Why Choose a CNC Milling Machine: Benefits and Applications Explained

In the ever-evolving landscape of manufacturing, the CNC milling machine stands out as a pivotal innovation that has transformed production processes across various industries. Expert engineer and CNC technology consultant, Dr. Emily Hart, emphasizes the machine's significance, stating, "The precision and versatility of CNC milling machines enable manufacturers to achieve levels of detail and efficiency previously unattainable." This statement underscores the invaluable role of CNC milling machines in enhancing operational capabilities.

The benefits of adopting a CNC milling machine extend beyond mere precision. They include improved workflow efficiency, reduced production time, and the ability to work with a vast array of materials ranging from metals to plastics. As industries transition towards more automated and precise manufacturing techniques, understanding the multifaceted applications and advantages of CNC milling machines has become crucial for companies looking to stay competitive.

Moreover, the adaptability of CNC milling technology allows it to cater to a wide range of applications, from prototyping to mass production. As businesses seek to optimize their manufacturing processes, recognizing the critical attributes of CNC milling machines and their practical applications is essential for leveraging their full potential in today’s market.

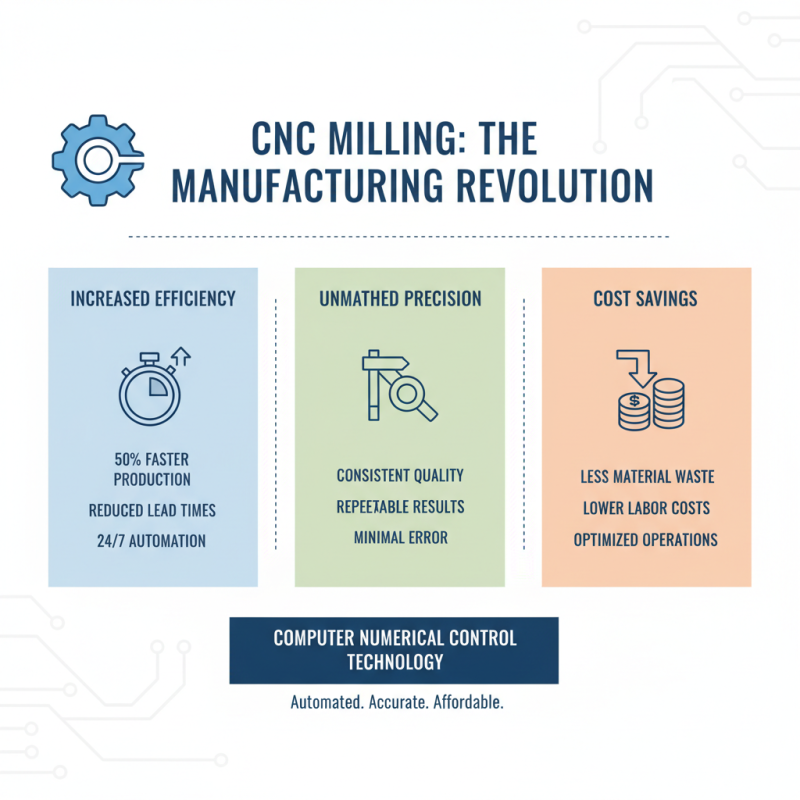

Benefits of CNC Milling Machines in Modern Manufacturing Processes

CNC milling machines have become an essential component in modern manufacturing processes due to their precision and versatility. One of the most significant benefits of these machines is their ability to produce intricate parts with a high degree of accuracy. The use of computer numerical control allows for consistent replication of designs, reducing the risk of human error and ensuring uniformity across production batches. This accuracy not only improves product quality but also enhances the efficiency of the manufacturing process by minimizing waste and the need for rework.

Another advantage of CNC milling is its adaptability to various materials. From metal to plastics, CNC milling machines can work with a wide range of substances, making them invaluable in diverse industries such as aerospace, automotive, and medical sectors. The ability to easily switch between different tasks and materials helps manufacturers respond swiftly to market demands and changing customer needs. Moreover, the automation of processes streamlines production workflows, allowing for higher output rates and reduced labor costs, ultimately contributing to a more profitable and sustainable manufacturing environment.

Key Applications of CNC Milling Machines Across Various Industries

CNC milling machines have become indispensable across a wide range of industries due to their precision and efficiency. In the manufacturing sector, CNC milling is extensively used for producing complex components with tight tolerances. Industries such as aerospace and automotive rely heavily on these machines for creating intricate parts like engine components, brackets, and housings that require high accuracy to ensure performance and safety. The ability to automate repetitive tasks not only increases production speed but also reduces the likelihood of human error, which is critical in high-stakes applications.

In addition to manufacturing, CNC milling finds significant use in the medical industry. Custom prosthetics and surgical instruments are manufactured using CNC technology to meet specific patient needs. The precise cutting and shaping capabilities enable the production of unique designs that are essential for both functionality and comfort. Furthermore, the electronics industry utilizes CNC milling to create finely detailed circuit boards and enclosures, allowing for the rapid prototyping of new devices. This versatility across different fields showcases the broad applicability of CNC milling machines, making them a cornerstone technology in modern manufacturing.

Efficiency and Precision: Data Supporting CNC Milling Advancements

CNC milling machines have revolutionized the manufacturing landscape by enhancing efficiency and precision in various applications. These machines utilize computer numerical control technology to automate the milling process, offering consistent, repeatable results that manual methods often struggle to achieve. Data indicates that CNC milling can increase production speed by up to 50% compared to traditional machining, significantly reducing lead times and operational costs.

Moreover, the precision offered by CNC milling is unparalleled, with the capability to achieve tolerances as tight as a few microns. This level of accuracy is crucial in industries such as aerospace, automotive, and medical device manufacturing, where even the slightest deviation can lead to catastrophic failures. The integration of advanced software and real-time monitoring allows for immediate adjustments during the machining process, further enhancing quality control. As industries continue to demand higher standards and faster turnaround times, CNC milling machines stand out as a vital tool for achieving these objectives effectively.

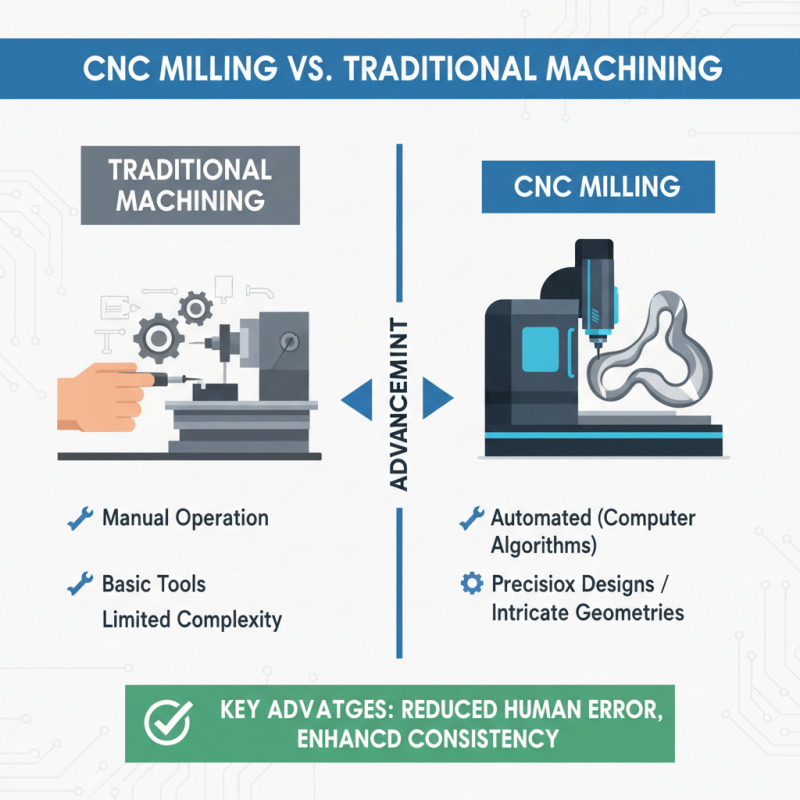

Comparative Analysis: CNC Milling vs. Traditional Machining Methods

CNC milling machines have gained significant traction over traditional machining methods due to their precision and versatility. One of the key advantages of CNC milling is automation, which drastically reduces human error and enhances the consistency of the manufactured components. Unlike traditional machining, which often relies heavily on manual operation and basic tools, CNC milling employs computer algorithms to dictate the milling process, allowing for complex designs and intricate geometries that would be difficult to achieve with conventional machining techniques.

Another notable difference lies in the efficiency and speed of operations. CNC milling machines can process materials at a much faster rate while maintaining high levels of accuracy. Traditional machining methods require multiple setups and adjustments, prolonging the production time. In contrast, CNC mills can be programmed to automate these adjustments, thereby streamlining the workflow. Additionally, the capability of CNC machines to work with a wide range of materials further establishes their superiority over traditional methods, as they can handle everything from soft metals to hard plastics without compromising quality. This adaptability makes CNC milling an ideal choice for various industries, including automotive, aerospace, and manufacturing, where precision and efficiency are paramount.

Trends in CNC Milling Technology: Innovations Shaping the Future

The landscape of CNC milling technology is rapidly evolving, driven by innovations that enhance precision, efficiency, and versatility. One significant trend is the integration of artificial intelligence and machine learning algorithms into CNC milling processes. These technologies enable machines to adapt to varying production parameters in real-time, leading to optimized cutting paths and reduced material waste. As CNC systems become more intelligent, they can also predict maintenance needs, minimizing downtime and improving overall productivity.

Another key development in the CNC milling sector is the rise of advanced materials and coatings that enhance tool durability and performance. New composite materials and specially engineered coatings provide better wear resistance and thermal stability, allowing milling machines to operate effectively under harsher conditions. Additionally, the incorporation of additive manufacturing techniques into CNC milling opens up the possibility of hybrid machining, where traditional subtractive methods coexist with additive processes, leading to complex geometries and improved part design capabilities.

Sustainability is also becoming a fundamental focus, with manufacturers exploring eco-friendly materials and energy-efficient practices. Techniques such as optimized energy consumption during milling, along with the use of recyclable materials, are not only reducing the carbon footprint of CNC operations but are also appealing to environmentally conscious consumers. As these trends continue to shape the future of CNC milling, the industry is set to embrace more intelligent, sustainable, and adaptive machining solutions.

Related Posts

-

Top Benefits of CNC Milling for Precision Manufacturing in Modern Industry

-

How to Optimize CNC Milling Processes for Maximum Efficiency

-

10 Expert CNC Milling Tips for Maximizing Efficiency and Precision in Production

-

The Future of CNC Milling Innovation Shaping Manufacturing Today

-

Overcoming the Common Challenges in Sourcing the Best CNC Metal Milling Machines

-

What is CNC Machine Fabrication and How Does It Work in Manufacturing

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.