Top Benefits of CNC Milling for Precision Manufacturing in Modern Industry

In recent years, the manufacturing industry has witnessed a significant transformation driven by technological advancements, and CNC milling has emerged as a pivotal process in precision manufacturing. According to a report by MarketsandMarkets, the CNC machine market is projected to grow from $59.9 billion in 2020 to $105.6 billion by 2025, indicating an annual growth rate of 11.3%. This growth underscores the increasing reliance on CNC milling technologies, which offer unparalleled precision and efficiency compared to traditional machining methods.

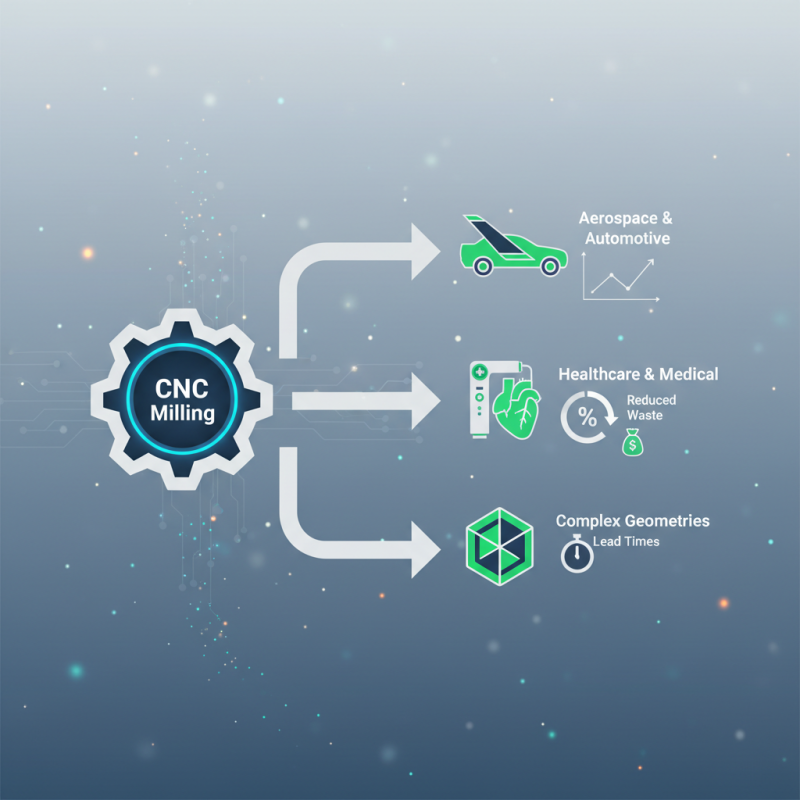

CNC milling, or Computer Numerical Control milling, has become integral to various sectors, including aerospace, automotive, and healthcare. The precision offered by CNC milling not only enhances product quality but also reduces material waste significantly. A study from the National Institute of Standards and Technology (NIST) revealed that CNC machining can help manufacturers reduce scrap rates by up to 30%, translating to substantial cost savings and improved resource management. Furthermore, the ability to produce complex geometries with high accuracy makes CNC milling an essential tool for modern manufacturers striving for innovation and competitiveness.

As industries continue to evolve and demand rises for high-quality components, the benefits of CNC milling—ranging from enhanced precision and reduced lead times to improved operational efficiency—will likely solidify its position as a cornerstone of precision manufacturing in the years to come. Embracing this technology not only enables manufacturers to meet the growing challenges of the market but also positions them for sustained success in an increasingly competitive landscape.

Overview of CNC Milling and Its Importance in Manufacturing

CNC (Computer Numerical Control) milling has revolutionized the precision manufacturing landscape by offering unparalleled accuracy and efficiency. It involves the use of computerized controls to operate machining tools, enabling manufacturers to produce complex components with tight tolerances. This technology is essential in modern industries such as aerospace, automotive, and medical devices, where precision is paramount. CNC milling machines can handle a variety of materials, allowing for the customization of parts while maintaining high quality.

The importance of CNC milling in manufacturing lies in its ability to significantly reduce production time and minimize human error. Traditional milling processes often rely heavily on manual intervention, which can lead to inconsistencies and longer lead times. In contrast, CNC milling automates these processes, thereby increasing productivity and ensuring repeatability in production. Furthermore, advanced CNC systems can incorporate intricate designs and changes on-the-fly, giving manufacturers the flexibility to adapt to market demands swiftly. This adaptability, combined with the ability to produce high-quality components efficiently, makes CNC milling an indispensable tool in today's competitive manufacturing environment.

Top Benefits of CNC Milling for Precision Manufacturing

Key Advantages of CNC Milling in Precision Production

CNC milling has become an indispensable component of precision manufacturing in modern industry, driven by its ability to produce highly accurate and complex parts. One of the key advantages of CNC milling is its consistency. According to a report by the International Journal of Advanced Manufacturing Technology, CNC machines can achieve tolerances as tight as ±0.005 inches, which significantly reduces the variance often seen in manual machining processes. This precision is particularly valuable in industries such as aerospace and automotive, where even the slightest misalignment can lead to catastrophic failures.

Another notable benefit of CNC milling is its efficiency in production. Studies indicate that CNC milling can reduce production time by up to 60% compared to traditional machining methods. This efficiency stems from the automated nature of CNC machining, which minimizes the need for human intervention and allows for longer continuous operation. In addition, the flexibility of CNC milling enables manufacturers to quickly adapt to design changes, significantly shortening lead times and enhancing responsiveness to market demands. With these advantages, it is clear that CNC milling plays a vital role in optimizing production processes across various sectors.

Enhanced Accuracy and Repeatability in Machining Processes

CNC milling has revolutionized precision manufacturing by significantly enhancing the accuracy and repeatability of machining processes. With advancements in technology, modern CNC milling machines can achieve tolerances as tight as ±0.002 inches, ensuring that each produced part meets stringent specifications. According to a report by the National Institute of Standards and Technology (NIST), companies utilizing CNC machining can experience a 30% reduction in production time while improving dimensional accuracy. This level of precision is crucial for industries such as aerospace and medical device manufacturing, where even the slightest deviation can have critical implications.

To optimize the accuracy in CNC milling, it's essential to regularly maintain and calibrate your machines. Keeping tools sharp and ensuring workpieces are securely clamped can significantly reduce variations in manufacturing. Additionally, utilizing advanced software for simulation and planning can help identify potential issues before the actual machining process begins, allowing for adjustments that safeguard precision.

Moreover, programming techniques, such as high-speed machining and adaptive control, further enhance repeatability in machining operations. By adapting tool paths and feed rates in real time based on feedback, CNC systems can maintain consistency in production. Implementing these strategies can lead to lower waste rates and higher quality products, making CNC milling a cornerstone technology in today's precision manufacturing landscape.

Cost Efficiency and Time Savings in CNC Milling Operations

CNC milling has become an essential process in precision manufacturing due to its exceptional cost efficiency and time-saving features. The automation of manufacturing tasks through CNC (Computer Numerical Control) technology allows for highly precise machining with minimal human intervention. This not only reduces labor costs but also diminishes the likelihood of errors that can arise from manual processes. By streamlining production lines, businesses can maximize their output while minimizing waste, ultimately leading to significant cost reductions.

In addition to lowering costs, CNC milling operations also enhance time efficiency. The capability of CNC machines to execute complex tasks with remarkable speed enables manufacturers to meet tight production deadlines effectively. Setup times are reduced since CNC milling requires fewer manual adjustments, allowing for quicker transitions between different jobs. Moreover, the durability of CNC equipment means longer operational lifespans and less time spent on maintenance, further contributing to overall time savings. By embracing CNC milling, industries can not only accelerate their manufacturing processes but also improve their competitive edge in an ever-evolving market.

Top Benefits of CNC Milling for Precision Manufacturing in Modern Industry

| Benefit | Description | Impact on Efficiency | Cost Savings |

|---|---|---|---|

| Precision | CNC milling provides high precision and repeatability, crucial for complex parts. | High | Reduces waste and rework costs |

| Automation | CNC milling machines can operate autonomously, reducing the need for manual labor. | Medium | Lowers labor costs |

| Flexibility | CNC milling can be easily programmed for different tasks, enhancing production flexibility. | High | Enables quicker adaptations to market demand |

| Reduced Lead Times | Automated processes speed up production, significantly reducing lead times. | Very High | Improves cash flow and customer satisfaction |

Applications of CNC Milling Across Various Industries

CNC milling technology has found its way into a multitude of industries, transforming the landscape of precision manufacturing. In the aerospace sector, CNC milling is essential for producing intricate components such as turbine blades and brackets, which require both high tolerances and lightweight characteristics. The ability to work with various materials, including metals and composites, allows for the creation of parts that meet rigorous safety and performance standards. As the aerospace industry continually strives for efficiency and innovation, CNC milling becomes a critical tool in meeting these demands.

In the automotive industry, CNC milling is employed to manufacture complex parts with utmost accuracy. Components like engine blocks, transmission cases, and chassis elements benefit from the high precision that CNC milling offers, enabling manufacturers to achieve better performance and reliability in their vehicles. Furthermore, the technology is also widely used in the production of custom prototypes, allowing automakers to expedite the development process while ensuring that designs are feasible and production-ready. Additionally, the medical industry leverages CNC milling for creating intricate surgical instruments and implants, which require precision and biocompatibility, underlining the versatility of this technology across various fields.

Related Posts

-

How to Optimize CNC Milling Processes for Maximum Efficiency

-

10 Expert CNC Milling Tips for Maximizing Efficiency and Precision in Production

-

The Future of CNC Milling Innovation Shaping Manufacturing Today

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

Overcoming the Common Challenges in Sourcing the Best CNC Metal Milling Machines

-

How to Select the Right CNC Metal Solutions for Your Global Manufacturing Needs

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.