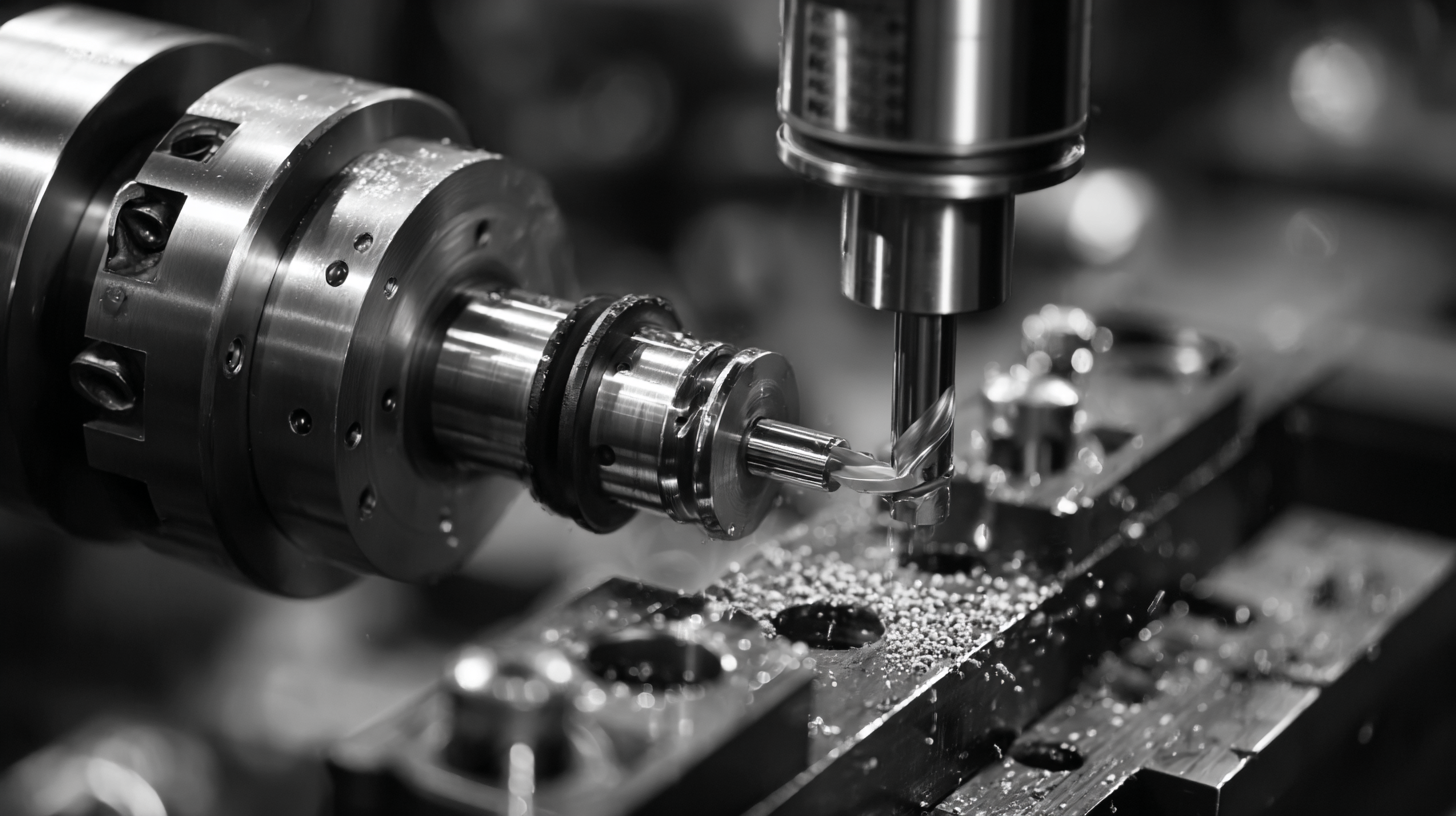

How to Choose the Right Machining Parts for Your Project Needs

Choosing the right machining parts for your project is a critical decision that can significantly impact the efficiency, quality, and cost-effectiveness of production. According to a recent market analysis by Industry Research, the global precision machining market is projected to reach $208 billion by 2025, with an annual growth rate of over 6%. This growth underscores the increasing importance of selecting appropriate machining components tailored to specific applications. In today's competitive landscape, understanding the properties, tolerances, and manufacturing processes of machining parts can help engineers and project managers make informed choices that meet performance standards while optimizing resources. Thus, knowing how to choose the right machining parts is not just beneficial; it is essential for achieving project success and maintaining competitiveness in the evolving manufacturing sector.

Understanding Material Properties and Their Impact on Machining Parts Selection

When selecting machining parts for your project, understanding the material properties is crucial. Different materials possess unique characteristics, such as tensile strength, hardness, and thermal resistance, which can significantly influence the performance and durability of the final product. For instance, metals like aluminum and steel are often chosen for their strength, while plastics may be selected for their lightweight and corrosion-resistant properties. Therefore, it’s essential to evaluate the specific requirements of your project against the qualities of available materials.

Tips: When in doubt, consult with material engineers or suppliers who can provide insights about how different materials will behave under various conditions. Additionally, consider running simulations or prototypes to assess the performance of your chosen material before full-scale production.

Another factor to consider is the machining process itself, as not all materials are compatible with every technique. Some materials are better suited for milling, while others may require turning or even additive manufacturing. Understanding the interplay between material properties and the machining process can prevent costly mistakes and delays.

Tips: Familiarize yourself with the limitations of your machining equipment and the properties of materials. This proactive approach will help you choose parts that not only align with your design specifications but also enhance manufacturability and reduce waste.

Evaluating Tolerances and Their Importance in Precision Engineering

When selecting machining parts for your project, evaluating tolerances is a crucial step in ensuring precision and optimal performance. Tolerances define the allowable variation in part dimensions and can significantly impact the functionality of a component. According to a report by the National Institute of Standards and Technology (NIST), even a mere 1% deviation in tolerances can result in a 10% decrease in product quality and performance. This emphasizes the importance of setting appropriate tolerance levels tailored to the specific requirements of your engineering project.

Furthermore, the critical nature of precision engineering calls for a thorough understanding of how tolerances affect assembly and interoperability of components. Research from the American Society of Mechanical Engineers (ASME) indicates that tighter tolerances, while often improving fit and function, can also increase manufacturing costs by about 20 to 40%. Therefore, it's essential to find a balance that meets performance demands without inflating production expenses unnecessarily. By assessing the specific tolerances required for each part based on functionality and application, engineers can make informed decisions that ensure both quality and cost-effectiveness in their projects.

Analyzing Cost-Effectiveness: Balancing Quality and Price for Machining Parts

When choosing machining parts for specific project requirements, one of the most critical factors to consider is cost-effectiveness. Balancing quality and price is essential to ensure that the parts not only meet performance standards but also fit within budget constraints. High-quality machining parts may come with a premium price tag, but they often provide better durability and precision, which can lead to savings in the long run by reducing the need for replacements or repairs.

On the other hand, opting for lower-cost alternatives might initially seem appealing, but it could compromise the overall project quality and lead to additional expenditures due to increased failure rates or inefficiencies. Therefore, it's vital to analyze the specific needs of your project and evaluate potential suppliers against criteria like material quality, manufacturing processes, and support services. By carefully considering both the upfront costs and the long-term implications of machining part choices, one can strike a balance that ensures optimal value while meeting project specifications.

Assessing Production Volume Needs: Custom vs. Standard Parts in Manufacturing

When embarking on a machining project, one critical factor to consider is the production volume. This often determines whether to opt for custom or standard parts. For low to medium production volumes, standard parts are usually the most efficient and cost-effective solution. These readily available components can streamline the manufacturing process, allowing for quicker turnaround times and reduced lead times. Industries often rely on these parts to meet tight deadlines without compromising quality.

In contrast, custom parts are essential for high-volume production or applications where specific specifications and tolerances must be met. When the standard options do not suffice due to unique project requirements, investing in custom machining can lead to better performance and integration into larger systems. Although custom parts typically involve higher upfront costs, they often result in enhanced efficiency, reduced waste, and the potential for long-term savings over the lifespan of the project. Choosing the right option ultimately hinges on a careful assessment of both production volume needs and the specific requirements of the project at hand.

Identifying Supplier Credentials: Importance of Certifications and Industry Experience

When embarking on a machining project, it’s crucial to assess potential suppliers thoroughly. The credentials of a supplier often reflect their capability to meet your specific needs. Certifications play a pivotal role in this evaluation; they demonstrate adherence to industry standards and quality control practices. Look for certifications such as ISO 9001, which indicates a commitment to maintaining quality management systems. This can assure you that the parts you receive will meet your specifications consistently.

Tip: Always verify the supplier's industry experience. Suppliers with extensive experience in your particular sector are more likely to understand the nuances and requirements of your project. Such expertise can also lead to valuable insights that could enhance the functionality of the parts and overall project efficiency.

Another aspect to consider is the supplier’s track record in delivering quality machining components. Ask for case studies or references from previous clients to gauge their performance and reliability. A supplier’s ability to provide examples of past successes can help you make an informed decision, ensuring that the machining parts you choose will not only fit your project requirements but also contribute positively to your project’s success.

Tip: Don’t hesitate to request samples or prototypes. This allows you to assess the quality of the machining parts firsthand before making a significant investment.

Choosing the Right Machining Parts: Supplier Credentials

This chart illustrates the importance of various supplier credentials when selecting machining parts for projects, focusing on certifications and industry experience.

Related Posts

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Navigating the Future: 2025 Market Insights for Best Precision Machining with Essential Strategies Revealed

-

Top Strategies for Enhancing Precision Machining Efficiency in Your Manufacturing Process

-

How to Reduce Maintenance Costs with Exceptional After Sales Service for the Best CNC Steel

-

How to Select the Right CNC Metal Solutions for Your Global Manufacturing Needs

-

10 Essential Tips for Optimizing CNC Machine Working Efficiency in Your Factory

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.