How to Choose the Best 3D CNC Machine for Your Projects in 2023

Choosing the right 3D CNC machine for your projects in 2023 can be a daunting task due to the myriad of options available in the market. As the demand for precision manufacturing and intricate designs continues to rise, understanding the essential features and capabilities of these machines becomes crucial. Whether you are a seasoned professional or a hobbyist, selecting a 3D CNC machine that aligns with your specific needs can significantly enhance your productivity and the quality of your outputs.

In this guide, we will explore key considerations to help you navigate the selection process. From analyzing your project requirements to evaluating machine specifications, we will provide insights that will assist you in making an informed decision. With advancements in technology, newer models offer enhanced features such as higher accuracy, improved material compatibility, and user-friendly interfaces, making it essential to stay updated on what to look for when investing in a 3D CNC machine. By understanding these factors, you will be better equipped to choose the perfect machine that will elevate your project outcomes and driving innovation in your work.

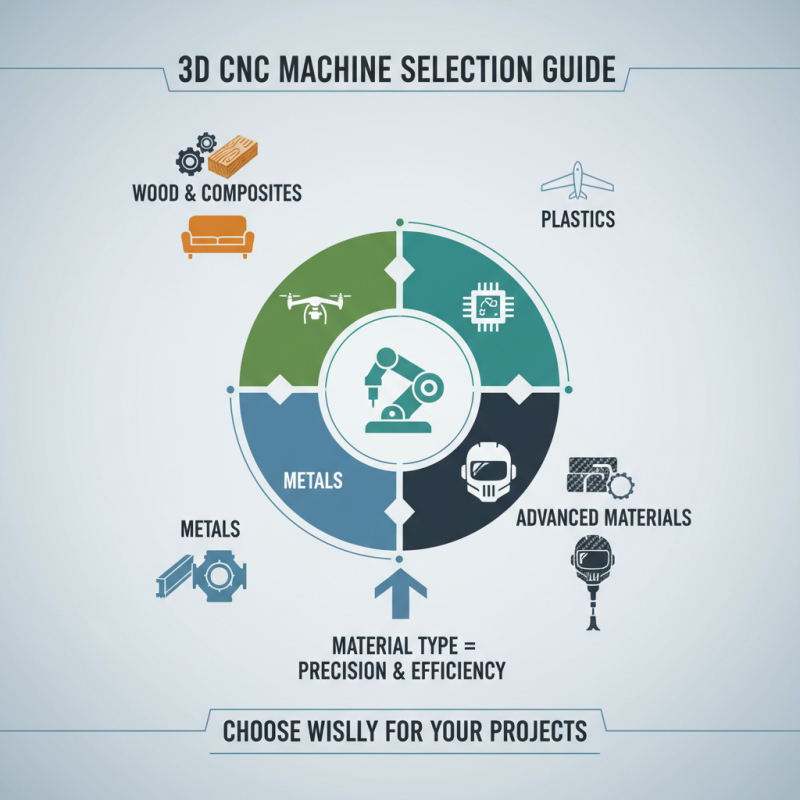

Factors to Consider When Selecting a 3D CNC Machine

When selecting a 3D CNC machine for your projects, several factors need careful consideration to ensure the right fit for your specific needs. One of the primary aspects is the type of materials you intend to work with. Different CNC machines are designed to handle various materials such as plastics, wood, metal, or composites. It's crucial to choose a machine that accommodates the material requirements of your projects to achieve the desired precision and efficiency.

Another essential factor is the machine's build volume, which refers to the maximum size of the objects you can create. Depending on your project requirements, you may need a larger or more compact machine. Additionally, consider the machine’s capabilities, such as the number of axes it operates on, which influences the complexity of the designs you can produce. Look for machines that offer features like variable speed control and precision tools, as these attributes can significantly enhance the quality of the finished product. Lastly, evaluating software compatibility and user interface is vital to ensure a smooth workflow from design to production.

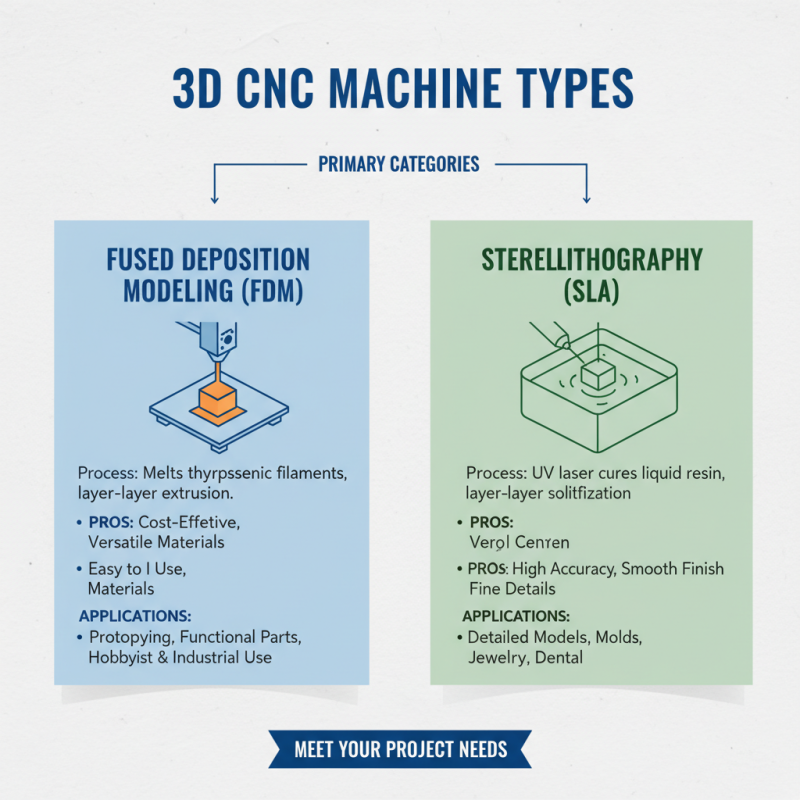

Types of 3D CNC Machines and Their Applications

When selecting a 3D CNC machine, it's crucial to understand the various types available and their specific applications to effectively meet your project needs. The two primary categories of 3D CNC machines are fused deposition modeling (FDM) and stereolithography (SLA). FDM machines work by melting thermoplastic filaments and extruding them layer by layer to create parts. This type is highly favored for prototyping and producing functional parts due to its cost-effectiveness and ease of use. FDM machines are excellent for a range of applications, from hobbyist projects to industrial prototypes, offering versatility in material choices.

On the other hand, SLA machines utilize a laser to cure liquid resin into hardened plastic. This method produces highly detailed and smooth surface finishes, making SLA machines ideal for applications that demand precision, such as jewelry design, dental models, and intricate prototypes. Additionally, CNC milling machines, which are not exclusively 3D but can remove material from a solid block, are often employed for precision machining in metal and woodwork. Each type of 3D CNC machine carries distinct advantages and is suited for specific tasks; making an informed decision will enable you to enhance productivity and achieve optimal results for your projects.

Key Specifications to Evaluate in 3D CNC Machines

When selecting the best 3D CNC machine for your projects in 2023, there are several key specifications to consider that can significantly impact performance and project outcomes. First and foremost, consider the machine's build volume, which pertains to the maximum size of the object that can be machined. According to industry reports, a larger build volume can allow for greater versatility in projects but may also increase the machine's footprint and price. For most hobbyists and small businesses, a build volume of 300 x 300 x 300 mm is often sufficient, while industrial applications may benefit from machines with volumes exceeding 1,000 mm.

Another crucial specification is the spindle speed and power of the machine. Higher spindle speeds, typically ranging from 12,000 to 60,000 RPM, enable the machine to cut through various materials more effectively, leading to a cleaner finish and faster production times. Additionally, the power rating measured in watts determines the machine's capability to handle harder materials like metals. Reports indicate that machines with at least 1.5 kW of power are generally reliable for a wider range of applications, from woodworking to metalworking, making them a more favorable option for demanding projects.

Lastly, consider the control system and precision of the CNC machine. A machine equipped with advanced motion control systems facilitates higher accuracy and repeatability. Industry data suggests that machines with a positioning accuracy of 0.01 mm or better are ideal for intricate designs and detailed work. Furthermore, the ease of use of the control software can impact productivity—selecting a machine with user-friendly software could save significant time during setup and operation, enhancing overall efficiency in your workflow.

Budgeting for Your 3D CNC Machine Purchase

When budgeting for your 3D CNC machine purchase, it’s essential to start by identifying your specific project needs. Consider the type of materials you’ll be working with, as this can significantly influence the machine's capabilities and, subsequently, its cost. A basic CNC machine may suffice for softer materials like wood and plastics, but if you plan to work with metals or more complex projects, you might need to invest in a more advanced model.

In addition to the initial purchase price, keep in mind the long-term costs associated with owning a CNC machine. This includes maintenance, software, tools, and additional accessories that may be necessary for your projects. It's wise to set aside a portion of your budget for unexpected expenses that could arise during operation. By thoroughly evaluating both your immediate and future expenses, you can make a more informed decision and ensure that your investment aligns with your project's goals and financial capabilities.

How to Choose the Best 3D CNC Machine for Your Projects in 2023 - Budgeting for Your 3D CNC Machine Purchase

| Feature | Entry-Level Machine | Mid-Range Machine | Professional Machine |

|---|---|---|---|

| Price Range | $500 - $1,500 | $1,500 - $5,000 | $5,000 and above |

| Max Cutting Area | 12" x 12" x 3" | 24" x 24" x 6" | 48" x 48" x 10" |

| Spindle Power | 300W | 800W | 2000W |

| Material Compatibility | Wood, Soft Plastics | Wood, Plastics, Metals | Wood, Plastics, Metals, Composites |

| Software Compatibility | Basic CAD/CAM | Advanced CAD/CAM | Professional CAD/CAM |

| Typical Applications | Hobby Projects | Prototyping, Small-Scale Production | Industrial Manufacturing |

Top Brands and Models of 3D CNC Machines for 2023

When considering the best 3D CNC machines of 2023, it's essential to focus on a few key brands and models that have garnered positive feedback for their performance, versatility, and reliability. One standout option features robust build quality and high precision, making it ideal for both hobbyists and professionals. This model often includes advanced software compatibility, enabling users to execute complex designs with ease, an essential factor for intricate projects.

Another notable contender is recognized for its user-friendly interface and excellent customer support. This model typically incorporates a variety of features such as adaptive control technology, which allows for adjustments based on material type and thickness, enhancing accuracy and reducing material waste. Overall, these machines are designed to cater to a wide range of applications, from woodworking and metalworking to prototyping and artistic endeavors, ensuring that users can find a solution that meets their specific project requirements in 2023.

3D CNC Machine Performance Comparison in 2023

Related Posts

-

Understanding CNC Machine Working Principles and Their Applications

-

Choosing the Right Manufacturer for Best CNC Machine Fabrication Solutions You Can Trust

-

Innovative Solutions for Your Home CNC Machine Investment

-

Top Benefits of CNC Milling for Precision Manufacturing in Modern Industry

-

Exploring Machining Parts Opportunities at the 138th Canton Fair 2025: Industry Insights and Trends

-

What is CNC Machine Fabrication and How Does It Work in Manufacturing

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.