Exploring the Evolution of CNC Machine Working: Key Innovations and Their Impact on Manufacturing Efficiency

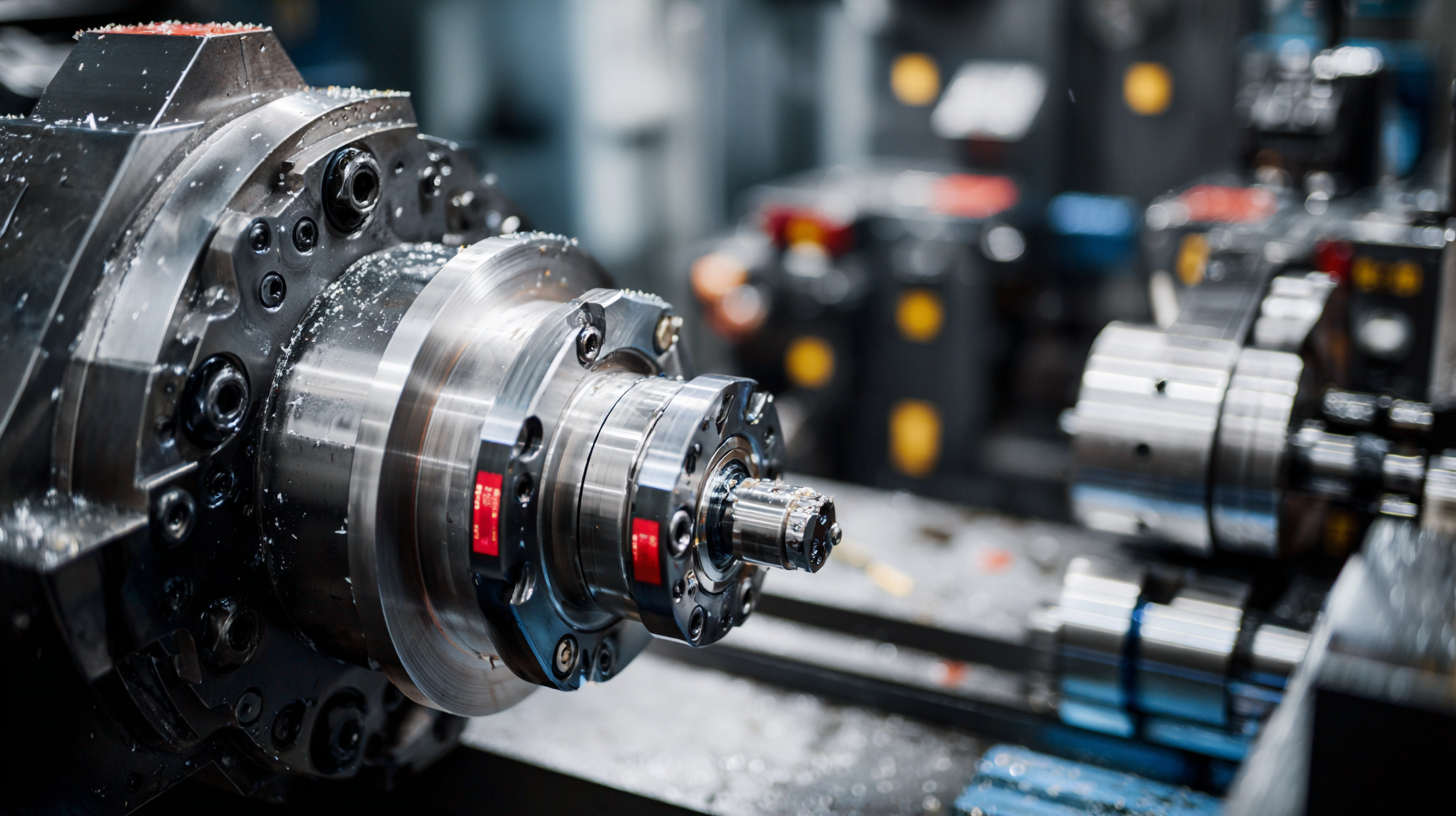

The evolution of CNC machine working has fundamentally transformed the landscape of modern manufacturing, driving unprecedented efficiency and precision across various industries. As technology continues to advance, key innovations in CNC machining have emerged, reshaping production processes and enhancing capabilities.

From the introduction of computer numerical control in the late 20th century to the integration of advanced software, robotics, and automation, each development has contributed to a remarkable increase in manufacturing output and quality. In this exploration, we will delve into the pivotal innovations that have shaped CNC machine working, analyzing their impact on workflow optimization, cost reduction, and product consistency.

By understanding these advancements, manufacturers can better appreciate how CNC technology drives competitiveness in today's fast-paced market.

The Historical Development of CNC Machines: From Manual to Automation

The evolution of CNC (Computer Numerical Control) machines has significantly transformed the manufacturing landscape, transitioning from traditional manual operations to highly automated processes. This shift has been fueled by a growing demand for precision and efficiency in metal forming processes. As industries strive to meet market demand, the incorporation of automation in manufacturing has become increasingly prevalent, allowing for greater production capabilities while minimizing human error.

The rise of robotics technology further complements the automation trend within CNC machining. With advancements in automation, machine design and operation have been revolutionized, leading to enhanced productivity and streamlined workflows. The market for CNC machines is projected to experience substantial growth, with estimates predicting an increase from $101.22 billion in 2025 to $195.59 billion by 2032, demonstrating a compound annual growth rate (CAGR) of 9.9%. This significant expansion indicates a robust future for CNC machinery, underscoring its vital role in evolving manufacturing processes and meeting the demands of a fast-paced market.

Key Technological Innovations in CNC Machinery Over the Decades

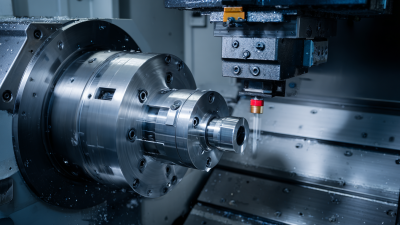

The landscape of CNC machinery has undergone significant transformations over the decades, driven by key technological innovations that have reshaped manufacturing processes. Modern CNC machines leverage advanced digital control technologies, enhancing precision and efficiency. For instance, innovations such as SINUMERIK ONE have marked a new era of digital controls, elevating the capabilities of CNC machines to unprecedented levels. This evolution is not just confined to larger machinery; developments in desktop CNC machines reflect a growing trend that democratizes access to high-quality manufacturing tools.

As the CNC market continues to expand, the introduction of innovative solutions is critical. From enhanced user interfaces to integration with IoT, these advancements are set to redefine how manufacturers approach production. Staying abreast of these trends will empower businesses to optimize workflows and reduce downtime, ultimately contributing to a more efficient manufacturing ecosystem.

The Role of Software Advancements in Enhancing CNC Machine Performance

The advancements in software technology are drastically reshaping the performance of CNC machines, enhancing their operational efficiency and capabilities. According to a market analysis, the travel column CNC machining center market was valued at $245 million in 2022, with projections indicating it will escalate to $398 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.5% from 2024 to 2030. This growth can be largely attributed to the integration of sophisticated software solutions that streamline programming processes, optimize machining paths, and improve user interfaces.

Modern CNC machines now incorporate advanced software that extends beyond basic G-code programming, embracing features such as real-time monitoring and predictive maintenance. These innovations not only improve the precision and speed of machining tasks but also reduce downtime and waste, driving significant improvements in manufacturing efficiency. As companies increasingly adopt these technological advancements, they position themselves to meet the rising demands of the market while maintaining a competitive edge.

Impact of CNC Technology on Precision and Production Speed in Manufacturing

The impact of CNC technology on precision and production speed in manufacturing cannot be overstated. As industries increasingly rely on lightweight materials such as carbon fiber and titanium, CNC machining has emerged as a critical technique. It allows for the creation of complex and precise parts that are essential in sectors ranging from aerospace to automotive. The evolution of CNC capabilities has led to significant enhancements in both the accuracy of parts and the overall production speed, enabling manufacturers to meet the growing demand for high-performance structures efficiently.

Modern innovations in CNC systems, particularly the integration of robotic automation, further amplify these benefits. This automation facilitates quicker tool changes and improves material handling, resulting in a more seamless manufacturing process. As highlighted by recent developments in tube cutting technology, attention to detail in precision engineering continues to play a vital role in product success. With CNC machining evolving rapidly alongside digital manufacturing technologies, manufacturers are set to experience substantial productivity gains, reshaping the landscape of precision production for years to come.

Future Trends in CNC Machine Technology and Their Potential Impact on Industry

The future of CNC machine technology is poised for significant transformation driven by emerging trends in digitalization, artificial intelligence (AI), and the Internet of Things (IoT). As these technologies continue to evolve, they promise to enhance manufacturing efficiency through improved automation and data analytics. For instance, AI can facilitate predictive maintenance, reducing downtime and optimizing operational workflows. Meanwhile, IoT enables real-time monitoring of CNC machines, allowing manufacturers to make informed decisions that streamline processes and minimize waste.

Moreover, the integration of Industry 4.0 principles is catalyzing a shift towards smarter manufacturing systems. Companies are increasingly adopting advanced CNC machinery that leverages connectivity and data sharing, ultimately leading to enhanced precision in production. In sectors like rice milling, technological advancements have demonstrated significant improvements in efficiency and sustainability. These innovations are setting the stage for a future where CNC machines not only meet the demands of modern manufacturing but also align with sustainable practices. Thus, the landscape of CNC technology is evolving rapidly, with profound implications for the industry's efficiency and competitiveness.

Exploring the Evolution of CNC Machine Working: Key Innovations and Their Impact on Manufacturing Efficiency - Future Trends in CNC Machine Technology and Their Potential Impact on Industry

| Dimension | 2015 | 2020 | 2023 | Future Trend (2025) |

|---|---|---|---|---|

| CNC Machine Usage (Units) | 150,000 | 220,000 | 300,000 | 400,000 |

| Average Cutting Speed (m/min) | 25 | 40 | 60 | 80 |

| Manufacturing Efficiency (%) | 65 | 75 | 85 | 90 |

| Market Growth Rate (%) | 6 | 8 | 10 | 12 |

| Total Industry Revenue (Billion $) | 25 | 35 | 50 | 70 |

Related Posts

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Innovative Solutions for Your Home CNC Machine Investment

-

Understanding Common Issues in Precision CNC Machining Processes

-

10 Essential Tips for Optimizing CNC Machine Working Efficiency in Your Factory

-

Addressing High Precision Machining Challenges: Common Issues and Solutions

-

Understanding CNC Machine Working Principles and Their Applications

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.