The Future of Manufacturing CNC Metal Parts A Deep Dive into Industry Trends and Innovations

As the manufacturing landscape evolves, the significance of CNC metal parts continues to grow, driven by advancements in technology and shifting industry demands. According to a recent report by MarketsandMarkets, the global CNC machining market is projected to reach USD 117.51 billion by 2026, expanding at a CAGR of 7.5% from 2021. This growth is fueled by the increasing adoption of automation and Industry 4.0 practices, which enhance efficiency and precision in production processes. Furthermore, the drive towards lightweight materials and customizable manufacturing solutions underscores the pivotal role CNC metal parts play in various sectors, including aerospace, automotive, and medical industries. As companies strive for enhanced productivity and competitive advantage, understanding the emerging trends and innovations in CNC metal parts manufacturing becomes crucial for stakeholders aiming to navigate the complexities of the future market.

Emerging Technologies Revolutionizing CNC Metal Parts Manufacturing

The landscape of CNC metal parts manufacturing is rapidly evolving, significantly influenced by emerging technologies such as artificial intelligence (AI) and 3D printing. AI applications in additive manufacturing are gaining traction, enabling more efficient processes and enhanced quality control across the manufacturing ecosystem. Experts note that AI can revolutionize CNC programming by automating complex tasks and optimizing production workflows, thereby reducing downtime and material waste.

Moreover, innovations like sustainable micro-plasma 3D printing are paving the way for environmentally friendly practices in metal additive manufacturing. This new technology not only consumes less energy but also minimizes harmful emissions, aligning with the global push towards sustainable manufacturing solutions. Companies are increasingly integrating these advanced technologies, such as IoT and digitalization, to enhance operations and drive competitive advantages. The ongoing transformation is setting a new standard for quality, efficiency, and sustainability in the CNC machining industry.

Sustainability and Eco-Friendly Practices in CNC Manufacturing

As the manufacturing industry evolves, sustainability and eco-friendly practices are becoming increasingly important in CNC metal parts production. According to a report by McKinsey, manufacturers that adopt sustainable practices can improve their operational efficiency by up to 20%. This shift not only helps in reducing waste but also aligns with the growing demand from consumers who prefer environmentally responsible products. The integration of eco-friendly materials and processes, such as the use of recycled aluminum and energy-efficient machining practices, is paving the way for a more sustainable future in CNC manufacturing.

Moreover, advancements in technology, such as AI and machine learning, enable manufacturers to optimize their production processes, further minimizing their environmental impact. A study by the Massachusetts Institute of Technology highlights that implementing intelligent manufacturing systems can lead to a 15% reduction in carbon emissions. Companies are now focusing on developing closed-loop manufacturing systems that recycle materials and reduce resource consumption, showcasing a significant shift towards sustainable manufacturing practices in the CNC sector.

The trend towards green manufacturing is not just a regulatory response but a strategic initiative that offers long-term benefits for businesses and the planet alike.

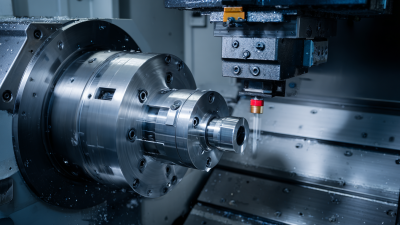

The Impact of Automation and AI on CNC Processes and Efficiency

The evolution of manufacturing, particularly in the realm of CNC (Computer Numerical Control) machining, is significantly influenced by the integration of automation and artificial intelligence (AI). These advancements not only enhance operational efficiency but also refine the accuracy and consistency of metal parts produced. Automation streamlines workflows, reducing human error and increasing production rates. AI technologies, in conjunction with machine learning algorithms, allow for predictive maintenance and real-time optimization of processes, ensuring manufacturers can swiftly adapt to changing demands.

**Tips for Implementation:**

1. Invest in training programs that equip your workforce with the necessary skills to harness automation and AI tools effectively.

2. Start small by integrating AI into select production segments to monitor performance and gradually expand based on successful outcomes.

Furthermore, the use of AI-driven data analytics provides manufacturers with valuable insights into machinery performance and operational bottlenecks. By analyzing vast amounts of data, organizations can identify areas for improvement and implement significant upgrades, leading to reduced downtime and enhanced productivity. As the manufacturing landscape continues to evolve, embracing these technologies will be essential for staying competitive and meeting the growing demands of the market.

**Tips for Monitoring Progress:**

1. Regularly review performance metrics to gauge the impact of automation and AI on production efficiency.

2. Utilize software tools that offer real-time data visualization to track progress and make informed decisions.

The Future of Manufacturing CNC Metal Parts: Trends in Automation and AI

This chart illustrates the trends in automation and AI's impact on CNC metal manufacturing processes. The data reflects the increase in efficiency and cost-effectiveness resulting from advancements in technology.

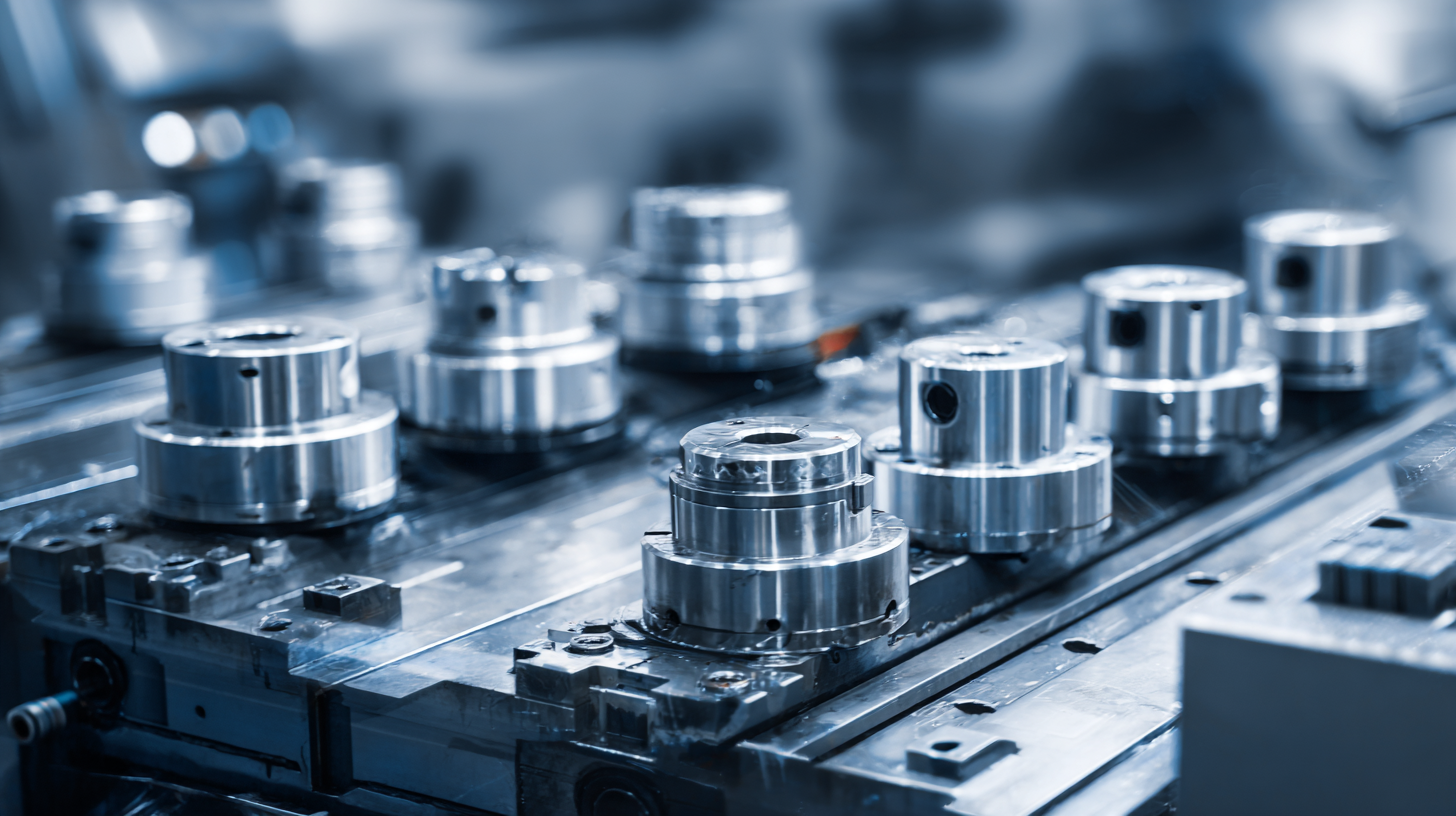

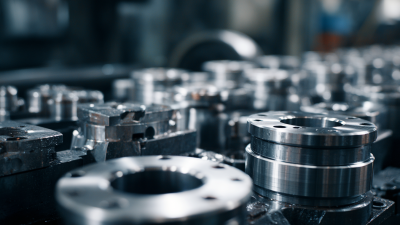

Trends in Material Selection and Engineering for CNC Metal Parts

The evolution of material selection and engineering in CNC metal parts is significantly shaping the future of manufacturing. With advancements in technology, manufacturers are increasingly opting for lightweight and high-strength materials such as titanium alloys and advanced composites. According to a report by MarketsandMarkets, the global metal 3D printing market is expected to grow from $1.4 billion in 2022 to $4.4 billion by 2027, highlighting a rising trend in material innovation and its application in CNC machining. These innovations not only elevate the performance of parts but also enhance design flexibility, enabling complex geometries which were previously unattainable.

Moreover, the integration of smart materials, including shape-memory alloys and self-healing materials, is on the rise. These materials adapt to environmental changes and provide enhanced durability in demanding applications. A study by Deloitte emphasizes that incorporating smart materials can result in a 20% reduction in manufacturing costs, along with extended lifecycle benefits. As industries push towards sustainability, eco-friendly material options are being prioritized, fostering a shift towards recycled and bio-based metals, solidifying the future of CNC metal parts as both innovative and responsible.

Market Demands and Customization in the Future of CNC Manufacturing

The future of CNC manufacturing is poised for significant growth, driven by increasing market demands and the rise of customization. According to a recent market research study, the global plate rolling machine market is expected to reach USD 638.37 million by 2034, growing at a CAGR of 5.1%. This trend reflects a broader shift in the manufacturing landscape, where tailored solutions become essential for meeting unique customer requirements.

Parallel to this, the CNC plasma cutting machines market is projected to grow from USD 707.5 million in 2025 to an impressive USD 1,163.5 million by 2035. The expansion of the milling machine market further underscores this movement, with an expected increase to USD 116,722.7 million by 2035, fueled by advancements in CNC technology and smart automation. As manufacturers adapt to these evolving demands, the industry is likely to see greater emphasis on precision and versatility in their offerings, facilitating a more customized approach to production.

Related Posts

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Exploring the Top Examples of Large CNC Machines for Global Buyers

-

Understanding Common Issues in Precision CNC Machining Processes

-

The Future of Precision Engineering: Innovations in Best CNC Parts Production

-

Mastering the Art of Selecting the Best Machining Parts for Your Global Supply Chain

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.