Unmatched Quality in a Compact Package: The Best Small CNC Milling Machine from Trusted Chinese Manufacturers

As the demand for precision manufacturing continues to rise, the importance of selecting the right machinery cannot be understated. Recent industry reports indicate that the global CNC milling machine market is expected to reach USD 100 billion by 2027, with small CNC milling machines playing a pivotal role in this growth. These compact machines offer unparalleled versatility and precision, making them ideal for small businesses and hobbyists alike. Trusted Chinese manufacturers have emerged as key players in this sector, providing high-quality, cost-effective solutions without compromising on technology or performance. As we explore the top contenders in the market, it becomes clear that investing in a small CNC milling machine is not just a smart choice for efficiency but also a significant step towards competitive excellence in modern manufacturing environments.

As the demand for precision manufacturing continues to rise, the importance of selecting the right machinery cannot be understated. Recent industry reports indicate that the global CNC milling machine market is expected to reach USD 100 billion by 2027, with small CNC milling machines playing a pivotal role in this growth. These compact machines offer unparalleled versatility and precision, making them ideal for small businesses and hobbyists alike. Trusted Chinese manufacturers have emerged as key players in this sector, providing high-quality, cost-effective solutions without compromising on technology or performance. As we explore the top contenders in the market, it becomes clear that investing in a small CNC milling machine is not just a smart choice for efficiency but also a significant step towards competitive excellence in modern manufacturing environments.

The Rise of Chinese Manufacturing: A Analysis of Industry Leadership in CNC Milling

The rise of Chinese manufacturing in the CNC milling industry has been nothing short of remarkable. According to a recent report by the China National Machine Tool Corporation, Chinese CNC machine tool production has increased by over 25% annually over the past five years, establishing China as the world's largest manufacturer of CNC machines. This significant growth is fueled by advancements in technology, cost-effective production, and a commitment to quality, all of which make Chinese manufacturers a trusted choice for consumers seeking compact CNC milling machines.

**Tip:** When selecting a CNC milling machine, consider the manufacturer's technological capabilities. Look for companies that invest in research and development, as this often correlates with superior product quality and innovation.

Moreover, the competitive pricing of these machines allows small businesses and hobbyists to access high-quality equipment without breaking the bank. The Global Industry Analysts, Inc. projects that the CNC milling machine market will surpass $100 billion by 2025, with a substantial share attributed to Chinese exports. This trend highlights not only the efficiency of Chinese production but also the increasing global reliance on their manufacturing prowess.

**Tip:** Always verify certifications and customer reviews when purchasing CNC milling machines. Trusted manufacturers will have certifications that meet international standards, ensuring both safety and quality in their products.

Market Share of Small CNC Milling Machines (2023)

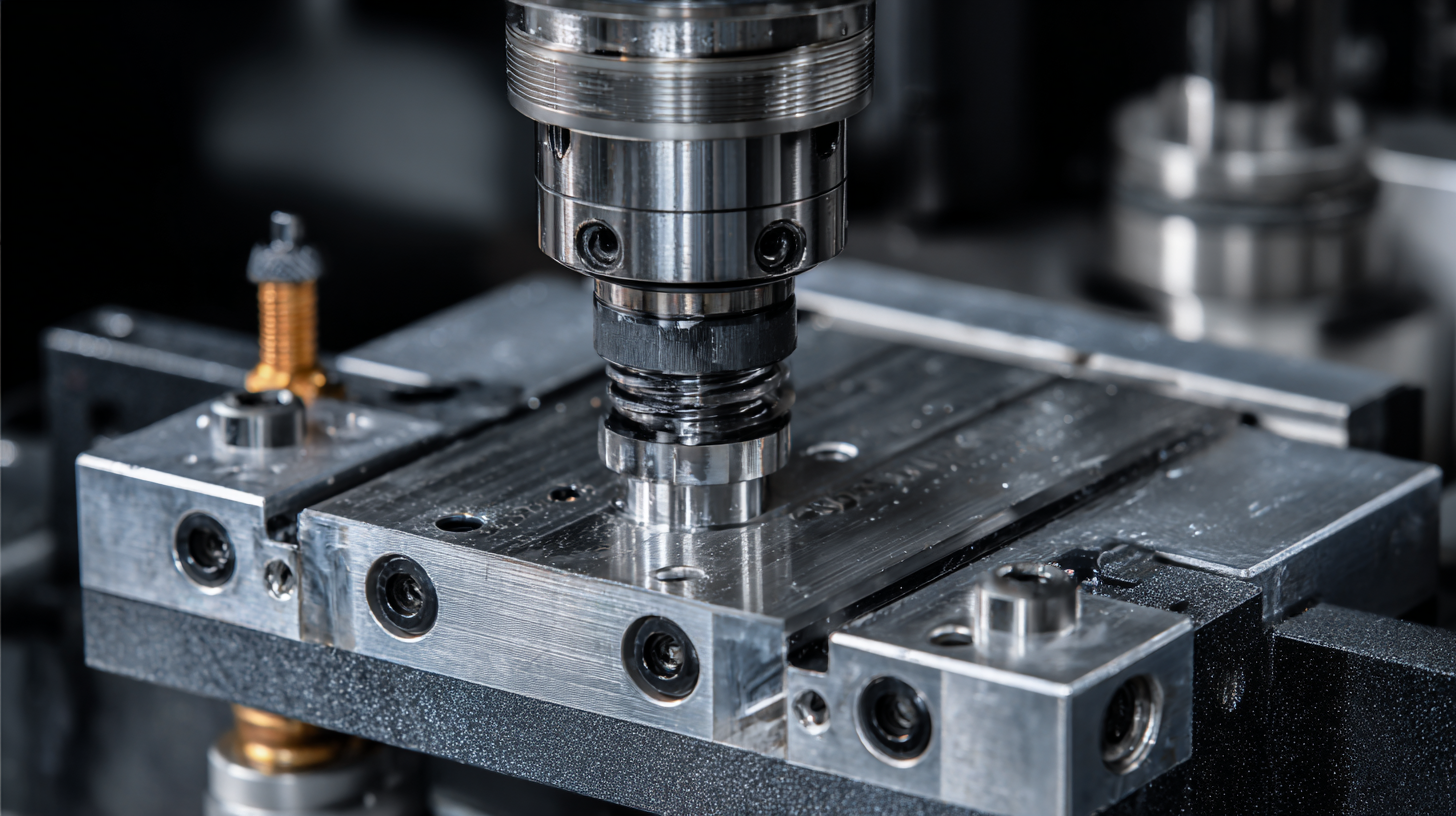

Key Features to Look for in a Compact CNC Milling Machine

When selecting a compact CNC milling machine, several key features should be prioritized to ensure unparalleled quality. One of the most critical aspects is the machine's construction material. According to a report by Grand View Research, the CNC machine market is projected to reach $100 billion by 2025, emphasizing the need for sturdy and reliable materials that enhance durability and precision. Machines made from high-grade cast iron or aluminum alloy not only provide a solid base for milling operations but also contribute to improved vibration dampening, which is essential for achieving fine tolerances.

Another essential feature to consider is the machine's axis configuration and movement capabilities. Most compact CNC milling machines on the market today offer at least three axes, but models with additional rotational axes can significantly expand operational versatility. The International Federation of Robotics indicates that the adoption of multi-axis systems can increase efficiency by up to 30%, allowing for more complex machining tasks without the need for additional setups. Furthermore, a user-friendly interface and advanced software compatibility can streamline operations, making these small machines ideal for both hobbyists and professional environments.

Unmatched Quality in a Compact Package: The Best Small CNC Milling Machine

| Key Features | Specification |

|---|---|

| Compact Size | 500mm x 500mm x 500mm |

| Maximum Spindle Speed | 12000 RPM |

| Working Table Size | 600mm x 400mm |

| Tool Storage Capacity | 10 tools |

| Control System | CNC G-code Compatible |

| Weight | 350 kg |

| Power Consumption | 1.5 kW |

| Precision | ±0.01 mm |

Comparing Performance: Top Small CNC Milling Machines from Trusted Chinese Brands

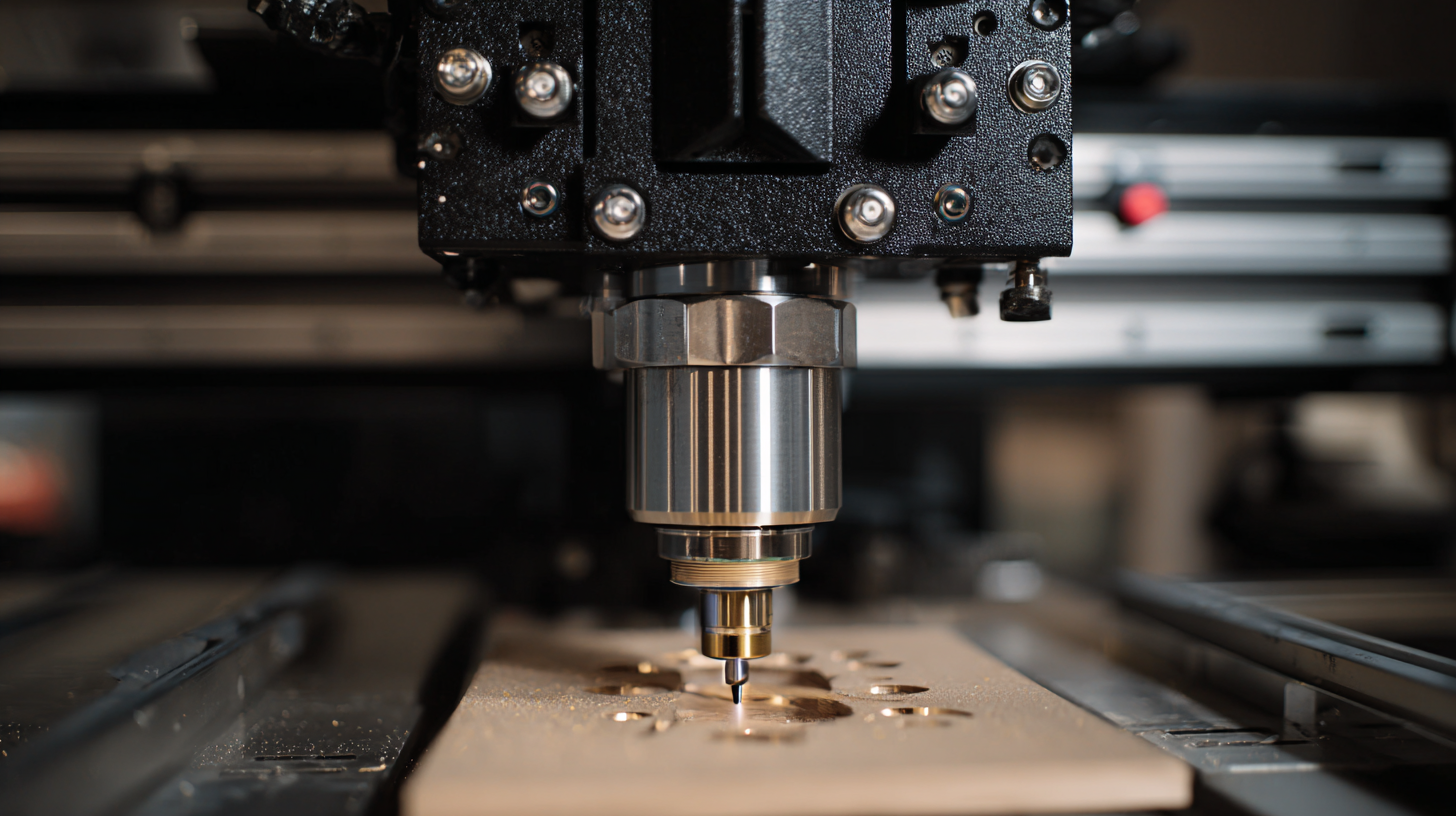

The advancement of small CNC milling machines has revolutionized manufacturing, offering precision and efficiency in a compact design. According to a report by MarketsandMarkets, the CNC machine market is expected to reach USD 100 billion by 2025, with small CNC machines accounting for a significant share due to their versatility and cost-effectiveness. Numerous trusted Chinese brands have emerged, providing a variety of high-quality products tailored for both small and mid-sized enterprises. For instance, machines from brands like HAAS Automation and Tormach are known for their robust performance and reliability, making them ideal choices for hobbyists and professionals alike.

When comparing the top small CNC milling machines from these trusted manufacturers, factors such as spindle power, precision, and software capabilities become crucial. For example, the SYIL X5 series is recognized for its exceptional accuracy, achieving tolerances of ±0.01 mm, which is supported by the industry standard of providing repeatability within ±0.005 mm. Additionally, many models now come equipped with user-friendly interfaces and advanced CAD/CAM software integration, streamlining the operation process and minimizing the learning curve. As demand for compact yet powerful machinery continues to rise, these machines are set to play a pivotal role in the future of automated manufacturing.

Cost-Effectiveness and Efficiency: Why Small CNC Machines Make Sense for Businesses

In recent years, small CNC milling machines have gained remarkable traction among businesses looking to optimize their operations without compromising on quality. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2025, with a significant share attributed to small CNC models due to their versatility and accessibility for small to medium-sized enterprises. These compact machines offer enhanced precision and speed, making them ideal for producing intricate components while maintaining tight tolerances, which is essential in industries such as aerospace and medical devices.

Cost-effectiveness further solidifies the appeal of small CNC milling machines. Research from IBISWorld indicates that companies investing in CNC technology can see productivity improvements of up to 30%, allowing them to realize a quicker return on investment. The acquisition cost of small CNC machines is generally lower compared to their larger counterparts, often starting below $10,000. This lower entry barrier enables businesses to embrace CNC technology without a hefty upfront investment, ultimately driving innovation and efficiency in their production processes. As manufacturers continue to enhance these technologies, small CNC machines stand out as a practical solution for businesses aiming to stay competitive in the evolving market landscape.

Customer Testimonials: Real-World Experiences with Chinese Small CNC Milling Solutions

When considering small CNC milling machines, customer testimonials play a crucial role in understanding real-world performance and reliability. According to a recent report by MarketsandMarkets, the CNC machine market is projected to grow at a CAGR of 6.5% from 2021 to 2026, driven by the demand for high-precision and efficient machining capabilities. Many users have echoed this sentiment, noting that trusted Chinese manufacturers are at the forefront of this innovation, offering compact machines without compromising on quality.

Real-world experiences shared by customers highlight the effectiveness of small CNC milling solutions in various applications. A user from a small automotive parts manufacturing company remarked, "Since investing in a Chinese small CNC milling machine, our production efficiency has improved by nearly 30%, allowing us to take on more projects." This is further supported by a survey from the International Federation of Robotics, which indicates that efficient manufacturing processes can lead to a 20% reduction in overhead costs. As more users recognize the value delivered by these machines, the demand for reliable, high-performance CNC solutions from trusted Chinese manufacturers continues to rise.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.