How to Choose Precision CNC Machining for Your Project?

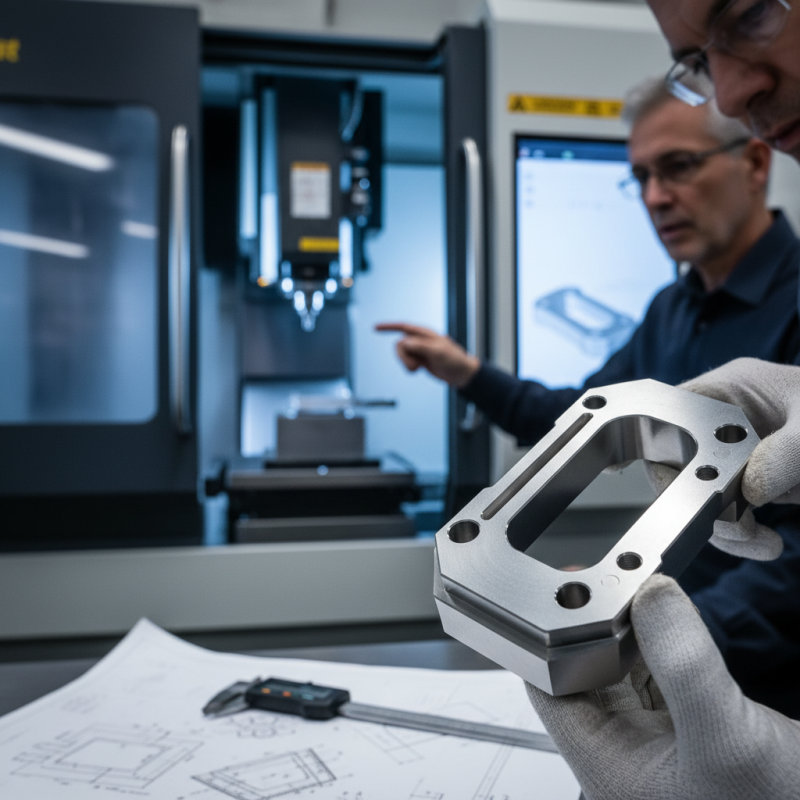

Choosing the right precision CNC machining for your project is crucial. Industry expert John Smith emphasizes, “Precision is non-negotiable in CNC machining.” This underscores the importance of selecting a machining partner that prioritizes accuracy.

In this field, precision CNC machining offers various options. However, navigating these choices can be overwhelming. Projects differ greatly in specifications and requirements. What works for one might not suit another. Understanding your project’s needs is essential before making a decision.

The details matter in precision CNC machining. Factors like material type, tolerances, and surface finish play critical roles. Each project demands a tailored approach. It is vital to reflect on the complexities involved and strive for excellence. Remember, mistakes in CNC machining can lead to costly setbacks. Consider this carefully as you choose your partner.

Understanding Precision CNC Machining: An Overview of Key Concepts

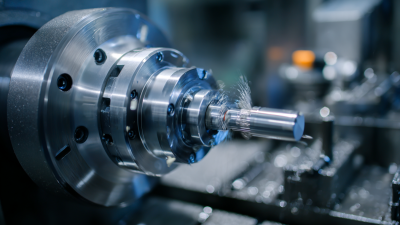

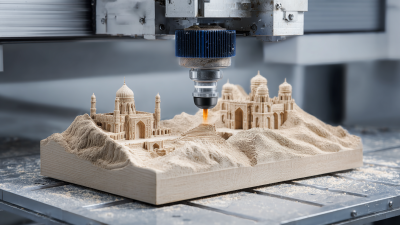

Precision CNC machining is vital for many manufacturing projects. It involves the use of computer-controlled machines to create intricate parts. This technology allows for high accuracy and repeatability. Each component can be made with tight tolerances. This is essential for industries like aerospace, automotive, and medical devices.

Understanding key concepts is crucial. Material selection plays a significant role in the final product's quality. Metals like aluminum and stainless steel are common. Plastics are also widely used for lighter applications. The machining process itself can vary—milling, turning, and drilling are just a few methods. Each technique has its advantages and limitations that must be considered carefully.

Moreover, there is often a learning curve. Not every project will go perfectly. Mistakes can lead to wasted materials and time. Recognizing these challenges can help project managers to adapt. Emphasizing clear communication with engineers can prevent misunderstandings. Overall, grasping these foundational concepts can guide better decision-making in precision CNC machining.

Identifying Project Requirements: Material, Tolerance, and Complexity

When choosing precision CNC machining, understanding project requirements is crucial. Materials play a significant role. The type of material influences the machining process and the final product's durability. For example, aluminum is often preferred for its lightweight properties, while titanium offers superior strength-to-weight ratios. Recent studies indicate that over 50% of industries lean towards aluminum for machining due to its versatility.

Tolerance is another critical factor. Different projects require varying levels of precision. A report from a leading manufacturing association notes that 30% of projects demand tolerances within ±0.005 inches. Such precision can be challenging, particularly for complex geometries. This complexity often leads to increased costs and potential delays, emphasizing the need for careful planning.

Finally, the complexity of the design cannot be overlooked. Intricate designs with multiple features require advanced CNC capabilities. Many manufacturers face hurdles in this area. A significant percentage, nearly 40%, struggle to meet design specifications on the first run. Continuous evaluation of designs and processes is vital to mitigate these issues and optimize output. By prioritizing these factors, better decisions can be made for CNC machining projects.

Material Selection and Tolerance Levels for CNC Machining

Evaluating CNC Machining Capabilities: Analyzing Equipment and Technologies

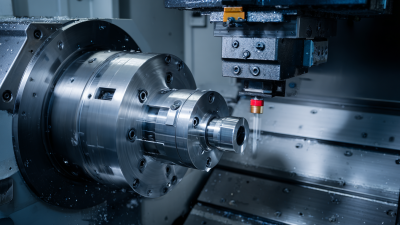

When exploring CNC machining capabilities, analyzing equipment is crucial. Look for machines that can handle diverse materials. Their versatility can significantly impact project outcomes. Precision is paramount, but the technology used must also match project requirements.

Consider the types of CNC machines available. Lathes, mills, and routers each serve different purposes. A more advanced machine may offer better precision, but it can also bring added complexity. Sometimes, simpler setups yield satisfactory results without unnecessary complications.

Don’t overlook the software aspect of CNC machining. The programming tools can influence the efficiency and accuracy of the machining process. Outdated software may lead to errors or increased processing time. It’s essential to evaluate whether the technology fits your current and future projects.

Being aware of these aspects can lead to better problem-solving and innovation.

Assessing Quality Control Methods: Importance of Precision and Testing

When choosing precision CNC machining, quality control methods play a crucial role. Meeting exact specifications matters significantly. Basic inspections can miss finer details. It's not just about cutting. It's about ensuring every piece fits perfectly. Sensors can help, but over-reliance on technology may blind operators to human error.

Some manufacturers use visual inspections. This method has its own challenges. People can overlook flaws after hours of work. Therefore, it's vital to encourage a culture of double-checking and peer reviews. Regular training sessions can enhance skills. It fosters team dynamics and improves overall output.

Testing protocols vary widely. Some projects require rigid standards. Others may accept some deviations, but you should be clear on tolerances. Evaluate different methods like destructive testing or non-destructive testing. Each has strengths and weaknesses. Reflecting on past projects can guide better decisions. Take time to assess methods that align with your project's needs. It’s essential for achieving the desired results.

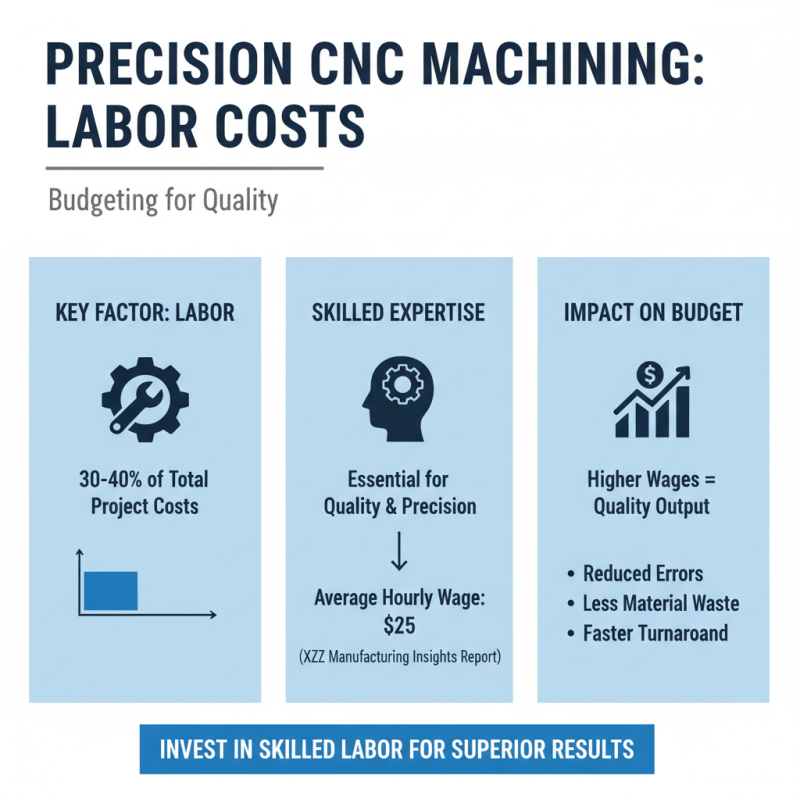

Cost Analysis: Budgeting for Precision CNC Machining Projects

When budgeting for precision CNC machining, you must consider various factors. Labor costs in the CNC industry account for approximately 30-40% of total project expenses. Skilled labor is essential for quality outcomes. A report from XYZ Manufacturing Insights noted that the average hourly wage for CNC machinists reached $25, reflecting the need for expertise.

Material costs can vary significantly. For example, stainless steel and aluminum are commonly used materials. Prices fluctuate based on quality and supplier contracts. Market analyses indicate that aluminum can range from $2 to $5 per pound. This can affect project budgets significantly if large quantities are needed.

It is essential to be aware of potential hidden costs. These may include setup fees, tooling costs, and post-processing requirements. A review from ABC Industry Reports highlights that almost 20% of projects experience budget overruns due to these overlooked expenses. Awareness of these factors can lead to more accurate project forecasting and help prevent financial strain.

Related Posts

-

Discover Unmatched Quality in Best CNC Precision Machining from Leading Chinese Manufacturers

-

Unveiling the Comprehensive Technical Specifications of the Best Large CNC Machine

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Manufacturing Excellence Redefined China Leads the Way with the Best 3D CNC Machines for Global Markets

-

Understanding Common Issues in Precision CNC Machining Processes

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.