7 Key Factors That Elevate Your Success in Best Precision Machining Today

In today's competitive landscape, the significance of precision machining cannot be overstated, as it plays a pivotal role in various industries, from aerospace to medical devices. As technology advances and demands for higher quality standards increase, understanding the key factors that contribute to success in precision machining becomes essential for professionals and businesses alike. This blog will explore seven crucial elements that can elevate your success in the realm of precision machining, highlighting best practices, innovative techniques, and the importance of adopting cutting-edge technologies. By focusing on these aspects, you can enhance operational efficiency, improve product quality, and ultimately gain a competitive edge in this ever-evolving field. Join us as we delve into the critical components that define excellence in precision machining today.

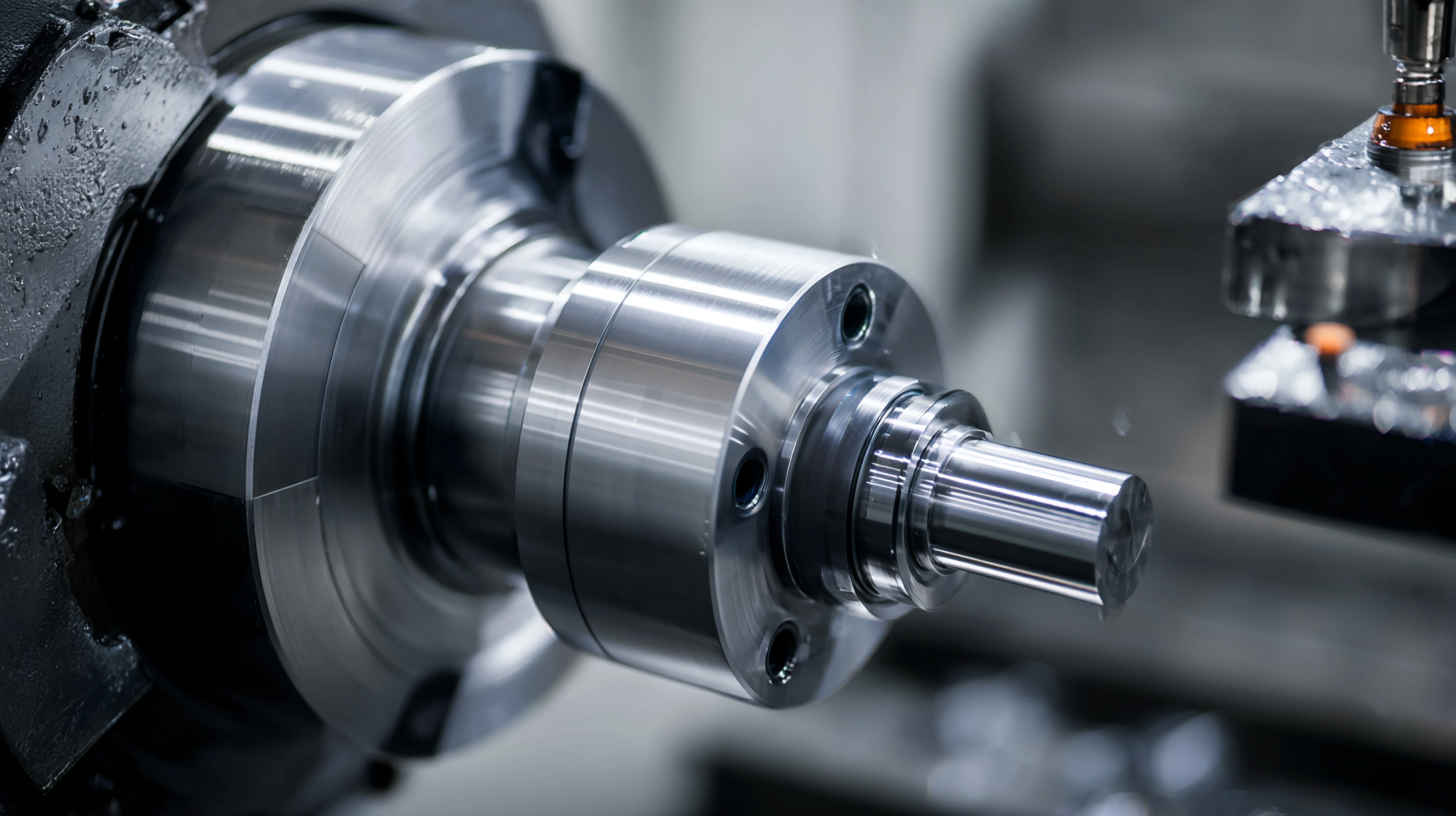

The Importance of Precision in Modern Machining Techniques

In the realm of modern machining, precision is not just a metric; it’s the cornerstone of success. As industries evolve and demands for quality increase, the importance of precision machining cannot be overstated. High precision can significantly reduce the margin of error, leading to superior product quality and enhanced customer satisfaction. This is especially vital in fields like aerospace, medical devices, and automotive manufacturing, where the slightest deviation can lead to catastrophic failures.

To achieve high precision in machining, adopting advanced technologies is essential. Computer Numerical Control (CNC) machines, for instance, allow for incredibly accurate cuts and shapes. Implementing real-time monitoring systems can also improve precision by enabling immediate adjustments during the machining process. Tips for maintaining high precision include regularly calibrating equipment and ensuring that all tools are properly maintained and sharp.

Moreover, investing in skilled machinists who understand the nuances of precision machining is equally important. Offering continuous training and embracing a culture of quality can significantly enhance the skill set of your workforce. Regularly reviewing production processes and seeking feedback can also lead to improvements in precision, ensuring that your machining operations stay ahead in today’s competitive landscape.

Innovative Technologies Enhancing Precision Machining Quality

In the rapidly evolving world of precision machining, innovative technologies play a pivotal role in enhancing quality and efficiency. Advanced computer numerical control (CNC) machines are at the forefront of this transformation. These machines utilize sophisticated algorithms and real-time feedback systems, allowing for intricate designs to be executed with extraordinary accuracy. By incorporating automation, manufacturers can reduce human error, streamline operations, and maintain consistent product quality, thereby elevating their success in this competitive industry.

Moreover, the integration of data analytics and the Internet of Things (IoT) is revolutionizing how precision machining processes are monitored and optimized. Real-time data collection enables machinists to identify potential issues before they escalate, ensuring minimal downtime and improved resource management. Additive manufacturing technologies, such as 3D printing, also complement traditional machining methods by allowing for rapid prototyping and complex geometries that were once deemed impossible. As these technologies continue to advance, they will undoubtedly pave the way for higher precision, lower costs, and a more agile manufacturing landscape, ensuring that companies remain at the forefront of the precision machining sector.

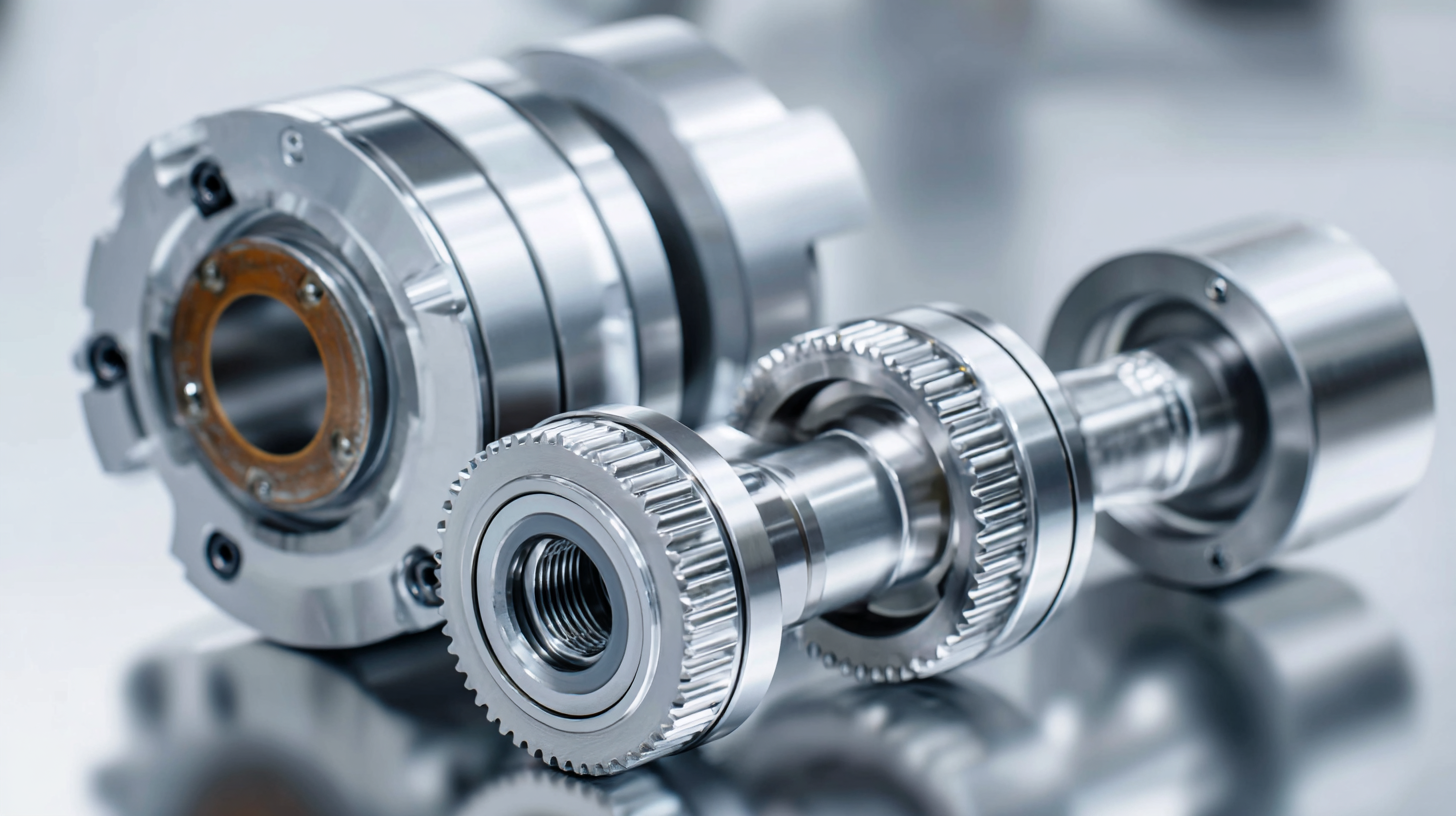

Key Materials That Boost Precision Machining Performance

When it comes to precision machining, the choice of materials is crucial in enhancing performance and achieving the desired outcome. One of the most reliable materials used in this field is high-speed steel (HSS). Renowned for its ability to retain hardness even at elevated temperatures, HSS is ideal for cutting tools, grinding machines, and drill bits. Its durability and resistance to wear allow for long machining cycles, which can significantly increase productivity and reduce downtime.

Another vital material that contributes to precision machining is carbide. Carbide tools are known for their exceptional hardness and ability to cut through tough materials with ease. These tools can operate at higher speeds and feed rates compared to conventional tools, making them suitable for high-volume production. Furthermore, the use of advanced coatings on carbide due to their low friction properties improves wear resistance and extends tool life, providing manufacturers with a more efficient and cost-effective solution in precision machining tasks. Selecting the right materials not only influences the quality of the final product but also impacts the machining process itself, leading to better overall performance.

The Role of Skilled Workforce in Achieving Machining Excellence

The modern landscape of precision machining is heavily influenced by the skilled workforce, which remains a pivotal factor in achieving machining excellence. In today’s competitive environment, having a team of highly trained professionals who understand the intricacies of advanced machinery and technology is vital. These individuals not only enhance productivity but also ensure that quality standards are met consistently. As industries adopt more complex technologies like AI and machine learning, the talent pool's adaptability and expertise become crucial to leverage these innovations for operational excellence.

Furthermore, the integration of generative AI and other advanced technologies into machining processes is reshaping the workforce's role. Skilled technicians are now required to harness these tools effectively, transforming them from traditional operators to strategic problem solvers. This evolution underscores the need for ongoing professional development, as organizations that invest in their people often see improved efficiencies and greater competitive advantages. By empowering their workforce with the right skills and technologies, companies can secure a brighter future in precision machining, driving both innovation and quality in the manufacturing sector.

Cost Efficiency: How Precision Machining Drives Business Success

Cost efficiency plays a pivotal role in the success of businesses utilizing precision machining. In today’s competitive landscape, companies constantly seek ways to optimize operations while minimizing expenses. Precision machining offers unmatched accuracy and consistency, enabling manufacturers to reduce material waste and lower production costs. By employing advanced technologies and methods, such as CNC machining and automated processes, businesses can produce high-quality components with less time and fewer resources.

Furthermore, the accuracy provided by precision machining not only enhances product quality but also fosters customer satisfaction and loyalty. When a company consistently delivers reliable and high-performance products, it builds a strong reputation in the market. This reliability translates into repeat business and the ability to charge premium prices, creating a sustainable revenue model. Overall, investing in precision machining not only streamlines production but also positions a business for long-term success through cost efficiency and enhanced quality.

7 Key Factors That Elevate Your Success in Best Precision Machining Today - Cost Efficiency: How Precision Machining Drives Business Success

| Factor | Description | Impact on Cost Efficiency | Statistical Improvement (%) |

|---|---|---|---|

| Technology Integration | Utilizing advanced machinery and software to enhance precision. | Reduces material waste through accurate cutting. | 30% |

| Skilled Workforce | Trained machinists and operators enhance product quality. | Minimizes errors and rework costs. | 25% |

| Lean Manufacturing | Streamlining operations to eliminate waste. | Improves production efficiency and reduces costs. | 20% |

| Quality Control | Regular inspections and tests to maintain standards. | Reduces the risk of defects and returns. | 15% |

| Supply Chain Optimization | Efficient sourcing and logistics management. | Lowers material costs and delivery times. | 18% |

| Predictive Maintenance | Anticipating equipment failure before it occurs. | Reduces downtime and increases productivity. | 22% |

| Client Collaboration | Engaging with clients for feedback and requirements. | Improves product alignment with customer needs. | 10% |

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.