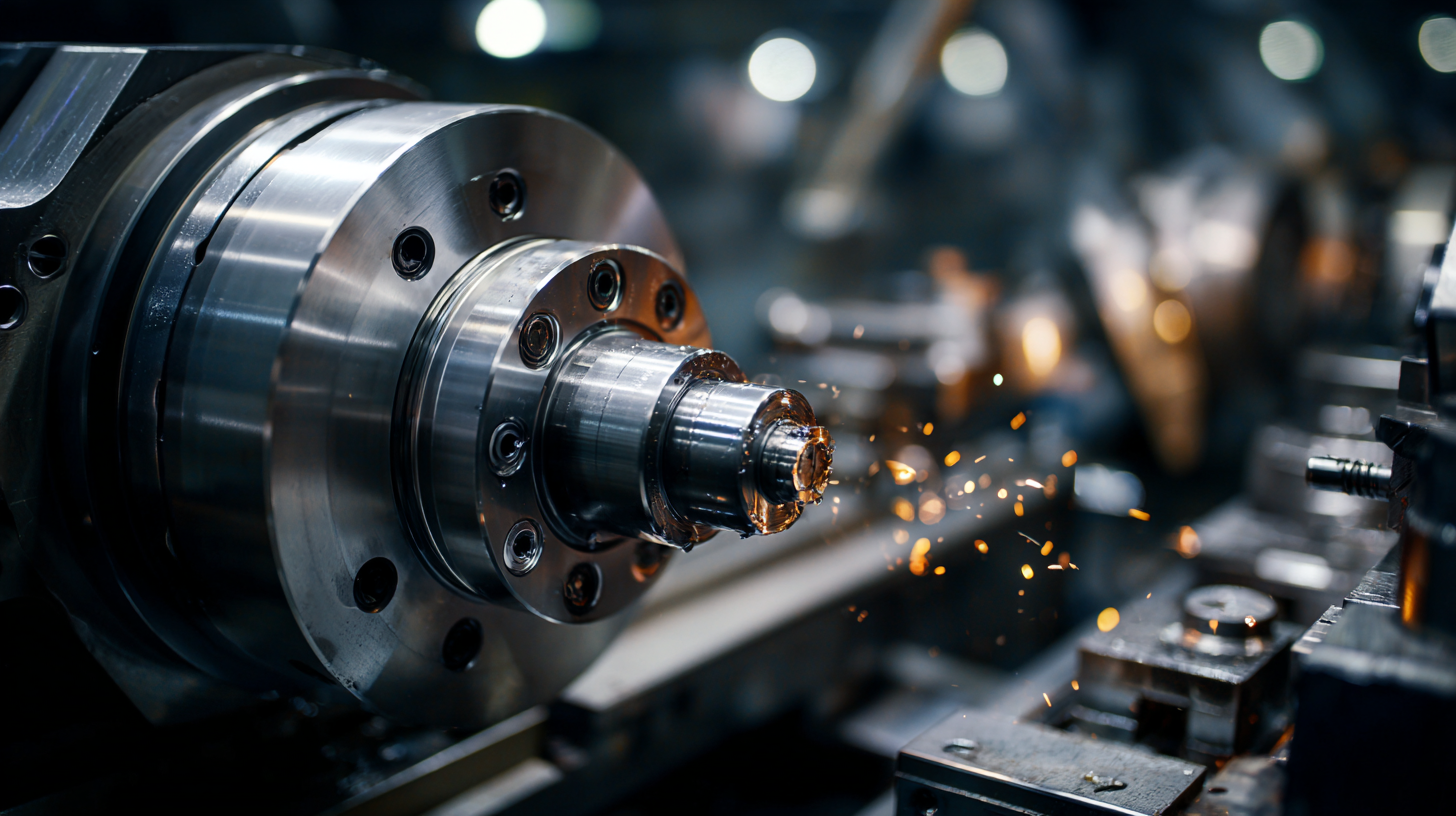

In today's interconnected world, selecting the right CNC metal solutions is crucial for global manufacturing success. As industries continue to evolve and demand for precision and efficiency rises, understanding the various CNC metal offerings has become more important than ever. This guide will explore the key factors to consider when choosing CNC metal solutions that align with your manufacturing needs. From assessing the capabilities of different CNC machines to evaluating the materials and processes involved, making informed decisions can significantly impact your production timeline and product quality.

Whether you are a seasoned manufacturer or venturing into CNC metal for the first time, this comprehensive overview aims to equip you with the knowledge necessary to navigate the complexities of CNC technology and optimize your operations on a global scale.

Assessing Your Global Manufacturing Requirements for CNC Metal Solutions

Assessing your global manufacturing requirements is crucial when selecting the right CNC metal solutions. According to a recent study by Mordor Intelligence, the global CNC machine market is projected to reach $100 billion by 2025, growing at a CAGR of approximately 6% from 2020. This surge emphasizes the need for manufacturers to critically evaluate their specific requirements, including production volume, material types, and design complexity. Industries such as aerospace and automotive, which demand high precision and quality, require CNC solutions that can handle stringent tolerances and various metal compositions.

Additionally, factors such as lead times, geographic location of suppliers, and material availability can significantly impact decision-making. A report from MarketsandMarkets indicates that 55% of manufacturers consider supply chain efficiency as a key criteria in their CNC machinery selection process. Understanding these variables can help businesses align their CNC capabilities with demand trends and operational goals, ensuring that the selected solutions not only meet current needs but are also scalable for future growth. Identifying regional advantages, such as proximity to raw materials or skilled labor pools, can further enhance manufacturing effectiveness in the global landscape.

Key Factors to Consider When Choosing CNC Metal Technologies

Selecting the right CNC metal solutions is crucial for businesses looking to enhance their manufacturing efficiency globally. As demand for high-precision tasks increases, integrating advanced digital manufacturing technologies can significantly boost productivity. According to industry reports, the global sheet metal fabrication service market is projected to reach a value of approximately $20.1427 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.57%, which could elevate the market size to around $32.1133 billion by 2033.

When choosing CNC metal technologies, companies should consider several key factors, including machine accuracy, operational costs, and environmental impact. Modern CNC machines designed with energy-efficient solutions not only help reduce operational expenses but also support sustainability initiatives. This transition from traditional methods to automated processes is essential to remain competitive in an evolving market. By focusing on these elements, manufacturers can ensure they select CNC solutions that align with their production goals while also adhering to the rising demand for eco-friendly practices.

Evaluating Supplier Capabilities and Market Reputation Worldwide

When selecting the right CNC metal solutions for global manufacturing needs, evaluating supplier capabilities and market reputation is crucial. According to a report by Grand View Research, the CNC machining market size is expected to reach $114.21 billion by 2028, growing at a CAGR of 6.2% from 2021. This growth indicates a competitive landscape where manufacturing companies must prioritize suppliers that have proven their capabilities and are recognized for their quality standards.

To assess supplier capabilities effectively, manufacturers should look for certifications such as ISO 9001 and AS9100, which demonstrate a commitment to quality management and industry-specific standards. Additionally, a survey by the Deloitte Insights highlights that 70% of executives believe that collaboration with reputable suppliers can enhance operational efficiency and innovation. It's vital to engage with suppliers who possess advanced technology, skilled workforce, and robust processes to ensure that they can meet both current and future demands.

Market reputation plays a pivotal role as well. Companies like McKinsey & Company emphasize the importance of supplier reviews and ratings in their studies, noting that positive feedback from current clients can significantly reduce procurement risks. Engaging in thorough research and leveraging industry networks can provide insights into suppliers’ track records, ensuring that manufacturers make informed choices that align with their global production goals.

Cost-Effectiveness and Efficiency in CNC Metal Manufacturing

Selecting the right CNC metal solutions for global manufacturing demands not only focuses on precision and quality but also prioritizes cost-effectiveness and efficiency. The objective is to streamline operations while minimizing material waste and labor costs. By opting for advanced CNC technology, manufacturers can significantly reduce production time, as these machines automate complex tasks that traditionally require extensive manual labor. The ability to program these machines for repeated tasks ensures consistency in output, helping to maintain quality while lowering overall expenses.

Additionally, leveraging high-performance CNC systems can lead to longer tool life and reduced downtime, further contributing to efficiency gains. When evaluating CNC services, look for providers that offer tailored solutions for your specific needs and possess experience in managing large-scale operations across various industries. Emphasizing cost-effective strategies, such as bulk purchasing of materials and optimizing machine settings, can lead to substantial savings. By placing efficiency at the forefront, businesses can adapt quickly to market changes while ensuring they remain competitive in a global landscape.

Cost-Effectiveness and Efficiency in CNC Metal Manufacturing

Future Trends in CNC Technologies and Their Impact on Global Markets

In recent years, CNC technologies have been rapidly evolving, significantly shaping global markets. The CNC machine tool market is projected to grow from $132.63 billion in 2025 to $229.46 billion by 2032, with a compound annual growth rate (CAGR) of 8.1%. This growth reflects the increasing demand for precision manufacturing across various industries, including automotive, aerospace, and electronics.

When selecting CNC metal solutions, it's essential to stay ahead of these trends. Consider investing in machines that not only meet current production demands but also offer future-ready technologies. For instance, look for equipment that incorporates automation features, such as robotic integration, which can enhance productivity and efficiency.

Tip: Always assess the scalability of the CNC solutions you choose. Ensure they can adapt to your growing manufacturing needs over time. Additionally, keep an eye on emerging trends in CNC applications, such as advancements in software and processing speed, which can drastically improve output quality and reduce lead times. Staying informed about these capabilities can give your business a competitive edge in the evolving global marketplace.

How to Select the Right CNC Metal Solutions for Your Global Manufacturing Needs - Future Trends in CNC Technologies and Their Impact on Global Markets

| Dimension | Current Trends | Future Predictions | Impact on Global Markets |

|---|---|---|---|

| Automation | Increased adoption of robotic systems and automation technologies | Higher efficiency with reduced labor costs | Enhanced competitiveness in local markets |

| Material Innovation | Growth in the use of advanced materials like composites | Development of lighter and stronger materials for manufacturing | Diversified product offerings in global markets |

| Sustainability | Increased focus on sustainable manufacturing practices | Government regulations driving eco-friendly processes | New market opportunities for green technologies |

| Industry 4.0 | Integration of IoT in CNC machining | Data-driven decision making and predictive maintenance | Increased global collaboration and innovation |

| Cost Efficiency | Demand for cost-effective manufacturing solutions | Improved processes leading to lower production costs | Greater access to global markets for small to medium enterprises |

Related Posts

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

-

Unlocking Precision: The Advantages of CNC Metal Machining in Modern Manufacturing

-

Exploring the Top Examples of Large CNC Machines for Global Buyers

-

Understanding CNC Machine Working Principles and Their Applications

-

10 Essential Tips for Optimizing CNC Machine Working Efficiency in Your Factory

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.