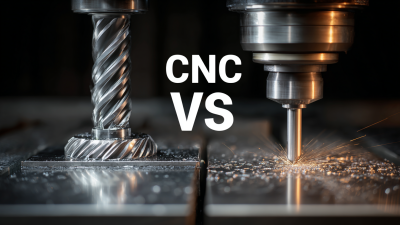

10 Essential Tips for Optimizing CNC Machine Working Efficiency in Your Factory

In today's fast-paced manufacturing landscape, optimizing CNC machine working efficiency is not just a goal but a necessity for staying competitive. According to a report by the International Federation of Robotics, the global demand for CNC machines is projected to grow by over 14% in the next five years, highlighting the critical role these machines play in modern production processes. However, many manufacturers still struggle with maximizing the operational capacity of their CNC equipment, leading to decreased productivity and increased costs. By implementing effective strategies, businesses can enhance their CNC machine working efficiency, ultimately resulting in reduced lead times, improved product quality, and higher profitability. This blog presents ten essential tips that can transform your factory operations and ensure your CNC machines are running at peak performance.

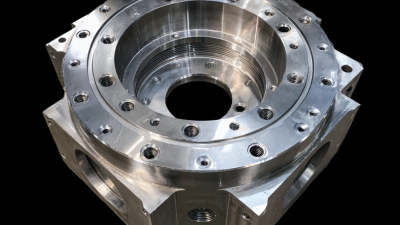

Maximizing Setup Precision for Improved CNC Performance

When it comes to optimizing CNC machine working efficiency, maximizing setup precision is crucial for achieving improved performance. Studies show that precision setup can reduce machining errors by up to 30%, leading to higher quality production and lower material waste. The adoption of advanced technologies, such as five-axis VMCs, enhances the ability to machine complex parts with tight tolerances, which is becoming increasingly important in competitive manufacturing environments.

For instance, advanced equipment features, like those found in modern VMCs, provide superior speed and rigidity, which are essential for handling demanding applications. By ensuring accurate setups through meticulous calibration and tool selection, manufacturers can significantly improve their throughput and reduce cycle times. According to industry reports, factories that implement rigorous setup procedures and invest in high-quality machinery see a 20% increase in overall operational efficiency. This trend reflects the growing need for precision in manufacturing processes to meet the rising demands of technologically sophisticated products.

Implementing Routine Maintenance to Minimize Downtime

Regular maintenance is crucial for ensuring CNC machines operate at peak efficiency. Implementing a routine maintenance schedule can significantly minimize downtime, allowing for smoother operations in your factory. Scheduling preventative checks, such as lubrication, calibration, and part replacement, helps to catch potential issues before they escalate into costly repairs. By taking a proactive approach, you can maintain consistent production levels and enhance the overall lifespan of your equipment.

Moreover, training your staff to recognize warning signs of wear and tear plays a vital role in maintenance. Educated operators can identify minor problems early, enabling timely interventions that prevent unexpected breakdowns. Empowering your team with knowledge encourages a culture of accountability and vigilance, ensuring that each machine is monitored effectively. This not only reduces the frequency of machine failures but also drives a more efficient and productive work environment.

Utilizing Advanced Software for Enhanced CNC Programming

Utilizng advanced software for CNC programming is crucial for enhancing productivity and workflow in any manufacturing environment. Incorporating digital manufacturing solutions allows job shops to achieve seamless end-to-end connectivity, significantly reducing lead times and optimizing operations without the need for physical expansion. These innovations enable manufacturers to refine metalcutting processes, ensuring that machine operators and engineers leverage the latest capabilities to maximize efficiency.

The rise of AI in CNC programming is shaping a new era in precision manufacturing. By adopting predictive maintenance and automated programming, manufacturers can proactively address potential issues, increasing uptime and operational reliability. Furthermore, advanced CAD/CAM options serve as powerful tools that can streamline workflows and enhance productivity, making it easier for facilities to meet the increasing demands of the market. Embracing these technologies is essential for staying competitive in the rapidly evolving landscape of CNC machining.

Analyzing Tool Life to Optimize Cutting Efficiency

When it comes to optimizing cutting efficiency in CNC machining, analyzing tool life plays a critical role. Understanding how long tools maintain their performance under specific conditions allows manufacturers to make informed decisions about tool selection and replacement. Regular monitoring of tool wear can help identify patterns that may indicate the need for adjustments in the machining process. Utilizing advanced monitoring systems can provide real-time data, enabling quicker responses to tool degradation and ultimately improving production efficiency.

One essential tip is to implement a proactive maintenance schedule. Scheduled inspections and replacements based on tool wear monitoring will ensure that tools are functioning at their optimal levels longer, reducing unexpected downtime. Additionally, using cutting tools that are made for specific materials and applications can significantly prolong tool life, improving overall efficiency and minimizing waste.

Another crucial point is to analyze cutting parameters meticulously. Adjusting feed rates and spindle speeds according to the tool life data can maximize performance. For instance, small adjustments in cutting speed can yield significant improvements in tool durability. By continually refining these parameters based on observed data, manufacturers can achieve a more efficient machining process that not only enhances tool life but also optimizes overall productivity.

10 Essential Tips for Optimizing CNC Machine Working Efficiency in Your Factory

| Tip Number | Tip | Expected Impact | Tool Life (Hours) | Cutting Efficiency (%) |

|---|---|---|---|---|

| 1 | Regular Machine Maintenance | Reduce Downtime | 200 | 90 |

| 2 | Optimize Tool Path | Increase Material Removal Rate | 150 | 85 |

| 3 | Use Quality Cutting Tools | Improved Precision | 250 | 92 |

| 4 | Monitor Tool Wear | Enhance Tool Life | 180 | 88 |

| 5 | Implement Effective Cooling | Reduce Heat Generation | 220 | 90 |

| 6 | Train Operators | Increase Efficiency | 170 | 87 |

| 7 | Schedule Jobs Effectively | Maximize Usage | 190 | 89 |

| 8 | Upgrade Software Regularly | Access Latest Features | 160 | 86 |

| 9 | Reduce Idle Time | Increase Production | 210 | 91 |

| 10 | Review Cutting Parameters | Optimize Performance | 200 | 93 |

Training Your Team for Better CNC Operation Skills

Training your team for better CNC operation skills is crucial for maximizing the efficiency of CNC machines in any manufacturing environment. According to a report by the Association for Manufacturing Technology, companies that invest in ongoing training programs can improve productivity by as much as 30%. This isn’t just about understanding the machinery; it involves comprehensively embracing the latest advancements in CNC technology, including automation and advanced programming techniques. By providing workers with the necessary skills, manufacturers can enhance precision, reduce errors, and minimize machine downtimes significantly.

Furthermore, a study by the National Institute of Standards and Technology indicates that skilled operators are more adept at troubleshooting issues that may arise during production, thus maintaining a smoother workflow. Implementing structured training modules—ranging from basic operational workshops to advanced problem-solving sessions—can empower your team and foster an environment of continuous improvement. With the right training, it’s possible to transform the workforce into an agile and highly skilled team capable of optimizing CNC operations, ultimately leading to increased profitability for the factory.

10 Essential Tips for Optimizing CNC Machine Working Efficiency

This chart illustrates the effectiveness of various training strategies implemented to improve CNC operation skills over a six-month period, demonstrating the enhancement in productivity and machine utilization.

Related Posts

-

Finding Top Quality Suppliers for the Best Metal CNC Machines

-

Exploring the Top Examples of Large CNC Machines for Global Buyers

-

Understanding CNC Machine Working Principles and Their Applications

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Global Quality Revolution in Best Large Part CNC Machining Made in China

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.