Unlocking Efficiency: How Metal CNC Machines Transform Modern Manufacturing Processes

The advent of advanced manufacturing technologies has revolutionized the production landscape, with metal CNC machines leading the charge in enhancing operational efficiency. According to a report by MarketsandMarkets, the global CNC machine market is expected to grow from USD 70.9 billion in 2020 to USD 100.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.6%. This surge is primarily fueled by the increasing demand for precision machining in various industries, such as aerospace, automotive, and medical devices.

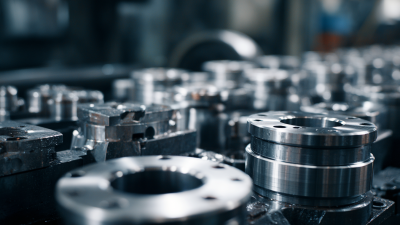

Metal CNC machines, which allow for high-speed and high-accuracy machining of complex components, are pivotal in meeting these demands. By automating the machining process, manufacturers can significantly reduce lead times and improve product quality, ultimately driving higher productivity and competitiveness in the modern manufacturing ecosystem. The integration of these machines not only streamlines operations but also fosters innovation, paving the way for the next generation of manufacturing solutions.

Metal CNC machines, which allow for high-speed and high-accuracy machining of complex components, are pivotal in meeting these demands. By automating the machining process, manufacturers can significantly reduce lead times and improve product quality, ultimately driving higher productivity and competitiveness in the modern manufacturing ecosystem. The integration of these machines not only streamlines operations but also fosters innovation, paving the way for the next generation of manufacturing solutions.

The Rise of Metal CNC Machines in Modern Manufacturing

The rise of metal CNC machines is reshaping the landscape of modern manufacturing, reflecting a robust growth trajectory in the industry. The global CNC machine market is projected to surge from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, achieving a compound annual growth rate (CAGR) of 9.9%. This significant expansion is driven by increased demands for precision and efficiency in manufacturing processes across various sectors, including automotive, aerospace, and consumer goods.

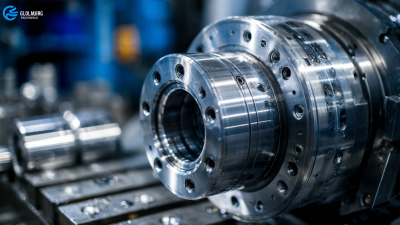

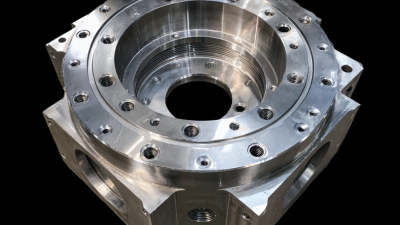

Recent advancements in CNC machining technology emphasize the importance of precision and quality. Companies, such as those in Appleton, Wisconsin, are focusing on enhancing their capabilities to produce high-quality stainless steel components. Moreover, other segments, like 5-axis CNC machining centers, are expected to witness substantial growth, projected to expand by USD 792.5 million from 2024 to 2028.

This evolution highlights the integration of self-optimized machine cutting and advanced AI technologies, which further streamline operations and improve productivity in the manufacturing arena, marking a revolutionary phase in the industry.

Key Advantages of Metal CNC Technology in Production Efficiency

The integration of metal CNC technology in modern manufacturing processes has unlocked unprecedented levels of efficiency and precision. According to recent industry reports, CNC machining can improve productivity by up to 30%, allowing manufacturers to meet growing demands with a streamlined workflow. This efficiency is achieved through automation, which minimizes human error, enhances repeatability, and allows for complex designs to be produced with relative ease.

Moreover, the adoption of CNC machines offers significant benefits in terms of material utilization. Studies indicate that precision machining can reduce waste by as much as 10%, making it an environmentally friendly choice in manufacturing. As industries worldwide embrace digital manufacturing technologies, the shift towards CNC machining is further propelled by its ability to adapt to rapid changes in design specifications, ultimately leading to a more resilient production landscape that caters to ever-evolving market demands.

Unlocking Efficiency: How Metal CNC Machines Transform Modern Manufacturing Processes

| Key Advantages | Description | Impact on Production Efficiency |

|---|---|---|

| Increased Precision | CNC machines offer high precision and accuracy in machining operations. | Reduces waste and rework, resulting in cost savings. |

| Higher Production Speed | Automated processes lead to faster cycle times. | Increases output and meets demand more effectively. |

| Reduced Labor Costs | CNC machines require fewer operators compared to manual machines. | Saves on labor expenses while improving operational efficiency. |

| Flexibility and Versatility | Easily switch between different machining tasks with programming. | Enables quick adaptation to market changes and custom orders. |

| Consistent Quality | CNC machining ensures uniform quality across production runs. | Builds trust and satisfaction in customer relationships. |

| Lower Material Waste | Optimized cutting paths reduce scrap material. | Enhances sustainability and reduces costs associated with materials. |

Maximizing Precision: How CNC Machines Enhance Quality Control

CNC (Computer Numerical Control) machines have revolutionized quality control in modern manufacturing, ensuring a level of precision that is crucial for producing high-quality parts. According to a report by the International Journal of Advanced Manufacturing Technology, CNC machines can achieve tolerances as tight as ±0.005 inches, significantly outperforming traditional machining methods. This level of precision is essential for industries that require strict adherence to specifications, such as aerospace and medical devices, where even the slightest deviation can have serious implications.

Moreover, the integration of CNC technology has led to a reduction in human error, enhancing the overall quality of production. A survey by the National Association of Manufacturers found that companies utilizing CNC machining reported a 30% decrease in defects. This improvement not only boosts product reliability but also streamlines the manufacturing process, enabling quicker turnaround times. As manufacturers increasingly prioritize efficiency and excellence, the adoption of CNC machines is poised to become a defining feature of the industry, compelling businesses to invest in these technologies to maintain competitive advantage.

Integrating Automation: The Future of Metal CNC Workflows

In the rapidly evolving landscape of manufacturing, automation plays a pivotal role in shaping the future of metal CNC workflows. The integration of robotics and advanced CNC technologies leads to improved efficiency, precision, and versatility in production processes. As industries increasingly adopt automated metal CNC machines, the potential for optimizing workflows expands dramatically. Automation streamlines operations, reduces human error, and allows for continuous production, creating a seamless transition from design to finished product.

As the manufacturing sector looks towards 2030, the expectation for significant advancements in automation is palpable. Metal sheet bending and CNC robotics are at the forefront of this evolution, projected to see substantial market growth. This evolution signals a shift towards more sophisticated manufacturing solutions that can handle complex designs with ease.

Tips: When considering automation in your manufacturing processes, start small by integrating simple robotics solutions to handle repetitive tasks. Gradually scale up to more complex CNC machines as you assess improvements in efficiency. Additionally, invest in training for your workforce to adapt to these new technologies, ensuring they can leverage the full potential of automated systems. Embracing these changes now will position your business competitively for the future.

Tips for Choosing the Right CNC Machine for Your Manufacturing Needs

Choosing the right CNC machine is crucial for optimizing manufacturing processes across various industries. With the rise of digital manufacturing technologies, businesses are increasingly seeking solutions that enhance productivity while minimizing operational costs. When selecting a CNC machine, it's essential to consider factors such as precision, material compatibility, and automation capabilities. Different types of CNC machines are designed for specific tasks, so understanding the requirements of your projects can guide your decision.

Moreover, evaluating the machine's adaptability to current trends can provide a competitive edge. As industries evolve, the integration of environmentally friendly solutions and high-efficiency designs is becoming more important. By investing in machines that offer these features, manufacturers can ensure they remain ahead in the market. Exploring emerging CNC project ideas can also reveal lucrative opportunities while expanding your capabilities within the sector. Embracing these tips can help you make an informed choice for your manufacturing needs, ultimately transforming your production processes for the better.

Related Posts

-

Exploring the Top Examples of Large CNC Machines for Global Buyers

-

Overcoming the Common Challenges in Sourcing the Best CNC Metal Milling Machines

-

Mastering the Art of Selecting the Best Machining Parts for Your Global Supply Chain

-

Global Market Insights on Best Machining Parts Trends for 2025

-

Global Quality Revolution in Best Large Part CNC Machining Made in China

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.