Why is Metal Machining Important for Modern Manufacturing?

In the realm of modern manufacturing, the significance of metal machining cannot be overstated. According to Dr. Emily Carter, an expert in the metal machining industry, "Precision in metal machining lays the groundwork for innovation in manufacturing." Her words resonate with the core essence of how metal machining drives efficiency and quality.

Metal machining is essential for producing accurate components for various industries. It enables manufacturers to create parts that meet exact specifications. From aerospace to automotive, the applications of metal machining are vast. However, challenges persist. The demand for high precision may sometimes clash with cost-effectiveness. This tension requires constant reflection on methods and techniques used.

Moreover, the world of metal machining is evolving rapidly. Advanced technologies are reshaping traditional methods. Yet, the industry faces difficulties in adapting to these innovations. Balancing new tools with skillful craftsmanship remains a hurdle. Metal machining is a cornerstone of manufacturing, warranting continuous improvement and adaptation.

The Role of Metal Machining in Precision Engineering and Production

Metal machining plays a critical role in precision engineering and production. It transforms raw materials into precisely crafted components. According to a report by the American Society of Mechanical Engineers, about 70% of the manufacturing process relies on machining techniques. This emphasizes its significance in creating accurate parts for various industries, including aerospace and automotive.

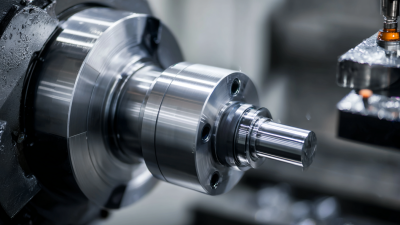

In precision engineering, machining ensures high tolerances. Components must fit perfectly together. A slight deviation can lead to failures or inefficiencies. For instance, modern CNC machines can achieve tolerances of less than 0.001 inches. However, achieving such accuracy often requires ongoing adjustments. Not all machines maintain these standards without comprehensive monitoring.

Despite advancements, challenges remain. The industry's workforce must be trained continuously. Labor shortages can impact productivity. Additionally, a 2023 study found that 25% of manufacturers report issues with machine maintenance, leading to downtime. Addressing these issues is vital for the effectiveness of precision machining. Striking a balance between technology and human oversight is essential for modern manufacturing success.

Impact of Metal Machining on Product Quality and Performance Metrics

Metal machining plays a crucial role in modern manufacturing. It directly affects product quality and performance metrics. According to a report by the American Society of Mechanical Engineers, precision machining can improve tolerances to within ±0.002 inches. Such accuracy ensures that parts fit together correctly, reducing the risk of failure in assembled systems.

Improved surface finish is another benefit. It reduces friction and wear in mechanical components. For instance, a smoother surface can increase the lifespan of a part by up to 30%. However, achieving this level of refinement can be challenging. Many manufacturers struggle with inconsistencies in machining processes, leading to variability in quality.

**Tip:** Regularly audit machining processes to identify areas for improvement. Training operators can enhance skills and boost precision. Investing in high-quality tools often pays off.

Performance metrics are vital for assessing product success. Inconsistent machining can lead to defects. A study by the National Institute of Standards and Technology revealed that quality issues often result in nearly 15% of total manufacturing costs. Addressing these issues is essential for maintaining competitiveness in the market.

**Tip:** Implement a feedback loop where operators report machining outcomes. This can foster a culture of continuous improvement. Collect data on performance metrics to track improvements over time.

Impact of Metal Machining on Product Quality and Performance Metrics

Statistics on Metal Machining's Contribution to Manufacturing Efficiency

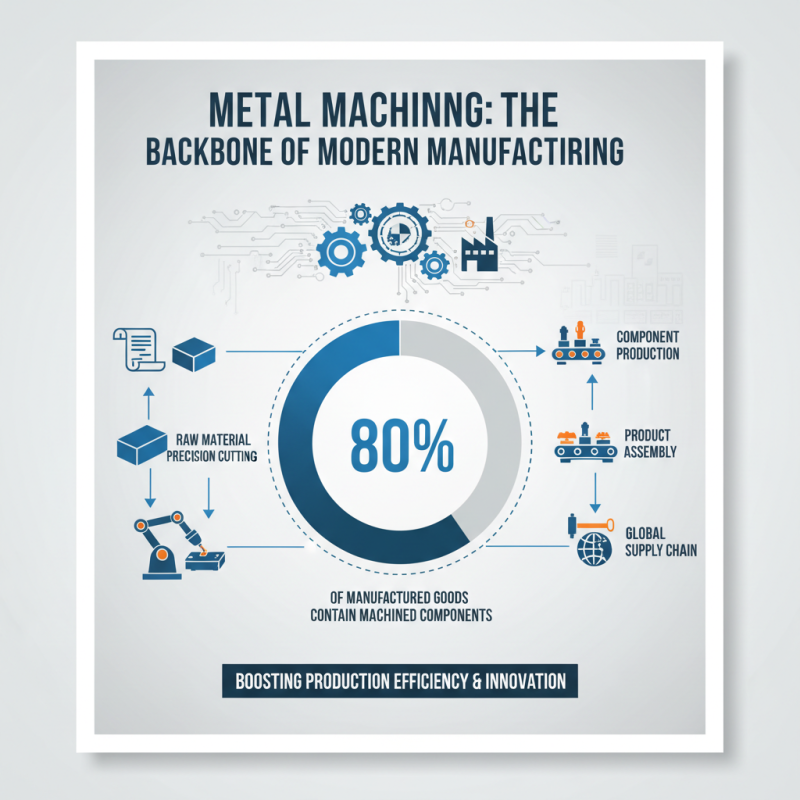

Metal machining plays a crucial role in modern manufacturing. Statistical data reveals its vast impact on production efficiency. In fact, over 80% of manufactured goods contain components made through machining processes. This highlights the vital importance of machining in the supply chain.

In terms of efficiency, precise machining can reduce production time by nearly 30%. This efficiency stems from its ability to create parts that fit together seamlessly. However, the cost of machinery can be a barrier for small manufacturers. Many struggle with the initial investment, which leads to missed opportunities. It’s a problem worth addressing.

Moreover, the waste generated during machining affects sustainability. Approximately 25% of materials get wasted during the process. While advancements in technology aim to reduce this, there’s still significant room for improvement. Companies must focus on innovative techniques to minimize waste. Emphasizing efficiency and waste reduction is critical for future growth in the manufacturing sector.

Key Industries Benefiting from Advanced Metal Machining Technologies

Metal machining plays a crucial role in various key industries today. The automotive industry greatly benefits from advanced machining technologies. They produce precise components, such as engine parts and gear systems, which are essential for vehicle performance. Precision machining also helps reduce waste and lower production costs. However, some manufacturers still struggle to adopt these technologies fully.

In the aerospace sector, metal machining is vital for creating lightweight and strong components. Parts like turbine blades require high accuracy. This ensures reliability under extreme conditions. Yet, not all companies have the resources to invest in the latest machinery. This can lead to discrepancies in quality and safety.

The medical field also relies on metal machining for creating surgical instruments and implants. Customization is key here, as every patient's needs differ. Unfortunately, some machining processes may prioritize speed over quality. This can result in inadequate tools that don’t meet necessary standards. Balancing efficiency and precision is a challenge many face.

Why is Metal Machining Important for Modern Manufacturing?

| Industry | Key Benefits of Metal Machining | Machining Techniques Used | Materials Commonly Machined |

|---|---|---|---|

| Aerospace | High precision components, weight reduction | CNC Machining, EDM | Aluminum, Titanium |

| Automotive | Improved engine performance, fuel efficiency | Milling, Turning | Steel, Aluminum |

| Medical Devices | High accuracy, biocompatibility | Laser Cutting, CNC Machining | Stainless Steel, Plastics |

| Electronics | Compact design, heat dissipation | CNC Milling, Laser Engraving | Copper, Aluminum |

Future Trends in Metal Machining: Automation and Smart Manufacturing

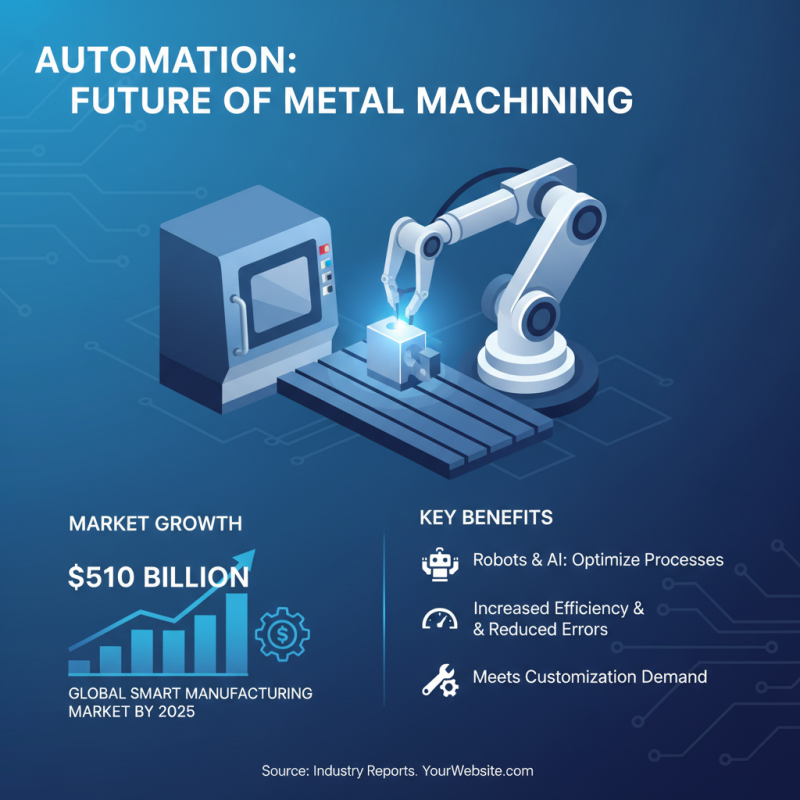

Automation is transforming metal machining. According to industry reports, the global smart manufacturing market is projected to reach $510 billion by 2025. This growth shows how companies are investing in automated solutions. Robots and AI optimize processes, increasing efficiency and reducing errors. Traditional methods struggle to keep up with the demand for customization.

Tips: Embrace automation. Start small. Focus on specific tasks like quality control. Gradually expand to integrated solutions.

The integration of smart technologies facilitates real-time data analytics. Machines can now predict maintenance needs, reducing downtime by 30%. However, the transition has challenges. Companies must train employees and ensure seamless operation. Resistance to change can hinder progress. Leaders should foster a culture of adaptability.

Tips: Provide ongoing training. Engage employees in the transformation process. Encourage feedback to address concerns.

The trend toward automation and smart systems isn’t without drawbacks. High initial costs can deter smaller manufacturers. It’s essential to weigh the long-term benefits against these short-term investments. Future success hinges on balancing technology adoption with human expertise.

Related Posts

-

Ultimate Checklist for Achieving the Best Metal Machining Results

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

-

The Future of Precision Engineering: Innovations in Best CNC Parts Production

-

7 Key Factors That Elevate Your Success in Best Precision Machining Today

-

Navigating the Future: 2025 Market Insights for Best Precision Machining with Essential Strategies Revealed

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.