Global Market Insights on Best Machining Parts Trends for 2025

As we look ahead to 2025, the global market for machining parts is poised for significant transformation, driven by technological advancements and evolving industry demands. This blog delves into the key trends that are shaping the future of machining parts, providing insights into the innovations and practices that will enhance productivity and efficiency.

The integration of digital technologies, such as automation and AI, is revolutionizing production processes, allowing for greater precision and customization. Furthermore, shifts in consumer preferences and sustainability initiatives are compelling manufacturers to adapt and innovate. In this exploration, we will uncover the reasons behind these trends, highlighting how they will redefine the landscape of machining parts, enable competitive advantages, and set the stage for a new era of manufacturing excellence.

Join us as we navigate the complex and dynamic world of machining parts to understand what the future holds.

Key Factors Driving Machining Parts Innovation in Global Markets

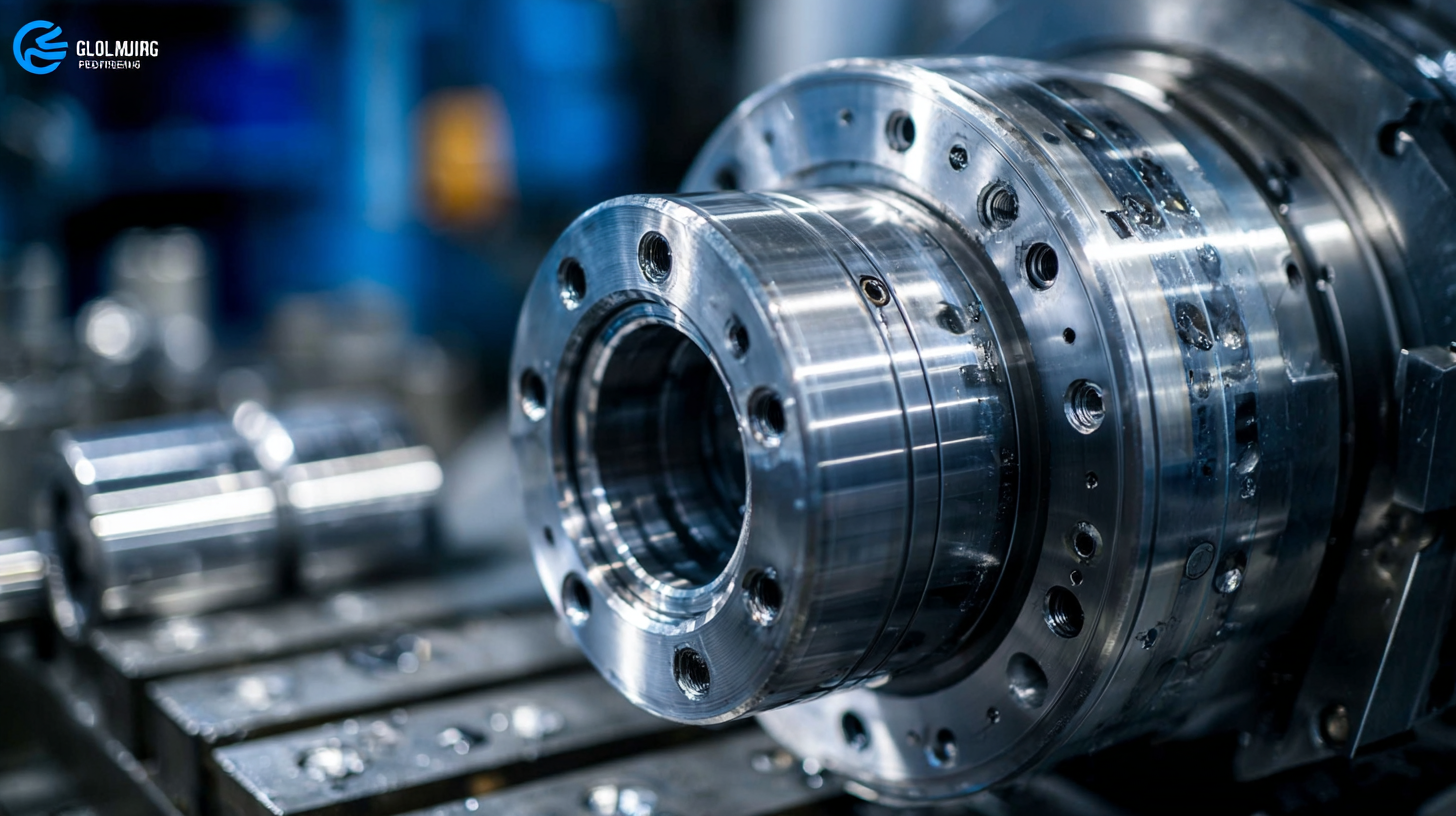

The global market for machining parts is poised for significant innovation driven by several key factors. As industries evolve, the demand for precision-engineered components is surging, especially in sectors like aerospace, automotive, and medical devices. Technologies such as CNC machining and laser cutting are becoming integral in manufacturing highly accurate parts. This shift is evident in the projected growth of the precision components market, anticipated to expand substantially through 2025 and beyond.

Moreover, advancements in materials science, particularly the increase in demand for titanium alloys and stainless steels, are spurring innovation in machining processes. The titanium market is projected to grow from $6.17 billion in 2025 to $10.23 billion by 2033. This growth is reflective of a broader trend towards lightweight yet durable materials, essential for modern engineering applications. In parallel, the automotive remanufacturing sector is expected to see robust growth, reaching $33.68 billion by 2032, driven by sustainability initiatives and the need for cost-effective solutions in vehicle production. As we move towards 2025, companies focusing on these trends will play a crucial role in shaping the future of machining technology.

Emerging Technologies Shaping the Future of Machining Parts Manufacturing

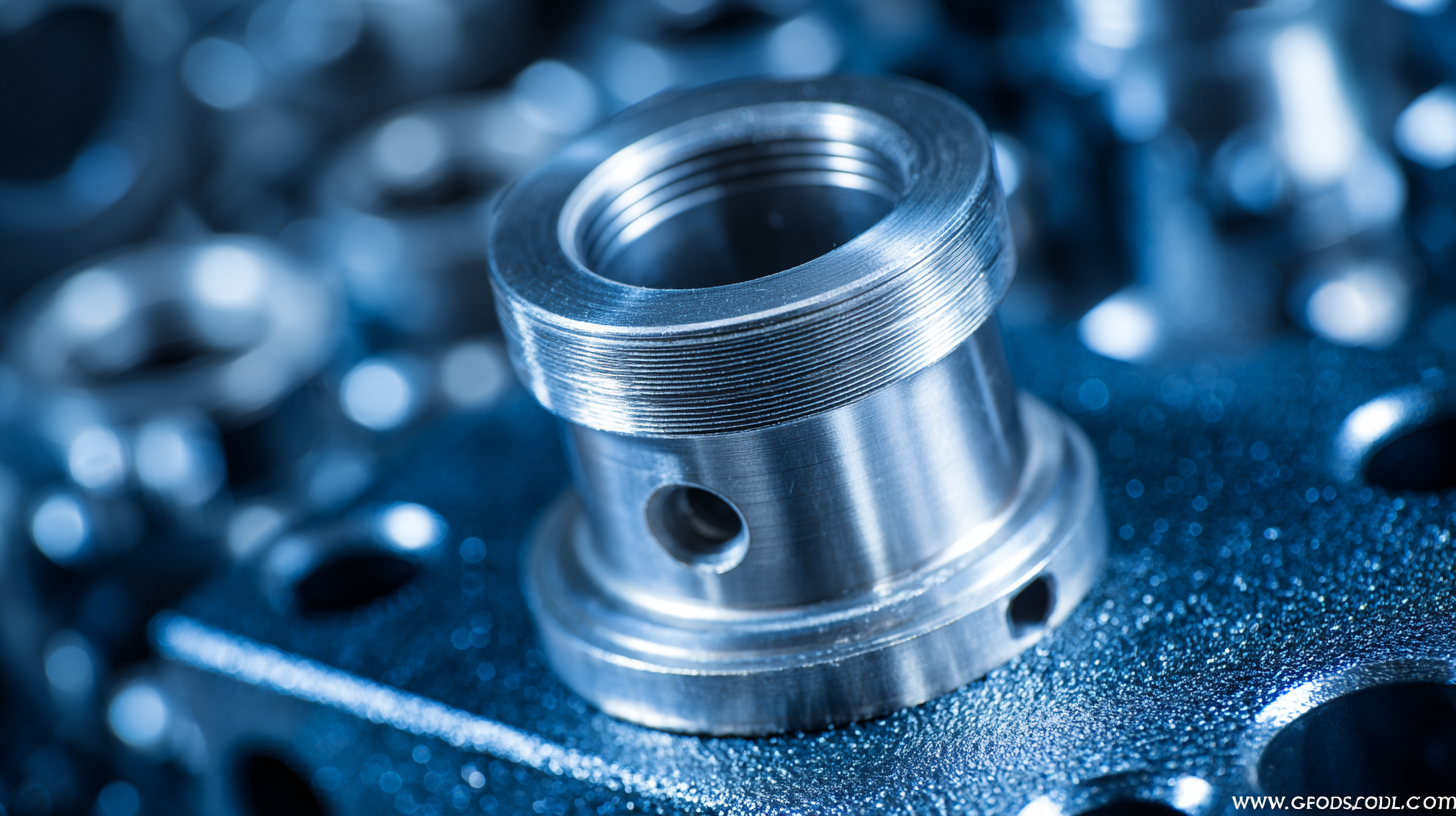

The future of machining parts manufacturing is rapidly evolving under the influence of emerging technologies that prioritize sustainability and efficiency. According to a recent review on sustainable machining, advancements in technology are significantly reducing environmental impacts associated with traditional cutting methods. These innovations include the implementation of eco-friendly cutting fluids and enhanced waste management practices, which are critical for minimizing the carbon footprint of machining operations. The 2025 Manufacturing Industry Outlook emphasizes that manufacturers are increasingly investing in digital infrastructures, which are expected to boost innovation and address the ongoing skills gap in the industry.

Moreover, the integration of artificial intelligence (AI) and robotics is revolutionizing the machining landscape by enhancing precision and automating repetitive tasks. The adoption of 3D printing technologies is particularly noteworthy, as it not only reduces material waste but also streamlines the production process, making it a more sustainable alternative to conventional manufacturing. As new technologies like additive manufacturing, CNC machining, and laser applications gain traction, they are setting new standards in the aerospace and defense sectors. These trends highlight the transformative potential of next-generation technologies, reshaping the future of machining parts manufacturing in ways that align with both operational efficiency and environmental responsibility.

Sustainability Trends Impacting Machining Parts Production Standards

As we move towards 2025, the machining parts industry is increasingly influenced by sustainability trends that are reshaping production standards globally. Companies are prioritizing ecological methods to enhance manufacturing processes, focusing on reducing pollution levels from coolants and emulsions. This shift is not only responding to regulatory pressures but is also aligning with the growing consumer demand for environmentally friendly products.

Incorporating automation and artificial intelligence is becoming crucial in this transformation. It allows for optimized machining processes that minimize waste and improve energy efficiency. As digitization continues to permeate the manufacturing sector, companies must embrace these technologies to meet sustainability targets while maintaining competitiveness.

Tips for Manufacturers:

- Invest in research to adopt cleaner technologies, reducing reliance on harmful coolants.

- Implement AI-driven solutions to monitor and optimize energy usage in real-time.

- Engage in multi-criteria decision-making processes to select machinery that balances performance with sustainability goals.

Regional Market Insights: Growth Opportunities in Machining Parts Sector

The machining parts sector is witnessing a transformative shift, driven by technological advancements and regional growth opportunities. In 2025, markets across different regions are expected to capitalize on innovations in machine control systems, which have shown a significant growth trajectory, projected to rise from $5.64 billion in 2023 to $9.20 billion shortly thereafter. This growth trend reflects a heightened demand for precision engineering and manufacturing efficiency, as industries increasingly embrace digital transformation and automation.

Regions with robust manufacturing bases, particularly in Asia-Pacific and North America, are set to experience significant advancements in the machine tools market, which is anticipated to reach a staggering $105.11 billion by 2032. Alongside this, niche markets such as record cleaning machines and plasma cutting technologies are also expanding, highlighting the diverse range of opportunities for stakeholders within the machining parts sector. As manufacturers prioritize their digital infrastructures to innovate and address the skills gap, the landscape for machining parts is poised for dynamic evolution leading into 2025 and beyond.

Future Skills: Workforce Adaptation for Advanced Machining Techniques

As the demand for advanced machining techniques grows, the workforce must be prepared to adapt to new technologies and practices. Future skills will be pivotal in ensuring that professionals are equipped to handle sophisticated machinery and processes. Embracing continuous education and training programs will be essential for workers looking to stay relevant in this evolving landscape. Companies should encourage a culture of learning, where employees feel empowered to enhance their skills through workshops and online courses, particularly in automation and data analysis.

Another critical area for adaptation is the integration of digital tools in machining processes. Skills related to programming CNC machines and utilizing CAD/CAM software will become increasingly valuable. To remain competitive, professionals should seek out certifications in these technologies. It’s also important to develop soft skills, such as problem-solving and critical thinking, to complement technical expertise, ensuring a well-rounded approach to advanced machining tasks.

Tips: Regularly participating in industry seminars and networking events can provide insights into emerging trends and technologies. Additionally, hands-on experience with new machinery can significantly enhance one's capabilities and confidence in using advanced techniques. Prioritizing collaboration among teams can also foster innovation and knowledge sharing, further driving the adaptation process.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.