Why is Precision CNC Essential for Modern Manufacturing?

In today's competitive manufacturing landscape, precision CNC plays a pivotal role. Industry expert John Smith emphasizes, "Precision CNC is not just a tool; it’s a pathway to innovation." This statement captures the essence of modern production techniques. Precision CNC enables manufacturers to achieve exact specifications, leading to higher quality products.

Manufacturers face many challenges, including tight tolerances and complex geometries. Precision CNC machines address these hurdles efficiently. However, the reliance on this technology can also lead to potential pitfalls. Over-dependence on automation can result in skill gaps among workers. Moreover, not all businesses can afford cutting-edge CNC systems, creating disparities in production capabilities.

Recognizing the importance of precision CNC is essential for growth. Companies that embrace this technology can reduce waste and enhance productivity. Yet, they must also reflect on their workforce's skills and training. Balancing technology with human expertise will likely drive future success in manufacturing.

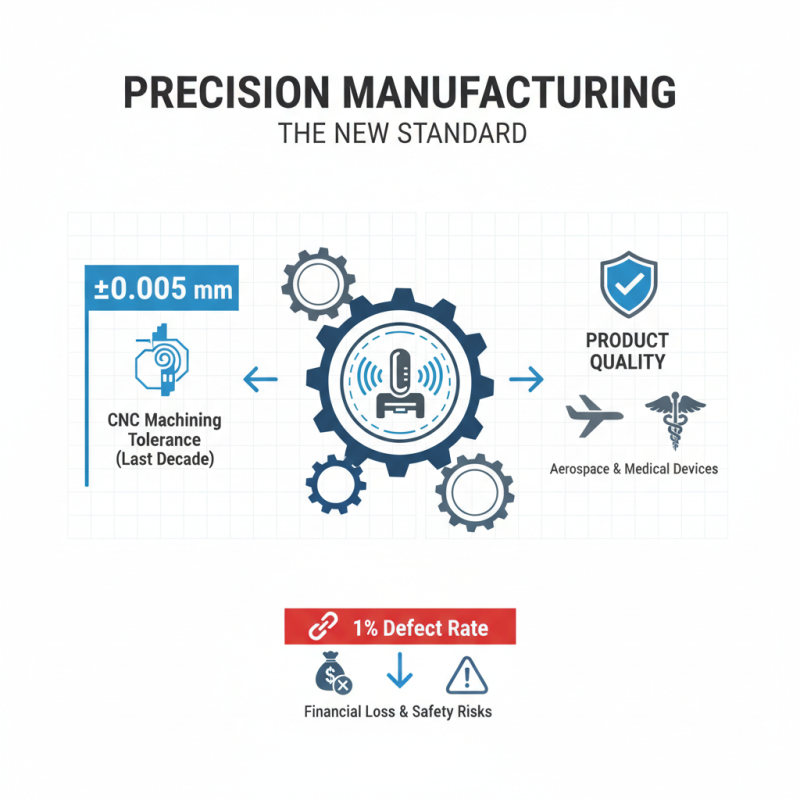

Importance of Precision in Manufacturing Processes

In the modern manufacturing landscape, precision is not just an option; it's a necessity. The average tolerance in CNC machining has tightened to as low as ±0.005 mm in the last decade. This level of precision directly correlates with product quality. Industries like aerospace and medical devices cannot afford deviations. A mere 1% defect rate can lead to heavy financial losses and safety risks.

Manufacturers often face challenges in achieving these precise measurements. Equipment wear, operator error, and material inconsistencies can contribute to discrepancies. A report from the National Institute of Standards and Technology indicates that up to 30% of manufacturers experience issues due to inadequate precision. Such shortcomings create waste and inefficiencies. It's crucial to invest in training and advanced technology to mitigate these risks.

Moreover, the push for reduced production cycles has led to a greater emphasis on precision. Today's consumers demand high-quality products with minimal lead times. A survey found that 88% of manufacturers believe precision directly affects customer satisfaction. Maintaining high standards is a continuous journey. Regular audits and updates are essential to adapt to evolving demands and technologies.

Key Advantages of CNC Technology in Modern Production

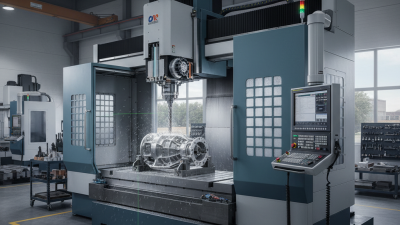

CNC technology revolutionizes modern manufacturing with its precision and efficiency. Traditional methods often involve human error. CNC machines, on the other hand, consistently deliver high accuracy. They operate based on computer-generated designs, minimizing the risk of mistakes. For example, a small error in a part can lead to major production issues later. CNC systems can produce complex shapes that human operators might struggle with.

Another key advantage is speed. CNC machines can run continuously without fatigue. This capability significantly increases production volume. Businesses can respond quickly to market demands, a critical factor today. However, understanding how to program these machines is essential. Not all operators grasp the complexities involved. Ongoing training is crucial for maximizing CNC benefits.

Cost efficiency is a notable aspect. CNC technology reduces material waste, which is a common issue with manual processes. Yet, the initial investment can be daunting for smaller companies. Many grapple with deciding if it's worthwhile. Over time, the lower operational costs usually justify the expense. Despite these advantages, the reliance on technology raises concerns about job displacement in traditional roles.

Why is Precision CNC Essential for Modern Manufacturing? - Key Advantages of CNC Technology in Modern Production

| Advantage | Description | Impact |

|---|---|---|

| High Precision | CNC machines can produce parts with tolerances of ±0.001 inches, ensuring high quality. | Improved product quality and reduced rework. |

| Increased Efficiency | CNC allows for faster production speeds and less manual labor. | Higher output rates and lower labor costs. |

| Flexibility in Design | Easily change designs and adapt to new specifications with minimal downtime. | Quick response to market demands. |

| Reduced Waste | CNC machining optimizes material usage, minimizing scraps. | Lower material costs and environmental impact. |

| Automation & Consistency | Automated processes ensure consistent output without variations. | Reduced errors and stable production quality. |

Applications of CNC Machining Across Various Industries

CNC machining is transforming various industries. Its precision ensures high-quality products, reducing waste and increasing efficiency. In aerospace, CNC plays a vital role in creating lightweight components. These parts require exact measurements, which CNC machines deliver.

In the automotive industry, CNC is used for manufacturing parts. It allows for complex shapes and tight tolerances. This adaptability is crucial for fitting engines and other essentials into vehicles. However, sometimes the initial designs can be flawed. Prototyping is key in this phase.

Tips: Always double-check specifications before production. Small errors can lead to significant issues. Regular maintenance of CNC machines is necessary. It prevents costly downtimes and enhances performance.

The medical sector also benefits from CNC machining. Custom implants and tools are produced with utmost precision. This personalization is vital for patient safety. However, achieving the desired outcomes often requires iterative design processes. Patience and attention to detail are essential here.

Adopting CNC technology can elevate any manufacturing process. The initial investment can be daunting. Yet, the long-term gains are worth exploring.

Applications of CNC Machining Across Various Industries

Impact of Precision CNC on Product Quality and Consistency

Precision CNC machining plays a vital role in enhancing product quality. It allows for high levels of accuracy. This technology can produce components with minimal tolerances. An engine part, for example, must fit together flawlessly. Any deviation can lead to performance issues. Consistent precision is crucial in the automotive industry.

Product consistency is another significant benefit of precision CNC. Parts made with CNC machines are uniform. This uniformity reduces the risk of defects. However, mistakes can still happen during the setup process. Additionally, variations in material can impact the final output. Workers must pay attention to every detail to ensure quality.

Precision CNC allows manufacturers to create complex designs. Geometry can be tricky, especially in tight spaces. Sometimes, the results may not meet expectations. This inconsistency can prompt a reevaluation of processes. Continuous improvement is essential in a competitive market. Manufacturers must always seek to refine their practices for better outcomes.

Future Trends in CNC Technology and Its Role in Manufacturing

CNC technology is evolving rapidly. In the near future, we can expect smarter machines that use artificial intelligence. These machines will enhance accuracy and efficiency. They will learn from data and improve their operations over time. This shift means manufacturers must adapt quickly to keep pace.

Tips: Always invest in training for your operators. Proper knowledge greatly enhances machine performance. Regular updates of software are also essential for accuracy.

Another key trend is the increase in automation. More processes will be automatic, reducing human errors. This leads to higher output and lower costs. However, reliance on devices may lead to skill gaps among workers. Manufacturers must find a balance between automation and human expertise.

Tips: Consider hybrid models that combine automation with skilled labor. This strategy can mitigate risks while boosting efficiency. Continuous assessment of your processes will help identify areas needing improvement. Embrace change but reflect on its impact on your workforce.

Related Posts

-

10 Best Large CNC Machines for Precision Engineering in 2023

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Choosing the Right Manufacturer for Best CNC Machine Fabrication Solutions You Can Trust

-

Discover Unmatched Quality in Best CNC Precision Machining from Leading Chinese Manufacturers

-

Understanding Common Issues in Precision CNC Machining Processes

-

Unlocking Precision: The Advantages of CNC Metal Machining in Modern Manufacturing

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.