Understanding Common Issues in Precision CNC Machining Processes

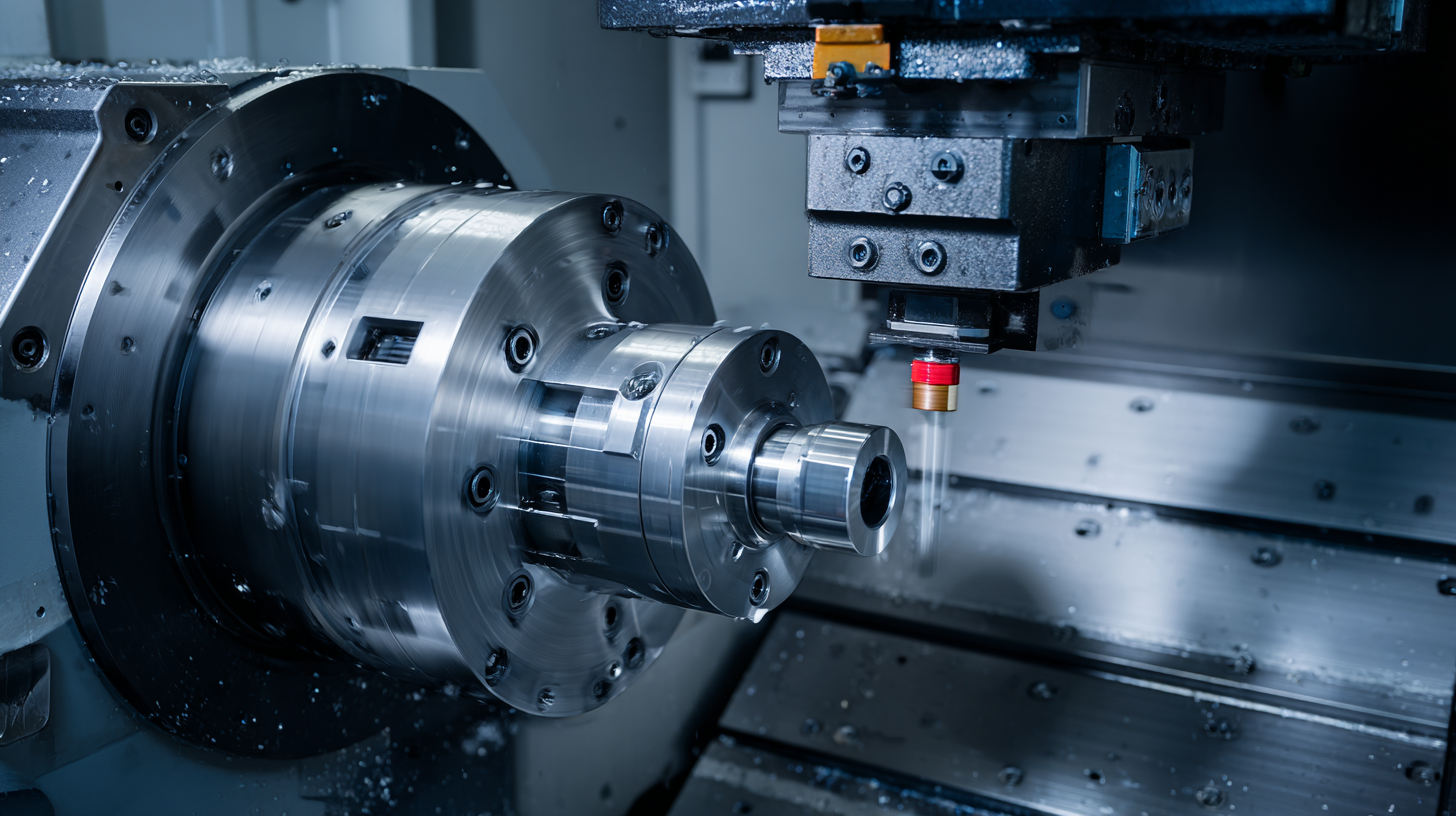

In the ever-evolving landscape of manufacturing, precision CNC machining has emerged as a cornerstone for achieving high-quality production standards across various industries. According to a recent report by MarketsandMarkets, the global CNC machining market is expected to reach $100 billion by 2025, driven by increased demand for precision parts in sectors such as aerospace, automotive, and medical devices. Despite its advantages, precision CNC machining processes are not devoid of challenges, including tool wear, machine calibration, and material inconsistencies. Addressing these common issues is crucial for manufacturers aiming to enhance efficiency and reduce production costs. This article will explore the top strategies for overcoming these obstacles and ensuring optimal precision CNC machining outcomes in today’s competitive environment.

Common Challenges in CNC Machining and Their Impact on Precision

Precision CNC machining is a highly advanced manufacturing process, yet it is not without its challenges. One of the most common issues encountered is tool wear, which can negatively impact the precision of the final product. As cutting tools gradually wear down, they may fail to maintain the desired specifications, leading to increased tolerances and potential defects. Regular monitoring and timely replacement of tools are crucial to mitigate this issue and ensure high-quality machined parts.

Another significant challenge is the setup and calibration of CNC machines. Inaccurate setups can lead to misalignment, resulting in poorly machined components. This misalignment often stems from insufficient calibration of the machines, which can be exacerbated by environmental factors such as temperature fluctuations. Addressing these problems requires meticulous attention to detail during the setup phase, as well as regular maintenance and inspections to maintain the operational integrity of CNC equipment. By overcoming these hurdles, manufacturers can enhance the accuracy and reliability of their precision CNC machining processes.

Common Challenges in CNC Machining and Their Impact on Precision

Identifying Root Causes of Precision Issues in CNC Processes

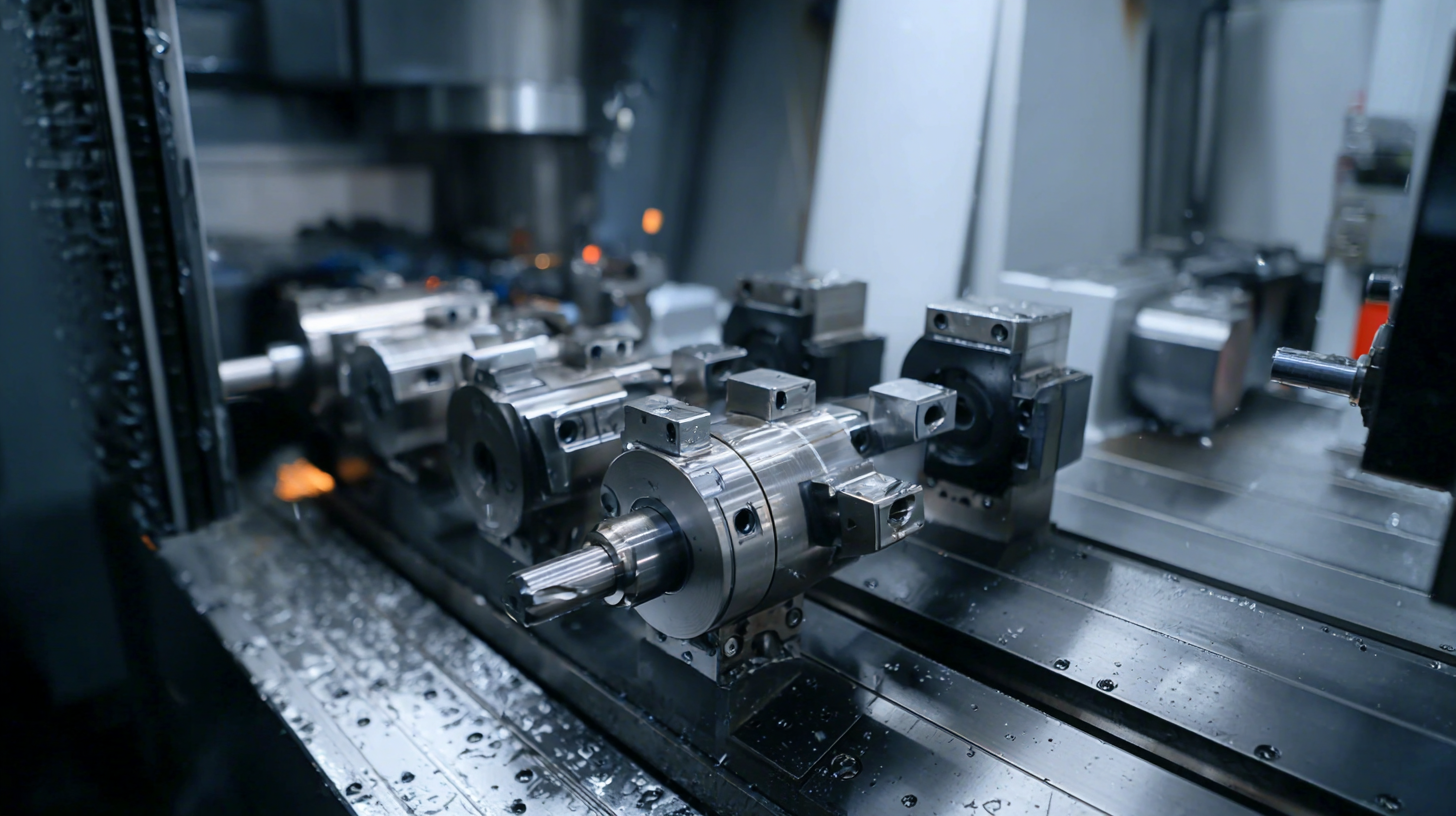

In precision CNC machining, identifying the root causes of precision issues is crucial for ensuring optimal performance and quality. Common problems often arise from several factors, including tool wear, machine calibration, and operator errors. When tools become dull or damaged, they fail to maintain the desired tolerances, leading to inconsistent results. Regular maintenance and timely tool replacement are essential to mitigate these issues and maintain production standards.

Another significant aspect is the machine calibration. CNC machines require precise adjustments to operate within specified tolerances. If a machine is not calibrated correctly, even minor discrepancies can result in substantial inaccuracies in the final product. Therefore, establishing a routine calibration schedule assists operators in detecting and addressing deviations promptly.

Additionally, operator proficiency plays a vital role in CNC machining precision. Unsurprisingly, human error can lead to incorrect settings or programming mistakes. Training programs that enhance operator skills and knowledge about the machinery can greatly reduce the likelihood of such errors. By focusing on these root causes, manufacturers can enhance the reliability and quality of their CNC machining processes.

Effective Solutions for Minimizing Tolerance Violations

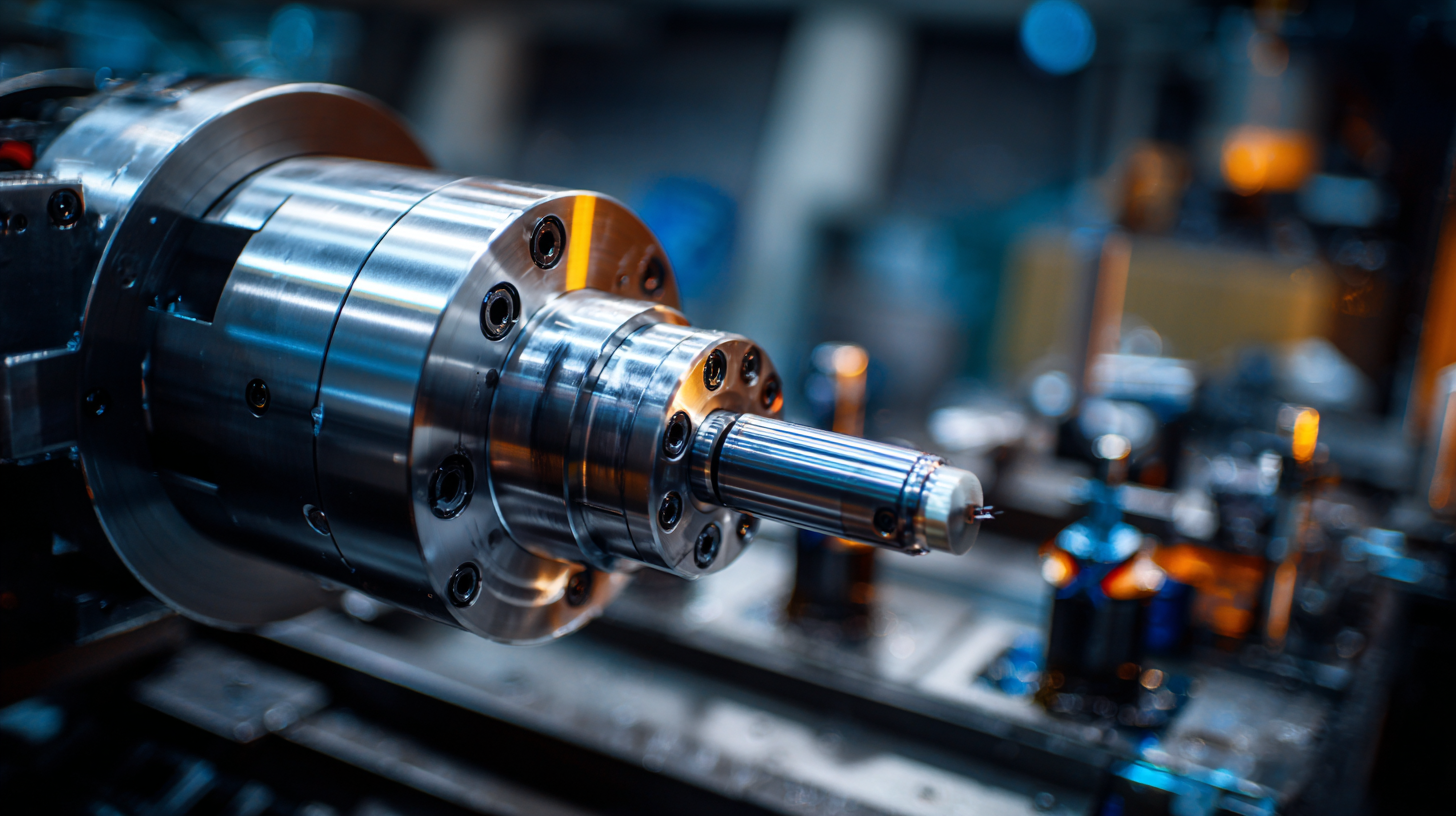

Precision CNC machining is a cornerstone of modern manufacturing, yet tolerance violations remain a persistent challenge. According to a report by the National Institute of Standards and Technology, nearly 20% of all manufacturing defects stem from insufficient tolerancing standards. These violations not only compromise product quality but can also lead to costly rework and delays. Therefore, understanding the root causes and implementing effective solutions is crucial for manufacturers aiming for operational excellence.

To minimize tolerance violations, manufacturers can prioritize regular equipment maintenance and calibration as part of their quality assurance process. A study published in the Journal of Manufacturing Science and Engineering highlighted that companies that invested in proactive maintenance saw a reduction in machining errors by up to 30%. Additionally, employing advanced software for simulation and tooling can help anticipate discrepancies, enabling operators to make real-time adjustments. By leveraging data from these sophisticated tools, CNC machining processes can achieve tighter tolerances, resulting in improved reliability and customer satisfaction.

Understanding Common Issues in Precision CNC Machining Processes - Effective Solutions for Minimizing Tolerance Violations

| Issue | Description | Causes | Solution |

|---|---|---|---|

| Tool Wear | Degradation of tool edge leading to poor surface finish and dimensional inaccuracies. | Inadequate lubrication, suboptimal feed rates, and prolonged tool usage. | Regular tool inspection and replacement, optimized cooling and lubrication. |

| Vibration | Uncontrolled movements that can affect part precision and surface quality. | Improper machine setup, workpiece rigidity issues, and tool balance. | Use of vibration dampeners and stabilizers, ensuring proper fixture setup. |

| Thermal Distortion | Changes in part dimensions caused by heat from machining. | High cutting speeds, excessive friction, and environmental temperature fluctuations. | Control machining parameters, use coolant effectively, and allow for post-machining cooling. |

| Dimensional Drift | Progressive deviation from specified dimensions over time. | Tool wear, machine misalignment, and inconsistent material properties. | Implement regular machine calibration, tool condition monitoring, and material quality checks. |

| Surface Finish | Poor finishing leading to rough surfaces and aesthetic issues. | Incorrect tooling, inadequate speeds, or incorrect feed rates. | Select appropriate tooling, optimize speeds and feeds for specific materials. |

Innovative Technologies Enhancing CNC Machining Accuracy

The integration of innovative technologies into precision CNC machining processes has revolutionized manufacturing across various industries. By 2025, advancements in digital manufacturing are projected to enhance productivity significantly, responding to the growing market demands driven by aging populations and the necessity for improved patient outcomes. According to industry forecasts, the global precision tool market is expected to expand from USD 231.78 billion in 2025 to approximately USD 346.38 billion by 2033, reflecting a remarkable CAGR. This growth illustrates the increasing reliance on precision machining to meet modern manufacturing challenges.

To further enhance CNC machining accuracy, manufacturers are now exploring automation, real-time data analytics, and advanced materials. Companies adopting these technologies not only improve their precision but also optimize their operational efficiency.

**Tip**: To stay competitive, consider investing in smart manufacturing solutions that leverage data-driven decision-making to improve product quality and reduce waste.

Additionally, embracing machine learning algorithms can enable predictive maintenance, reducing downtime and ensuring that machining processes maintain peak performance.

**Tip**: Regularly training your workforce on new technologies can maximize the benefits of these innovations, fostering a culture of continuous improvement in your CNC machining operations.

Best Practices for Quality Control in Precision Machining

Quality control is a crucial aspect of precision CNC machining processes, ensuring that finished products meet the exact specifications required by clients. To maintain high standards, it is essential to implement

best practices throughout the production cycle. One effective strategy is to adopt a systematic approach to measuring and monitoring critical dimensions and tolerances. This can be achieved through the use of advanced inspection tools, such as coordinate measuring machines (CMMs), which provide accurate readings and help identify any deviations from the desired specifications early in the process.

Quality control is a crucial aspect of precision CNC machining processes, ensuring that finished products meet the exact specifications required by clients. To maintain high standards, it is essential to implement

best practices throughout the production cycle. One effective strategy is to adopt a systematic approach to measuring and monitoring critical dimensions and tolerances. This can be achieved through the use of advanced inspection tools, such as coordinate measuring machines (CMMs), which provide accurate readings and help identify any deviations from the desired specifications early in the process.

Another important practice is to establish a robust feedback loop between the machining operators and quality control personnel. This collaboration allows for immediate response to any quality issues that may arise, facilitating real-time adjustments to machining parameters. Training operators in quality awareness enhances their ability to detect potential problems beforehand, fostering a culture of continuous improvement. Furthermore, maintaining detailed documentation of quality control measures and results can assist in identifying trends and implementing preventative measures, ultimately leading to more reliable machining processes and satisfied customers.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.