10 Expert CNC Milling Tips for Maximizing Efficiency and Precision in Production

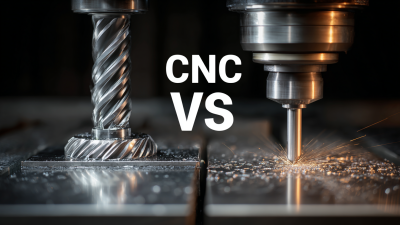

CNC milling has revolutionized the manufacturing landscape, providing unparalleled precision and efficiency in the production process. As industries increasingly rely on automated technologies to enhance their operations, mastering the art of CNC milling becomes imperative for engineers and machinists alike. In this article, we will explore ten expert tips designed to optimize your CNC milling practices, ensuring that you achieve not only higher productivity but also remarkable precision in your output.

Whether you are a seasoned professional or new to CNC milling, understanding the nuances of the process can significantly impact your results. From selecting the right tooling and materials to optimizing machine settings and implementing efficient workflows, each aspect plays a vital role in maximizing both speed and accuracy. By adopting these expert strategies, you will be well-equipped to navigate the complexities of CNC milling and elevate your production capabilities to new heights. Join us as we delve into essential tips that will transform your approach and help you achieve excellence in CNC milling.

Maximizing Tool Life: Strategies for Extended Performance in CNC Milling

Maximizing tool life is a critical goal in CNC milling, as it directly impacts production efficiency and overall costs. According to a recent industry report by the National Institute of Standards and Technology (NIST), improper tool management can lead to an estimated 30% increase in operational costs. To combat this, implementing effective strategies can enhance tool longevity, thereby improving productivity.

One key tip for extending tool performance is to optimize cutting parameters. Adjusting feed rates and spindle speeds according to the specific material being machined can significantly reduce wear. For example, a study from the Manufacturing Technology Centre indicates that optimizing these parameters can increase tool life by as much as 25%. Additionally, incorporating effective cooling strategies, such as flood coolant or mist systems, can prevent overheating, which is a primary cause of tool failure.

Another vital strategy is to perform regular maintenance and inspections of milling equipment. Keeping machines in top condition ensures that tools are held securely and aligned properly, which minimizes unnecessary wear. Research from the American Society of Mechanical Engineers (ASME) shows that a routine maintenance schedule can extend tool life by up to 40%. By prioritizing these practices, manufacturers can maximize efficiency and maintain the precision necessary for competitive production.

10 Expert CNC Milling Tips for Maximizing Efficiency and Precision in Production

| Tip Number | CNC Milling Tip | Description | Expected Benefit |

|---|---|---|---|

| 1 | Optimize Cutting Speed | Adjust the spindle speed based on material type. | Improves surface finish and reduces tool wear. |

| 2 | Use the Correct Tool Material | Choose carbide or high-speed steel tools for durability. | Extends tool life and enhances overall efficiency. |

| 3 | Implement Tool Path Optimization | Plan the tool path to minimize unnecessary movements. | Reduces machining time and increases productivity. |

| 4 | Maintain a Clean Work Environment | Regularly clean the CNC machine and workspace. | Prevents contamination and ensures precision. |

| 5 | Use Proper Cutting Fluids | Select appropriate cutting fluids for cooling and lubrication. | Reduces heat buildup and tool wear. |

| 6 | Regular Tool Inspection | Inspect tools regularly for wear and tear. | Ensures optimal performance and prevents failure. |

| 7 | Train Operators Effectively | Provide comprehensive training for operators. | Enhances skills and reduces costly mistakes. |

| 8 | Monitor Machine Performance | Use data analytics to track machine efficiency. | Identifies areas for improvement and optimization. |

| 9 | Adjust File Feed Rates | Set correct feed rates suitable for the material. | Ensures smooth operation and precision cutting. |

| 10 | Implement Scheduled Maintenance | Create a proactive maintenance schedule for machines. | Minimizes downtime and extends machine service life. |

Optimizing Cutting Parameters: Balancing Speed, Feed, and Depth for Precision

Optimizing cutting parameters is crucial for achieving the best results in CNC milling, significantly impacting both efficiency and precision in production. Balancing speed, feed rate, and depth of cut is essential to ensure the material is machined effectively without compromising the quality of the finished product. The cutting speed, defined as the rate at which the tool engages the material, should be adjusted based on the workpiece material and the type of tool being used. Too high a speed can lead to excessive wear and overheating, while too low can reduce productivity.

Feed rate, the distance the tool moves into the material per revolution, must also be carefully calibrated. A higher feed rate can enhance production speed but may lead to a decrease in surface finish quality if not managed properly. Depth of cut influences the volume of material removed in each pass; an appropriate depth can enhance efficiency, but it should align with the machine's capabilities to prevent tool breakage and ensure consistent results. By precisely adjusting these parameters, manufacturers can achieve a harmonious balance that maximizes both efficiency and precision, ultimately leading to superior output in CNC milling processes.

The Importance of Fixture Design in Enhancing Stability and Accuracy

The design of fixtures plays a crucial role in CNC milling operations, significantly influencing both stability and accuracy in production. An effective fixture secures the workpiece firmly, minimizing vibrations and movement during the milling process. This stabilization is essential for maintaining dimensional tolerances and ensuring that the machined parts meet stringent specifications. By employing well-designed fixtures, manufacturers can reduce setup times and enhance repeatability, making it easier to achieve consistent results across multiple production runs.

Additionally, the fixture design should consider accessibility for tool changes and chip removal, which can further improve efficiency. Properly engineered fixtures can accommodate various workpiece geometries and simplify the clamping process, allowing for quick adjustments and swapping between different jobs. As a result, investing time and resources into designing robust fixtures not only enhances machining accuracy but also contributes to a more streamlined workflow, leading to higher overall productivity in CNC milling operations.

10 Expert CNC Milling Tips for Maximizing Efficiency and Precision in Production

This bar chart illustrates the impact score of various CNC milling tips on maximizing efficiency and precision during production. A higher score indicates a more significant positive effect on overall machining effectiveness.

Implementing Advanced Software Solutions for Improved CNC Workflow

The integration of advanced software solutions in CNC milling is crucial for enhancing workflow efficiency and precision in production. The global computer-aided manufacturing (CAM) market is projected to grow significantly, from USD 3.39 billion in 2024 to USD 5.69 billion by 2030. This growth is driven by the increasing adoption of sophisticated CAM tools that streamline operations, reduce lead times, and improve overall manufacturing accuracy.

Recent developments, such as the acquisition of a leading CNC software developer, highlight the industry's commitment to innovation and the pursuit of enhanced production capabilities. Such advancements enable manufacturers to implement AI-driven strategies that automate processes, thereby significantly transforming traditional machining practices. The emergence of 'no code' programming solutions further exemplifies the trend towards simplifying complex processes in metrology and CAD/CAM systems, ultimately fostering greater shop productivity. This emphasis on technology adoption signals a transformative shift in how CNC milling operations will be executed in the future, leading to improved productivity and competitive advantage.

Routine Maintenance and Calibration: Key Practices for Consistent Output

Routine maintenance and calibration are essential practices that ensure CNC milling machines operate at peak efficiency. Regularly scheduled maintenance helps prevent unexpected machine breakdowns, which can lead to costly downtime. Key tasks include checking the lubrication system, inspecting and tightening belts and drives, and cleaning chips and debris from the machine’s components. These actions not only prolong the lifespan of the equipment but also enhance the quality of the machined parts by reducing wear and maintaining optimal performance.

Calibration is another crucial aspect that directly affects precision in production. Over time, any CNC machine can drift from its original settings, resulting in inaccuracies. Regular calibration checks of the machine’s axes, tool offsets, and spindle speed are necessary to maintain tight tolerances and ensure that each part is manufactured to specifications.

Implementing a structured calibration schedule, along with detailed record-keeping, helps manufacturers quickly identify any deviations and rectify them before they impact production quality. By prioritizing routine maintenance and calibration, companies can achieve consistent output, minimize waste, and increase overall productivity.

Related Posts

-

How to Optimize CNC Milling Processes for Maximum Efficiency

-

The Future of CNC Milling Innovation Shaping Manufacturing Today

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Overcoming the Common Challenges in Sourcing the Best CNC Metal Milling Machines

-

Exploring the 2025 Tech Trends in CNC Metal Machining: Innovations Driving Industry Efficiency

-

Top Strategies for Enhancing Precision Machining Efficiency in Your Manufacturing Process

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.