The Best 10 CNC Precision Machining Techniques You Should Know?

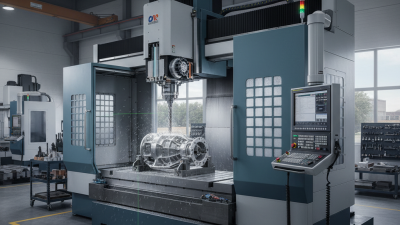

CNC precision machining is a vital process in modern manufacturing. It allows for high accuracy in creating complex parts. Many industries rely on these techniques to produce precise components. However, not all techniques are equally effective. Understanding the best machining methods is essential for engineers and technicians.

There are various CNC precision machining techniques. Each has its own strengths and weaknesses. For example, some methods excel in speed, while others focus on intricate details. It’s crucial to select the right technique based on the project's needs. Mistakes in this choice can lead to poor-quality products, wasting time and resources.

In this exploration, we will delve into ten essential CNC precision machining techniques. Each technique will be evaluated for its pros and cons. This knowledge could improve your manufacturing processes. With the right approach, you can enhance efficiency and quality in your projects.

Understanding CNC Precision Machining: An Overview of Techniques

CNC precision machining has revolutionized the manufacturing industry. It employs computer-controlled tools to create complex parts from metal, plastic, and other materials. The precision of these machines allows for high accuracy and repeatability, essential for any industry. Techniques such as turning, milling, and grinding are widely used, each with its specific applications.

Tips: Pay attention to the machine's settings. Small adjustments can lead to significant differences in output quality. Regular maintenance is crucial. It can prevent costly errors and downtime.

Understanding these techniques involves recognizing their strengths and weaknesses. For instance, milling is excellent for flat surfaces, but may struggle with intricate designs. Learning how to balance these factors is vital for effective production. Remember that experience plays a crucial role in honing your skills. Every setup can reveal new challenges and opportunities for improvement. Embrace mistakes as they can lead to valuable lessons.

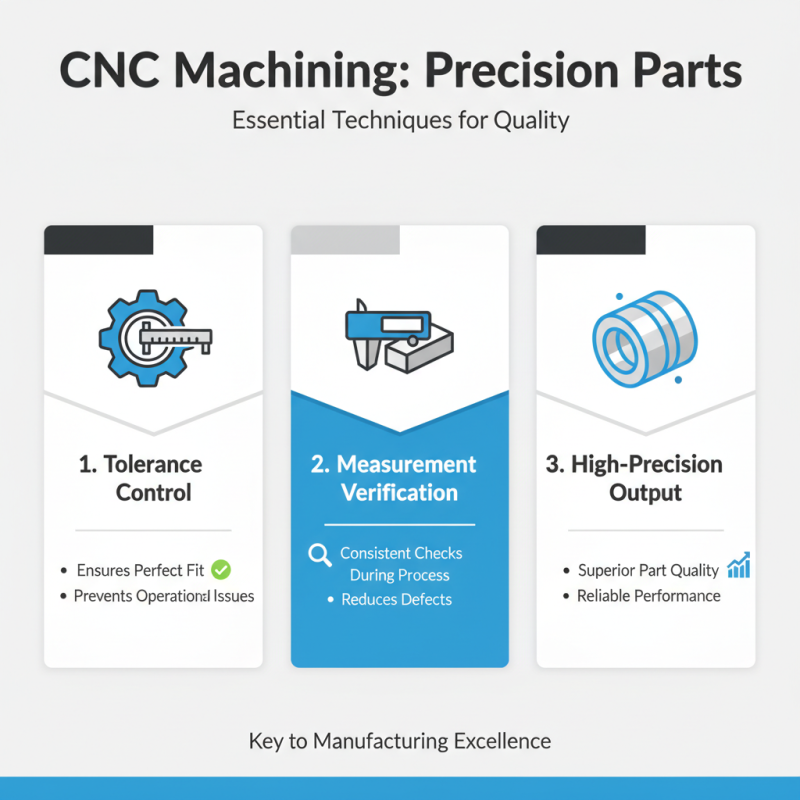

Essential CNC Machining Techniques for High Precision Parts Manufacturing

CNC machining is crucial for producing high precision parts. Understanding essential techniques can enhance manufacturing quality. One vital technique is tolerance control. It ensures parts fit together perfectly. Inconsistent tolerances can lead to operational issues. Always verify measurements during the process.

Another key technique is tool selection. Choosing the right tool affects surface finish. A dull tool may create rough edges, leading to functionality problems. It’s important to inspect tools regularly. Also, adaptive machining allows for real-time adjustments. This adaptability can fine-tune production for complex designs.

Lastly, programming skills matter greatly. Poorly written code can create defects in parts. Lengthy codes can lead to errors, causing delays. Regular training on software is essential for operators. Continuous learning helps maintain precision and efficiency. By focusing on these techniques, manufacturers can achieve greater accuracy and reliability in CNC machining.

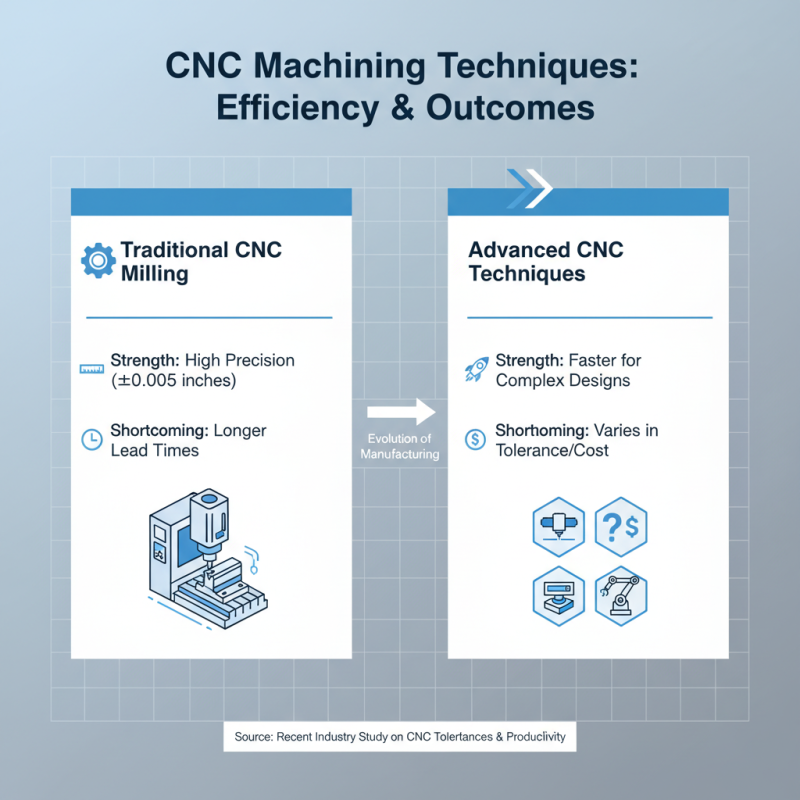

Comparative Analysis of CNC Machining Methods: Pros and Cons

CNC machining techniques vary in efficiency and outcomes. Each method has its strengths but also shortcomings. For example, traditional CNC milling is precise but may require more time for complex designs. A recent study reported that CNC milling can achieve tolerances of up to ±0.005 inches. However, this precision often comes at the cost of longer lead times, affecting productivity for fast-paced industries.

On the other hand, CNC turning is advantageous for cylindrical parts. It typically offers higher speed and can produce parts with better surface finishes. Data from industry reports show a 30% reduction in cycle times compared to milling in specific applications. Yet, it may struggle with intricate geometries. There’s a saying in the industry: "Fast is not always best." Balancing speed and precision is crucial. Additionally, additive manufacturing, although not a CNC technique, is gaining traction. It offers rapid prototyping but sometimes compromises on material strength.

In conclusion, each CNC method presents opportunities and challenges. Understanding these nuances can lead to smarter decisions in manufacturing processes. Be cautious of relying solely on one technique. Diversification may yield better results in the long run.

Advanced CNC Machining Techniques for Complex Geometries

When it comes to CNC precision machining, advanced techniques are vital for creating complex geometries. These methods allow manufacturers to produce parts with intricate shapes and tight tolerances. For example, multi-axis machining enables tools to move along multiple planes. This flexibility helps in crafting components that traditional machining cannot achieve.

Incorporating advanced software can also enhance precision. CAD/CAM integration simplifies the design process. However, not all designs translate well into reality. Some might face manufacturing challenges. Tool wear and material limitations can hinder the outcome. Adequate testing and adjustments are crucial.

Additionally, techniques like additive manufacturing complement CNC operations. They bring together subtractive and additive processes. This combination can lead to innovative designs and efficiency gains. Still, navigating these complexities requires careful consideration. Mistakes in design or execution can have significant repercussions. Reflecting on past challenges helps in honing these skills. Continuous learning is essential in this evolving field.

The Best 10 CNC Precision Machining Techniques You Should Know

| Technique | Description | Ideal Applications | Advantages |

|---|---|---|---|

| 5-Axis Machining | Allows for complex shapes and angles by moving the cutting tool along five axes. | Aerospace parts, intricate molds, and automotive components. | Increased precision and reduced production time. |

| CNC Turning | Rotates the workpiece against a stationary cutting tool to produce cylindrical parts. | Shafts, pins, and bushings. | High accuracy and fast machining times. |

| Laser Cutting | Uses focused laser beams to cut through materials. | Sheet metal, plastics, and wood. | Precision cutting with minimal material waste. |

| Waterjet Cutting | Employs high-pressure water to cut materials. | Metal, glass, and stone. | No heat-affected zone, preserving material integrity. |

| EDM (Electrical Discharge Machining) | Uses electrical discharges to erode material from a workpiece. | Injection molds, die casting, and tool manufacturing. | Ideal for hard metals and complex shapes. |

| Milling | Uses rotating cutters to remove material from a stationary workpiece. | Heavy parts, aerospace structures, and tooling. | Versatile and capable of high precision. |

| CNC Routing | Similar to milling, but primarily used for softer materials like wood and plastic. | Furniture, signage, and decorative items. | Cost-effective for large cuts and designs. |

| Cylindrical Grinding | Grinds the outer surface of cylindrical workpieces. | Precision parts and automotive components. | High precision and finish quality. |

| Multitasking Machines | Integrate multiple machining operations in one setup. | Complex assemblies and high production volumes. | Efficiency and reduced setup times. |

| Additive Manufacturing (3D Printing) | Builds parts layer by layer from materials. | Prototyping and custom parts. | Flexibility in design and reduced material waste. |

Emerging Trends in CNC Precision Machining Technology and Applications

CNC precision machining is evolving rapidly. New technologies and techniques are reshaping the landscape. Automation and artificial intelligence are at the forefront of these changes. They streamline operations and enhance production efficiency. This leads to improved accuracy and reduced waste in manufacturing processes.

Advanced materials are gaining traction. They often require specific machining methods. For instance, composites demand precision techniques to prevent delamination. The need for speed in production is also driving innovation. Companies are exploring new cutting speeds and feeds. However, balancing speed and quality remains a challenge. It's easy to overlook the importance of quality assurance amidst automation.

Another emerging trend is additive manufacturing integration. This combination of CNC machining and 3D printing is intriguing. It allows for the creation of complex geometries. However, it's not without its issues. There’s a steep learning curve for operators. Training and adapting are essential for success. As the industry progresses, staying updated with these trends is crucial. Each innovation brings both opportunities and obstacles to overcome.

The Best 10 CNC Precision Machining Techniques You Should Know

This bar chart represents the effectiveness of different CNC precision machining techniques based on industry surveys highlighting their usage rates and efficiencies.

Related Posts

-

Choosing the Right Manufacturer: A Comprehensive Comparison for the Best CNC Metal Products

-

How to Select the Right CNC Metal Solutions for Your Global Manufacturing Needs

-

What is CNC Machine Fabrication and How Does It Work in Manufacturing

-

10 Best Large CNC Machines for Precision Engineering in 2023

-

How to Overcome Common Challenges in Sourcing the Best CNC Precision Machining Solutions

-

Unlocking Precision: The Advantages of CNC Metal Machining in Modern Manufacturing

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.