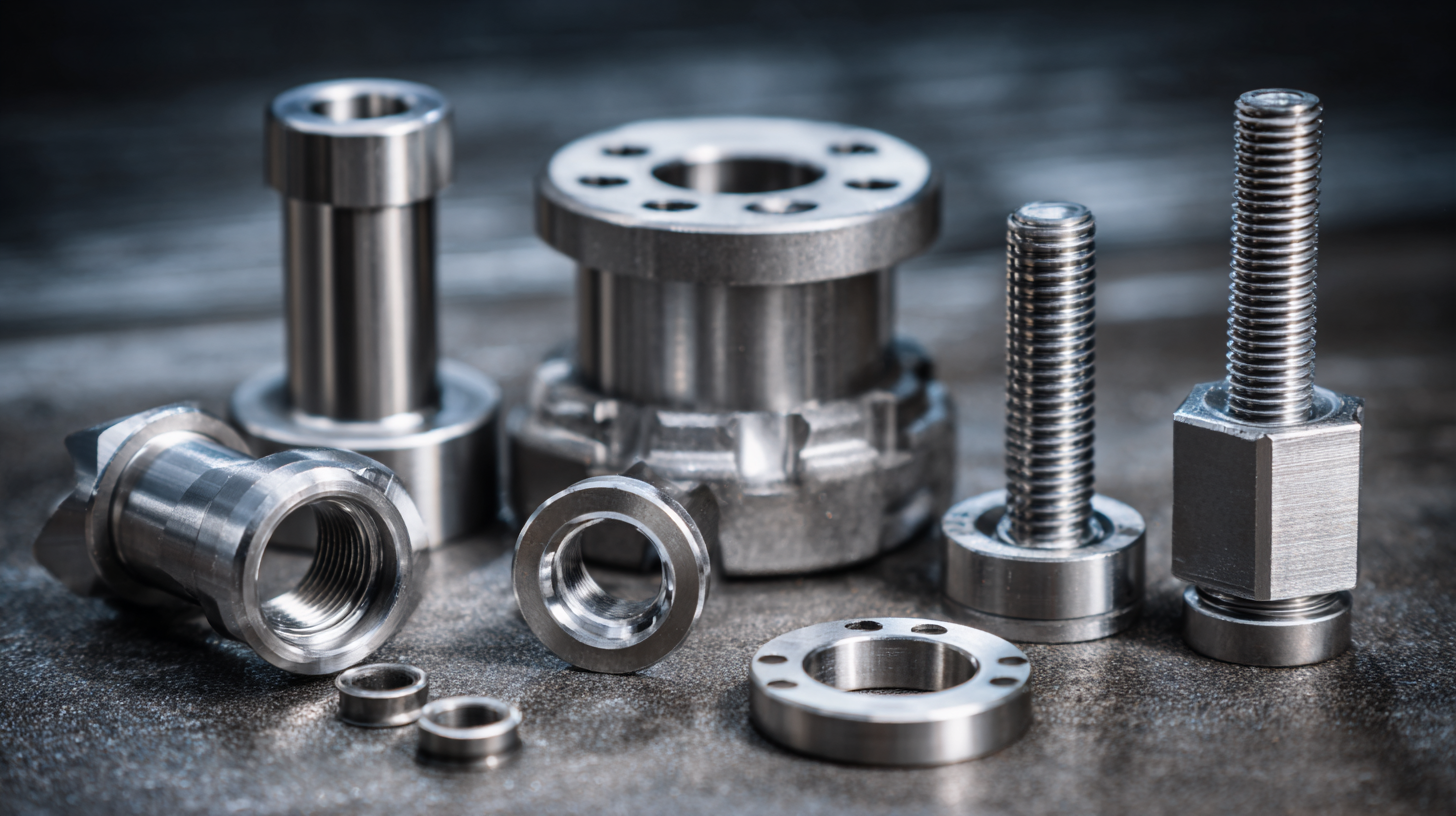

How to Choose the Right CNC Parts for Your Next Project

When embarking on a new project, the choice of CNC parts is crucial for ensuring precision, efficiency, and overall success. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.2 billion by 2026, with the demand for high-quality CNC parts driving innovation and quality standards across industries. Selecting the right components not only improves the performance of your CNC machines but also extends their lifespan and reduces maintenance costs. With advancements in materials and technology, today’s CNC parts offer enhanced durability and adaptability, making it essential for engineers and manufacturers to stay informed about the latest trends and specifications. Proper selection of CNC parts can ultimately lead to higher productivity and better end products, making it a vital consideration for any project.

Understanding Project Requirements for CNC Parts Selection

When selecting CNC parts for your project, understanding your project requirements is crucial. Begin by clearly defining the specifications of your project, including the desired dimensions, tolerances, and materials. Knowing whether you need precision machining for intricate designs or durability for heavy-duty applications will guide you in choosing the appropriate parts. Different projects may also demand specific mechanical properties; for instance, lightweight materials might be necessary for aerospace applications, while sturdier options are better suited for automotive uses.

In addition to material and specifications, consider the intended functionality of the CNC parts. Analyze the end-use environment, as certain parts may require enhanced resistance to heat, chemicals, or wear and tear. Furthermore, project timelines and budget constraints can significantly influence parts selection. Opting for readily available components may expedite the process, while custom parts could offer tailored benefits at a potentially higher cost. Balancing these factors will ensure that your CNC parts not only meet but exceed your project expectations.

Key Factors to Consider When Choosing CNC Components

When selecting CNC parts for your next project, several key factors must be meticulously evaluated to ensure optimal performance and efficiency. First and foremost, material compatibility plays a crucial role. According to a report by the American Society of Mechanical Engineers (ASME), the right combination of materials can enhance the durability and life span of CNC components by up to 30%. For instance, choosing aluminum for lightweight applications or steel for heavy-load operations can vastly influence the success of the final product.

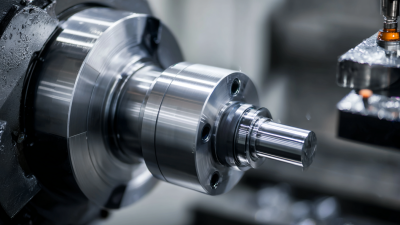

Another important consideration is precision and tolerances. A study from the International Journal of Advanced Manufacturing Technology indicates that utilizing high-precision components can improve the overall accuracy of CNC operations by 25% or more. Components such as linear guides, ball screws, and spindles must be selected based on their precision ratings to reduce errors and enhance the quality of machined parts. Therefore, understanding the specifics of tolerances and the intended application will guide you in making informed decisions that lead to superior outcomes in your CNC projects.

Material Selection Guide: Finding the Best Fit for Your CNC Parts

When selecting materials for CNC parts, it’s crucial to consider the intended application and performance requirements of your project. Different materials offer varying properties such as strength, weight, and corrosion resistance. For instance, aluminum is a popular choice for its lightweight characteristics and good machinability, making it suitable for applications in aerospace and automotive industries. On the other hand, steel provides superior strength and durability, ideal for heavy-duty components but at the cost of increased weight.

Additionally, consider the environment in which the CNC parts will operate. If the parts will be exposed to harsh chemicals or extreme temperatures, selecting a material that can withstand these conditions, such as stainless steel or special polymers, is essential. Furthermore, don’t overlook the impact of cost and availability of the material. It’s important to find a balance between material performance and budget constraints, ensuring that the selected materials not only meet the functional requirements but also align with your overall project goals.

Balancing Quality and Cost in CNC Component Choices

When selecting CNC parts for your next project, it’s crucial to find the right balance between

quality and cost. High-quality components often guarantee better precision,

durability, and performance, which can significantly influence the overall outcome of your project. Investing in superior

materials and manufacturing processes can lead to fewer defects and reworks, ultimately saving time and money in the long run.

However, the key is to assess which components are essential for quality performance and which can be cost-effective without

compromising the project’s integrity.

On the other hand, prioritizing cost savings might seem appealing, especially for budget-conscious projects. However, opting

for cheaper parts can result in higher failure rates and subpar results, leading to additional costs over time.

Therefore, conducting thorough research on suppliers and understanding the specifications of the components is essential.

Consider factors like warranties, customer reviews, and material certifications to make informed decisions that meet both

budget constraints and quality standards. By carefully analyzing the right components, you can ensure the success of your

project while balancing financial considerations with the necessities of quality performance.

Top Brands and Suppliers for Reliable CNC Parts in Your Project

When it comes to selecting the right CNC parts for your project, the choice of brands and suppliers plays a crucial role in ensuring reliability and performance. Top brands known for their quality CNC components include Haas Automation, Fanuc, and Siemens. These manufacturers have established a reputation for producing durable and precise parts that can enhance the efficiency of your CNC machines. Their products are often backed by extensive research and development, ensuring that you receive cutting-edge technology designed to meet high industrial standards.

In addition to these major players, there are numerous suppliers that offer high-quality CNC parts tailored to specific needs. Companies like McMaster-Carr and Grainger provide a wide variety of CNC components, making it easier for you to find exactly what you need. Local suppliers may also offer personalized service and quicker delivery times, which can be beneficial for urgent projects. Researching these options and reading customer reviews will help you identify reliable sources that match your project's specifications and budget constraints.

Comparison of CNC Parts by Type

Related Posts

-

The Future of Precision Engineering: Innovations in Best CNC Parts Production

-

How to Select the Right CNC Metal Solutions for Your Global Manufacturing Needs

-

7 Key Factors That Elevate Your Success in Best Precision Machining Today

-

10 Essential Tips for Optimizing CNC Machine Working Efficiency in Your Factory

-

Ultimate Guide to Large Part CNC Machining: Insights and Trends in Precision Manufacturing

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.