Global Quality Revolution in Best Large Part CNC Machining Made in China

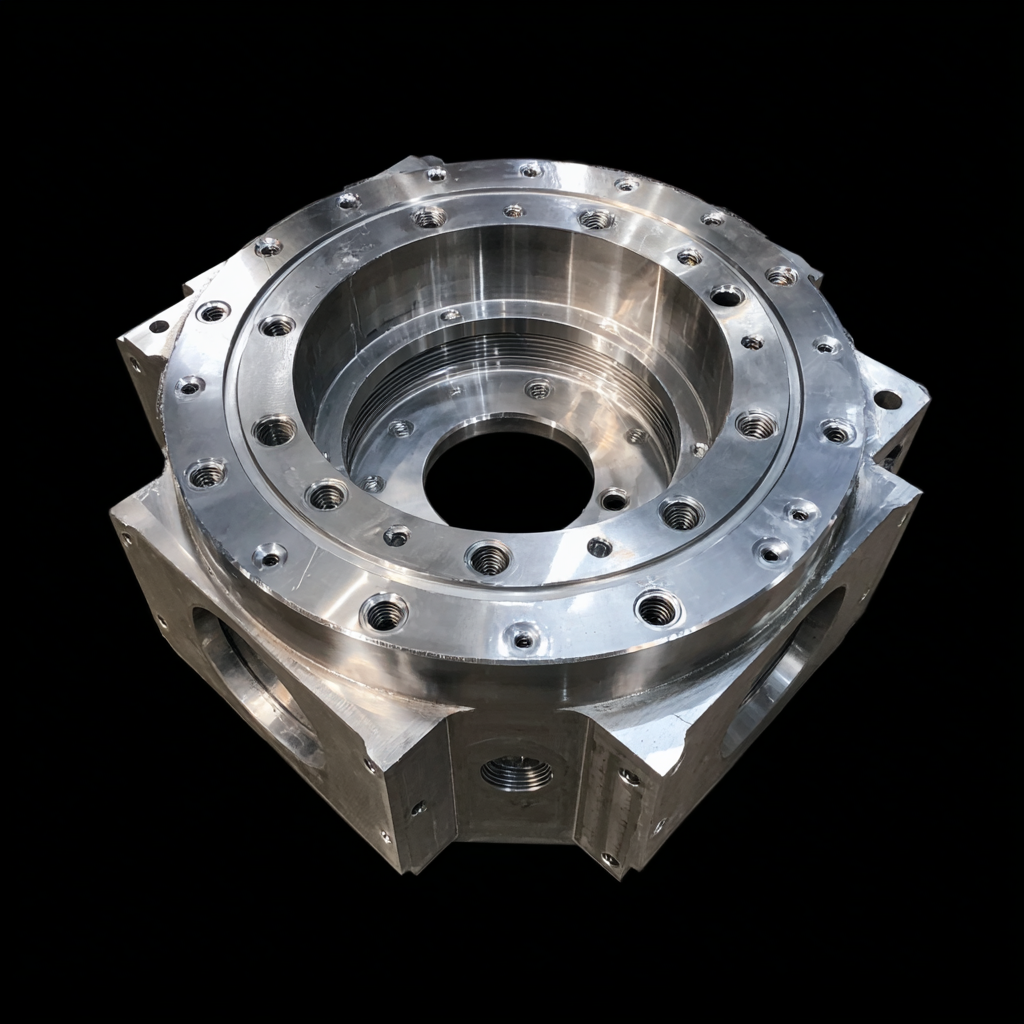

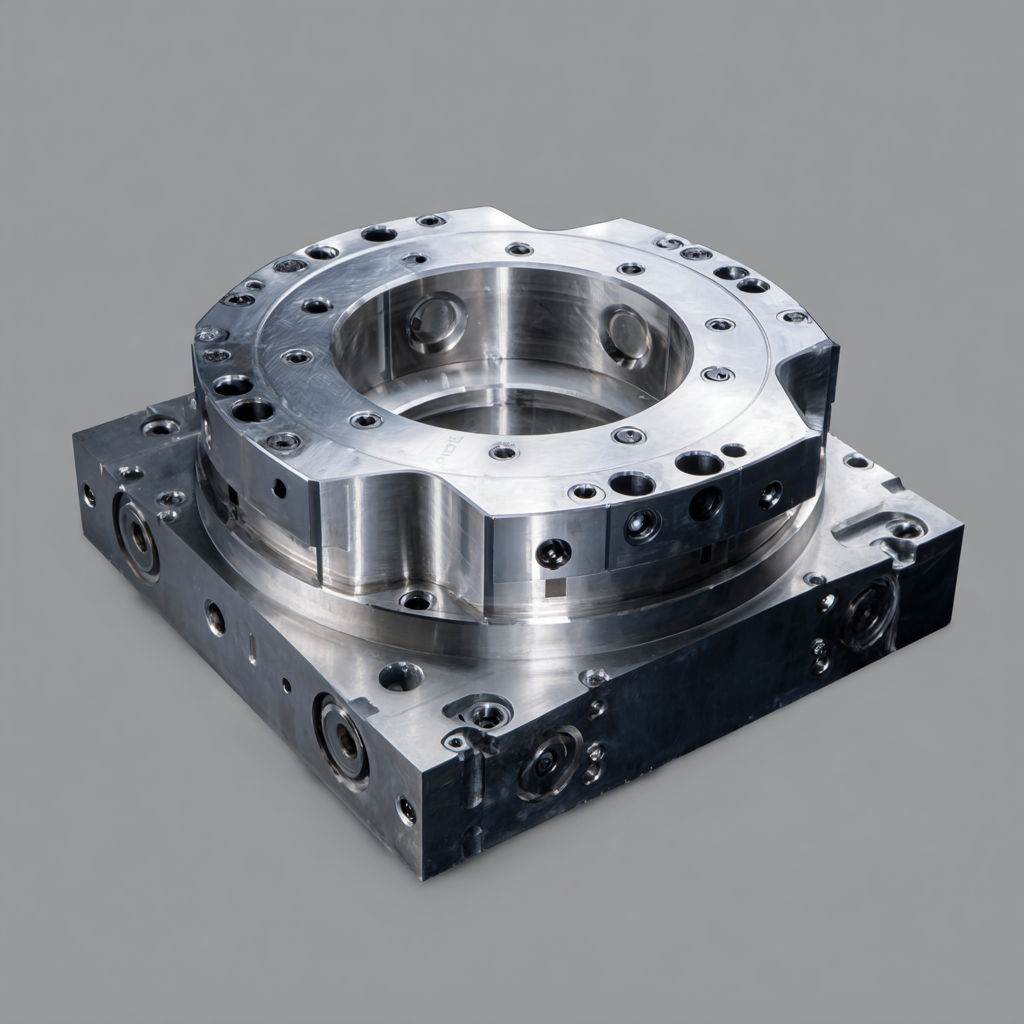

In recent years, the landscape of manufacturing has undergone a significant transformation, particularly in the realm of large part CNC machining. As industries around the globe seek precision and efficiency, China has emerged as a formidable leader in this sector, revolutionizing the way large components are produced. This blog explores the intricate details of product specifications related to large part CNC machining, emphasizing the technological advancements and quality control measures that enhance production outcomes.

Additionally, we will delve into practical guides on optimizing the machining process, ensuring that manufacturers can harness the full potential of these large-scale operations. Join us as we uncover the foundations of this quality revolution and its implications for future manufacturing practices.

Challenges Facing Large Part CNC Machining in China Today

In recent years, large part CNC machining in China has encountered significant challenges that impact its overall quality and efficiency. One of the primary obstacles is the disparity in technology adoption across different manufacturers. While some companies invest heavily in advanced machinery and training, others lag behind, leading to inconsistencies in output quality. Furthermore, a shortage of skilled labor exacerbates this issue, as the demand for proficient operators exceeds supply, compromising the machining process.

To overcome these hurdles, manufacturers can take proactive steps. **Tip 1:** Implementing a comprehensive training program can equip workers with necessary skills, ensuring they are proficient in using the latest CNC technologies. **Tip 2:** Collaboration with technology providers can facilitate knowledge transfer and help companies stay updated with industry trends. By fostering a culture of continuous improvement, organizations can enhance their competitiveness on a global scale.

Another pressing concern is the increasing emphasis on quality standards. Many international clients are now demanding tighter tolerances and adherence to stringent quality management systems. **Tip 3:** Establishing a robust quality assurance process, including regular audits and feedback loops, can help manufacturers meet these rising expectations and establish their reputation for excellence in large part CNC machining.

Technological Gaps in Global CNC Machining Standards

The global CNC machining industry is at a pivotal juncture as technological advancements are reshaping standards across the board. Despite China's rise as a leading innovator in advanced industries, significant gaps remain in the global CNC machining standards. These disparities are critical, especially when considering the exceptional growth projected in the CNC machine market, expected to reach $195.59 billion by 2032. The rapid evolution in technologies such as AI and machine learning is paving the way for improved air quality forecasting and sustainable production practices, but it also highlights the urgent need for internationally recognized benchmarks in CNC machining.

As China's capabilities in innovation expand, the challenge lies in aligning its manufacturing standards with global expectations. The demand for precision and efficiency in CNC machining is paramount, and emerging technologies offer an opportunity to bridge existing gaps. By adopting best practices and integrating cutting-edge technologies, Chinese manufacturers can enhance their global competitiveness. This not only strengthens China's position but also sets a precedent for others in the industry to follow, fostering a unified approach to quality standards worldwide.

Quality Control Issues in Chinese CNC Machining Operations

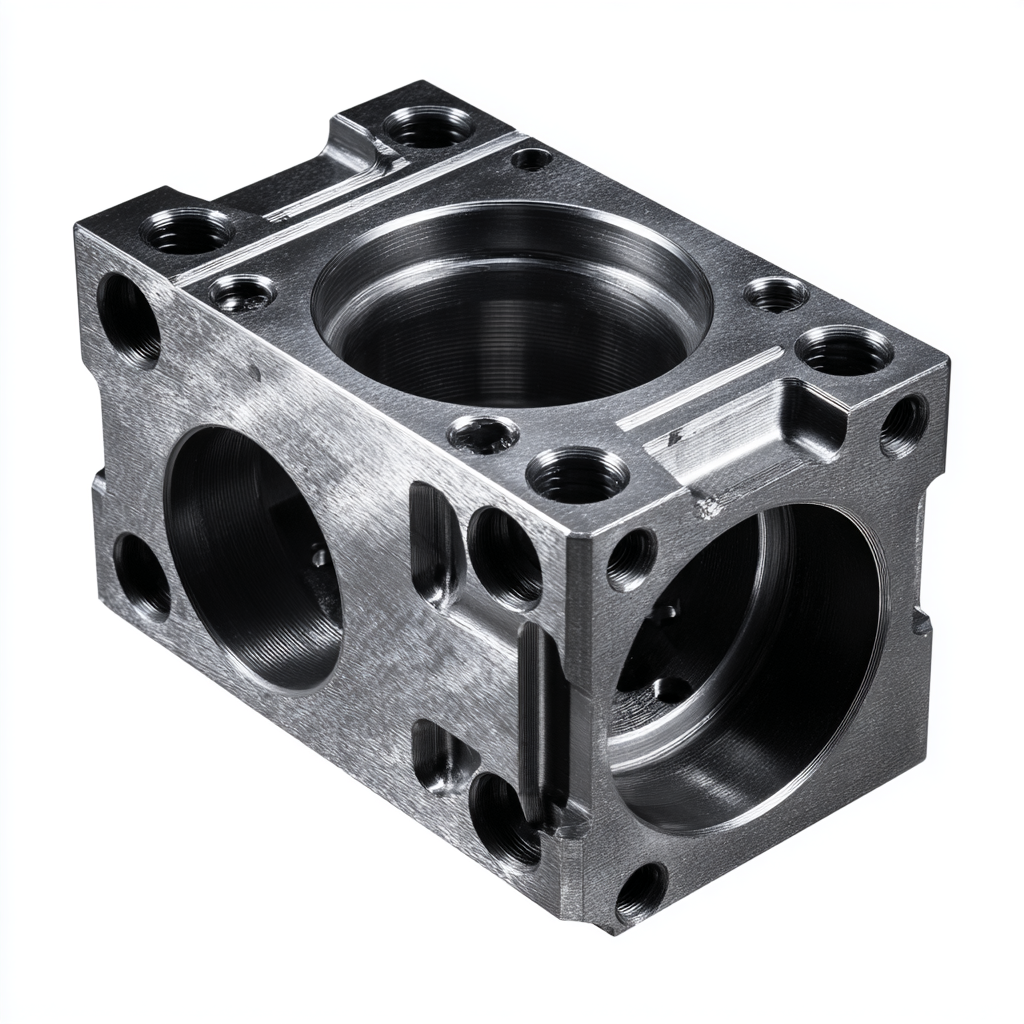

The rise of the 4th Industrial Revolution has ushered in innovative quality control measures in CNC machining operations, particularly in China. A key advancement in this realm is the implementation of automatic data collecting systems, such as the touch probing system integrated into CNC machine tools. This technology significantly enhances the accuracy of machining operations by providing real-time data feedback, allowing manufacturers to address quality control issues proactively. By continually monitoring and assessing machining processes, companies can ensure that products meet stringent quality standards, ultimately driving the global shift towards superior manufacturing practices.

Moreover, the challenges faced by Chinese CNC machining operations in mastering high-end technologies highlight the importance of robust quality assurance strategies. The ability to leverage advanced technologies, like machine vision systems and intelligent fault detection methods, will play a critical role in ensuring consistent product quality. As industries push towards automation and smart manufacturing solutions, embracing these innovative quality control techniques will be vital in overcoming existing shortcomings and advancing China’s capabilities in high-precision machining. The commitment to enhancing quality through technological integration reflects a larger shift in manufacturing paradigms aimed at achieving excellence on a global scale.

Global Quality Revolution in Best Large Part CNC Machining Made in China - Quality Control Issues in Chinese CNC Machining Operations

| Quality Control Aspect | Challenges Faced | Current Solutions | Future Improvements |

|---|---|---|---|

| Raw Material Quality | Inconsistent quality from suppliers | Supplier audits and certifications | Establishing long-term supplier relationships |

| Machining Accuracy | Tolerance failures in production | Regular calibration of machines | Investment in high-precision machinery |

| Process Control | Lack of standardized processes | Implementation of ISO standards | Continuous process optimization initiatives |

| Defect Rate | High rate of post-production defects | Quality checks during production | Enhanced employee training and skill development |

| Delivery Timeliness | Frequent delays affecting customer satisfaction | Implementation of lean manufacturing principles | Advanced scheduling and logistics software |

The Impact of Global Competition on CNC Machining Practices

The landscape of CNC machining in China is undergoing a significant metamorphosis, primarily driven by global competition. As international players push for higher standards, Chinese manufacturers are compelled to elevate their machining practices, enhance quality, and innovate continuously. This shift has resulted in a wave of improvements across the industry, enabling firms to meet and even exceed global quality expectations.

To keep up in this competitive environment, companies must focus on adopting cutting-edge technologies. Implementing advanced CNC machines and leveraging automation can dramatically boost efficiency and precision. Additionally, investing in workforce training ensures that employees are adept at using these new tools, fostering a culture of excellence within the organization.

Moreover, collaboration and knowledge exchange with international partners can provide invaluable insights into best practices. Networking at global trade shows or joining industry forums can open doors to new techniques and methodologies that enhance overall production quality. Emphasizing a customer-centric approach by gathering feedback also helps manufacturers tailor their products to meet diverse market demands successfully.

Strategies for Improving CNC Machining Quality in China

The CNC machining industry in China is on the brink of a quality revolution.

As global demand for precision and reliability increases, Chinese manufacturers must adopt innovative strategies

to enhance the quality of their machining processes. One key strategy involves investing in advanced technology

and equipment. By upgrading machinery to state-of-the-art CNC systems, manufacturers can improve their precision and efficiency,

ultimately leading to higher product standards.

Tips for quality improvement include implementing comprehensive training programs

for operators and engineers. A well-trained workforce is crucial for maintaining high-quality standards in CNC machining.

Regular workshops and hands-on training sessions can equip personnel with the skills needed to operate complex machinery

and troubleshoot issues effectively.

Another vital aspect is establishing rigorous quality control measures throughout

the production process. This includes regular inspections and testing of parts to catch defects early. Implementing automated

quality checks using software and data analytics can significantly reduce errors and enhance overall product reliability.

By fostering a culture of quality and continuous improvement, Chinese CNC machining

companies can compete effectively on a global scale.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.