Unleashing Global Manufacturing Power: Discover the Best Small CNC Milling Machines from China

In the rapidly evolving landscape of global manufacturing, the demand for precision and efficiency is more critical than ever. According to a recent report by MarketsandMarkets, the CNC machine market is projected to grow from $56.38 billion in 2020 to $81.74 billion by 2025, highlighting an increasing reliance on advanced machining processes.

In the rapidly evolving landscape of global manufacturing, the demand for precision and efficiency is more critical than ever. According to a recent report by MarketsandMarkets, the CNC machine market is projected to grow from $56.38 billion in 2020 to $81.74 billion by 2025, highlighting an increasing reliance on advanced machining processes.

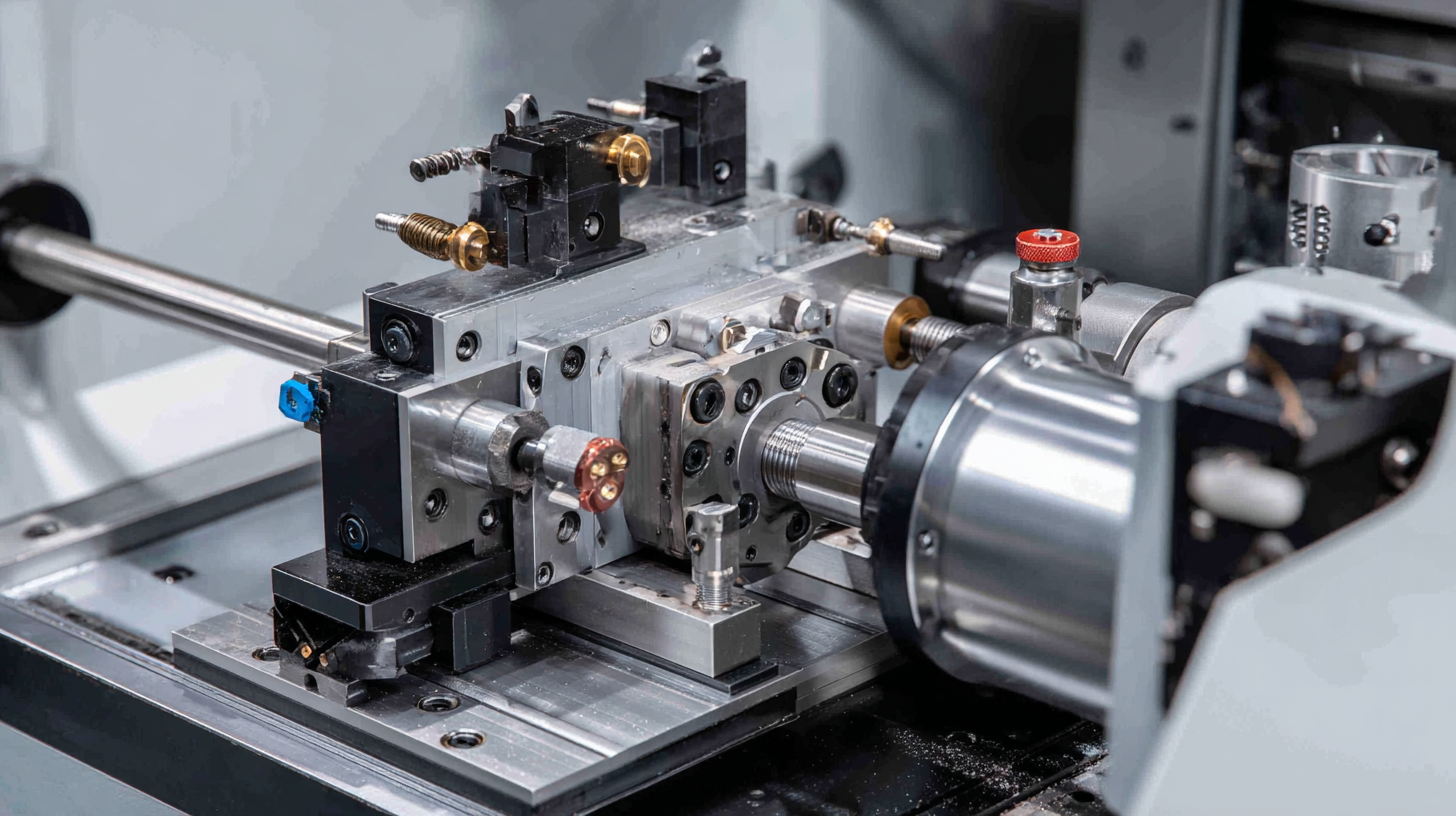

Among these, the small CNC milling machine stands out as a vital asset for both small-scale operations and larger manufacturers seeking to optimize production capabilities while minimizing costs. These compact and versatile machines enable manufacturers to produce intricate parts with high accuracy, thus making them an indispensable tool in various industries, from aerospace to medical device manufacturing.

As we delve deeper into the benefits of small CNC milling machines from China, it becomes evident that their contribution to enhancing productivity and cost-effectiveness can significantly impact the future of global manufacturing.

The Rise of CNC Milling Machines in Global Manufacturing Landscape

The rise of CNC milling machines marks a significant transformation in the global manufacturing landscape. As we move towards a more automated future, the demand for precision and efficiency in production processes is driving the growth of CNC technology. By 2024, the global CNC machine market is projected to reach $77 billion, highlighting the increasing reliance on advanced machinery to enhance production capabilities. This trend is not only reshaping manufacturing practices but is also contributing to the overall expansion of the milling machines market, set to surpass $13 billion by 2033.

China, a major player in this sector, has become synonymous with innovation in CNC milling technology. Small CNC milling machines from China are gaining traction for their affordability and sophisticated capabilities, allowing businesses of all sizes to capitalize on cutting-edge manufacturing solutions. As industries worldwide strive for competitive advantage, the integration of CNC milling machines is pivotal in optimizing workflows and improving product quality, ensuring that companies remain agile in a rapidly evolving market. The push towards enhanced manufacturing automation reflects a broader commitment to meeting the intricate demands of today's global economy.

Key Features to Look for in Small CNC Milling Machines

When exploring the world of small CNC milling machines, it's essential to understand the key features that can significantly influence performance and efficiency. One important aspect is the machine's axis type. Machines come in various configurations, including 3-axis, 4-axis, and even more sophisticated multi-axis options. A 3-axis machine is often sufficient for basic tasks, but for more complex shapes and angles, a 4-axis or multi-axis milling machine can offer greater versatility and precision.

Another crucial feature to consider is the type of milling process supported by the machine. Options like vertical milling machines and horizontal milling machines cater to different manufacturing needs. Vertical milling machines are typically used for simpler operations, while horizontal machines can handle heavier cuts and larger workpieces, enabling manufacturers to tackle a wider range of projects. Additionally, factors such as spindle speed, tool change capabilities, and the overall build quality play a vital role in determining the machine's effectiveness and reliability. Investing in a small CNC milling machine with these key features can elevate productivity and help unlock the potential of global manufacturing.

Global Small CNC Milling Machines Market Overview

The chart above illustrates the key features and their respective ratings for small CNC milling machines in the global market. Each feature has been rated on a scale from 1 to 10, indicating their importance and performance level.

Comparative Analysis of Leading Small CNC Milling Machine Brands from China

In the rapidly evolving landscape of global manufacturing, small CNC milling machines from China have emerged as key players, providing innovative solutions for various industries. A recent report by MarketsandMarkets indicates that the CNC machining market is expected to grow from $73 billion in 2021 to $100 billion by 2026, highlighting the increasing demand for efficient manufacturing tools. Among the leading brands, companies such as Tormach, TAIG, and HUISEN stand out for their performance and affordability. Their small CNC milling machines are designed to maximize productivity while minimizing the space and investment required, making them ideal for small to medium-sized enterprises.

Tip: When selecting a small CNC milling machine, consider factors such as spindle speed, cutting capabilities, and the availability of customer support. These elements can greatly affect the efficiency of your operations and long-term satisfaction with the equipment.

Additionally, the technical advancements in these machines have led to improved precision and reliability. According to a study by Grand View Research, the demand for CNC machines is also driven by the growing trend of automation in manufacturing processes. Understanding the specifications and comparing different brands can help businesses make informed decisions.

Tip: Always review user testimonials and case studies to gain insights into how various brands perform in real-world applications, which is crucial for making the right investment in CNC technology.

Unleashing Global Manufacturing Power: Discover the Best Small CNC Milling Machines from China

| Model | Working Area (mm) | Spindle Speed (RPM) | Tool Holder Type | Weight (kg) | Price Range (USD) |

|---|---|---|---|---|---|

| CNC Model A | 600 x 400 x 400 | 24000 | ER20 | 150 | 2000 - 2500 |

| CNC Model B | 800 x 500 x 500 | 20000 | BT30 | 180 | 2500 - 3000 |

| CNC Model C | 1000 x 600 x 600 | 18000 | ER16 | 200 | 3000 - 3500 |

| CNC Model D | 500 x 300 x 300 | 22000 | ER25 | 120 | 1500 - 2000 |

Cost-Effectiveness and ROI of Small CNC Milling Machines in Manufacturing

In today’s competitive manufacturing landscape, small CNC milling machines from China are gaining traction for their cost-effectiveness and impressive return on investment (ROI). According to a report by Technavio, the global CNC milling machine market is expected to grow by nearly $2.3 billion from 2021 to 2025, with small CNC machines driving a significant portion of this growth. Their affordability and versatility make them ideal for small to medium enterprises looking to optimize production without incurring hefty expenses.

The ROI for small CNC milling machines is enhanced by their capabilities to produce high-precision parts at a fraction of the cost of larger machines. A study conducted by the Manufacturing Institute reveals that businesses leveraging CNC milling technology can see productivity gains of up to 30%. Additionally, the lower initial investment costs allow startups and small manufacturers to adopt advanced technology, making high-volume production feasible. With reduced manpower requirements and machine downtime, these small CNC mills not only cut costs but also increase throughput, establishing a robust competitive edge in today’s manufacturing sector.

Future Trends: Innovations Shaping the Small CNC Milling Machine Market

The small CNC milling machine market is experiencing transformative innovations that are reshaping how manufacturers approach precision engineering. With advancements in technology, these machines are becoming more accessible and efficient, catering to a broader range of industries. Key trends include the integration of smart technology, automation, and enhanced user interfaces, enabling operators to achieve high levels of accuracy with minimal effort. As manufacturers increasingly seek solutions that maximize productivity and reduce downtime, the demand for small CNC milling machines with cutting-edge features continues to grow.

Tips for selecting the right small CNC milling machine include evaluating the specific requirements of your projects and considering the machine's compatibility with various materials. Additionally, prioritize machines that offer robust software support and user-friendly operation. Investing in machines that incorporate IoT technology can also provide real-time monitoring and analytics, driving efficiency in production processes.

Furthermore, sustainability is becoming a paramount focus in the CNC milling sector. Manufacturers are now looking for machines designed to minimize waste and energy consumption while maintaining performance. Keep an eye on innovations that promote environmentally-friendly practices, as these are expected to gain traction in the marketplace, influencing purchasing decisions and shaping the future of small CNC milling machines.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.