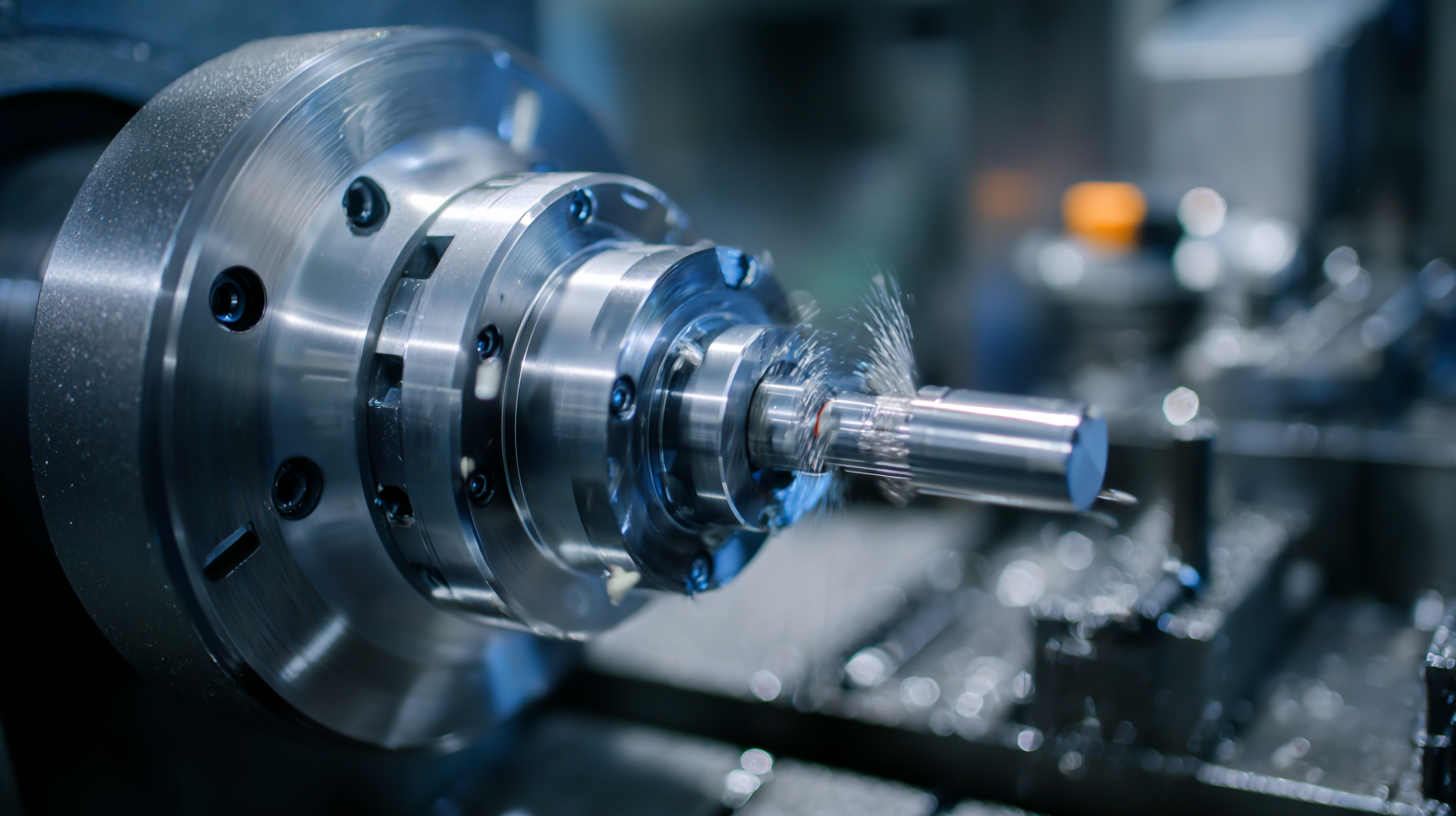

Discover Unmatched Quality in Best CNC Precision Machining from Leading Chinese Manufacturers

In today’s manufacturing landscape, the pursuit of unmatched quality in CNC precision machining is more critical than ever. As industries evolve, companies are increasingly relying on advanced technologies and skilled manufacturers to meet stringent quality standards.

Leading Chinese manufacturers have risen to prominence for their ability to deliver precision-engineered components that cater to diverse applications. However, navigating the complexities associated with CNC precision machining can also present several challenges, including:

Leading Chinese manufacturers have risen to prominence for their ability to deliver precision-engineered components that cater to diverse applications. However, navigating the complexities associated with CNC precision machining can also present several challenges, including:

- Quality control issues

- Material selection

- Production costs

Unveiling the Excellence of CNC Precision Machining in China

CNC precision machining in China stands as a hallmark of excellence, merging advanced technology with skilled craftsmanship. As the demand for high-quality precision components consistently rises across various industries, Chinese manufacturers have positioned themselves at the forefront of this sector. Employing cutting-edge equipment and techniques, they ensure that every piece meets stringent specifications and quality standards. This commitment to excellence is reflected in the precision and accuracy of their machined parts, which are essential in fields ranging from aerospace to automotive.

In addition to technological advancements, the robust supply chain and competitive pricing found in China enhance the appeal of CNC precision machining. Leading manufacturers leverage their extensive experience to refine production processes, resulting in faster turnaround times without compromising quality. The collaborative spirit within the industry fosters innovation, allowing companies to rapidly adapt to evolving market demands. By choosing Chinese manufacturers for CNC precision machining, businesses gain access to unparalleled quality and efficiency, positioning themselves well in the global marketplace.

Understanding the Global Impact of Chinese CNC Manufacturers

Chinese CNC manufacturers have increasingly established themselves as powerhouses in the global manufacturing landscape. According to a report from Mordor Intelligence, China accounted for over 30% of the global CNC machine tool market in 2022, showcasing the significant role these manufacturers play in meeting the rising demand for precision machining. The rapid advancements in technology and automation in China have allowed local companies to produce high-quality, cost-effective machining solutions that compete on a global scale.

Moreover, the global impact of Chinese CNC manufacturers is underscored by their export growth. The International Trade Administration notes that CNC machinery exports have consistently risen, with a reported compound annual growth rate (CAGR) of 6% from 2017 to 2022. This growth not only reinforces China’s position as a leading exporter of CNC machines but also reflects the confidence global industries place in Chinese manufacturing. By prioritizing innovation and efficiency, Chinese CNC manufacturers are not only transforming their domestic market but also driving a shift in global manufacturing capabilities, enabling businesses worldwide to enhance their production processes and improve product quality.

Key Industries Benefiting from High-Quality CNC Machining Services

As industries continue to evolve, the demand for high-quality CNC precision machining services has surged. Leading Chinese manufacturers have emerged as key players, providing innovative solutions that cater to various sectors including automotive, aerospace, electronics, and medical equipment. These industries greatly benefit from CNC machining due to its ability to produce complex parts with incredible accuracy and consistency, ensuring optimal performance and reliability.

One notable advantage of collaborating with top CNC machining providers is their commitment to quality control. By implementing rigorous testing and inspection processes, manufacturers can guarantee that each component meets stringent industry standards. Additionally, leveraging advanced technologies like automated machinery and computer-aided design (CAD) enables the production of highly efficient and precise components.

Tip: When selecting a CNC machining partner, consider their experience in your specific industry, along with their certifications and manufacturing capabilities. This will ensure you receive the best quality parts tailored to your needs.

Another key factor is the importance of clear communication throughout the design and production phases. Engaging early with manufacturers helps in identifying potential challenges and streamlining processes, leading to quicker turnaround times and improved product outcomes.

Tip: Always share detailed specifications and use 3D modeling tools to visualize and refine your designs before production begins, ensuring higher accuracy and reducing the chances of costly revisions.

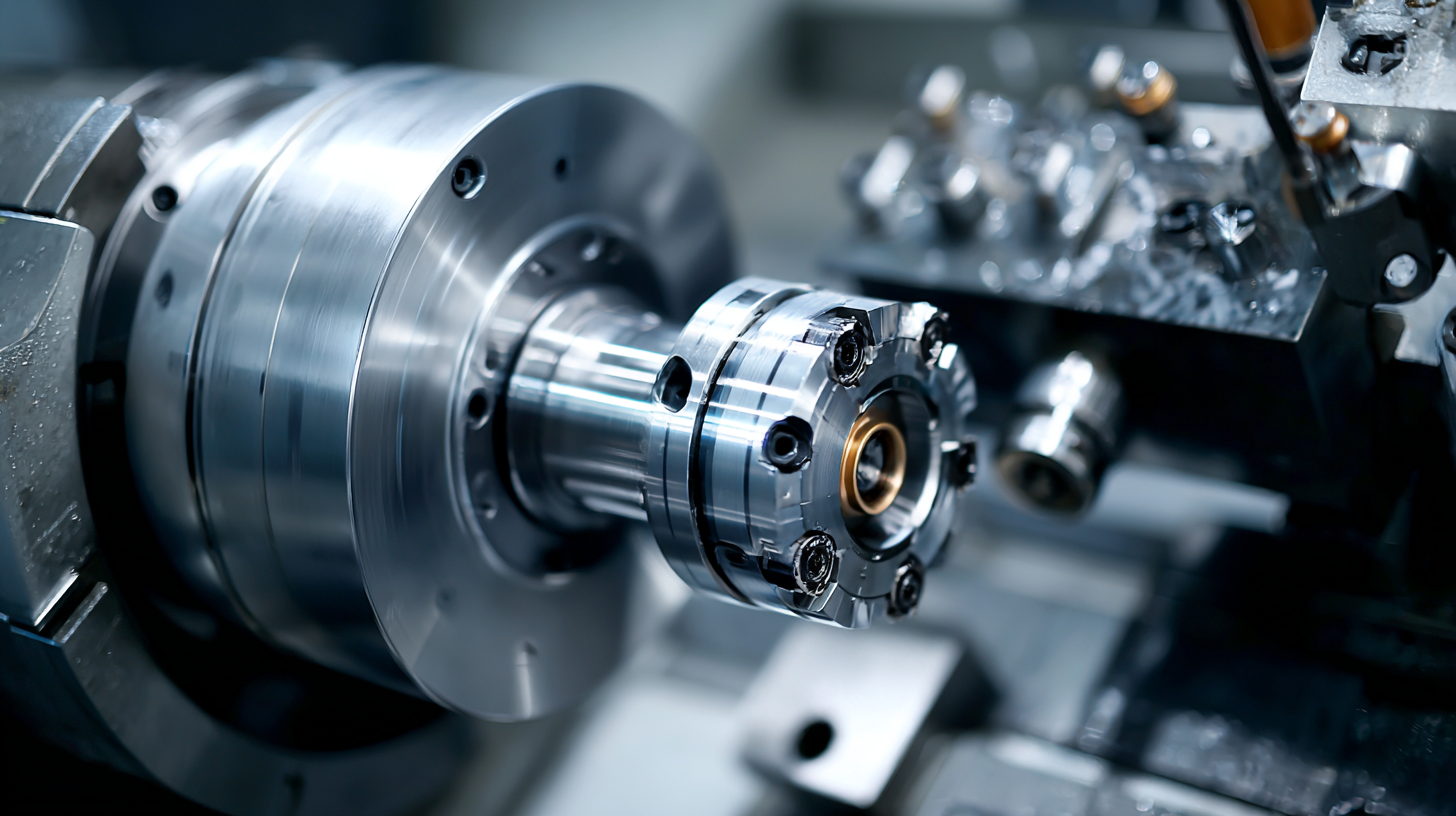

Innovative Technologies Driving CNC Precision in Chinese Factories

As the CNC (Computer Numerical Control) machine market continues to evolve, innovative technologies are at the forefront of driving precision in Chinese factories. The increasing adoption of digital manufacturing technologies has significantly enhanced productivity across a diverse range of industries, with the global CNC machine market projected to reach substantial heights by 2032. Reports indicate that the precision turned product manufacturing market alone is set to grow from approximately USD 108.79 billion in 2024 to an estimated USD 196.11 billion by 2034, highlighting the expanding influence of CNC technology.

Moreover, China is positioning itself as a leader in the machine tool industry, which serves as the backbone of manufacturing. With initiatives like the ambitious five-year metrology plan, China aims to redefine manufacturing excellence by treating metrology not merely as a compliance measurement but as a competitive differentiator. This approach reflects the commitment to disruptive innovation and the utilization of state-of-the-art technologies, propelling Chinese manufacturers to the forefront of the global market.

Furthermore, with rising automation demands influencing the precision coil winding machine market, opportunities for foreign businesses and investors in China’s machine tool sector are more significant than ever. Such developments showcase China’s strategic focus on enhancing its capabilities in CNC precision machining and sustaining growth amidst global competition.

Discover Unmatched Quality in Best CNC Precision Machining

| Metric | Value | Description |

|---|---|---|

| Material Types | Aluminum, Steel, Titanium | Common materials used in CNC machining. |

| Precision Tolerance | ±0.01 mm | Standard precision tolerance for CNC machining processes. |

| Production Capacity | Up to 5000 parts/month | The maximum number of parts that can be produced per month. |

| Lead Time | 2-4 weeks | Typical duration from order to delivery. |

| Technology Used | 3, 4, and 5-axis CNC Machines | Types of CNC machines utilized for precision machining. |

| Surface Finish | Ra 0.8 - Ra 1.6 µm | The range of surface roughness achievable. |

| Quality Certifications | ISO 9001, TS16949 | Certifications indicating commitment to quality management. |

Quality Control Practices Ensuring Superior CNC Machined Products

In today's competitive manufacturing landscape, quality control practices play a pivotal role in ensuring superior CNC machined products. Leading Chinese manufacturers are setting the standard by implementing rigorous quality control measures throughout the production process. According to a report by MarketsandMarkets, the global CNC machining market is expected to reach $100 billion by 2025, emphasizing the importance of adhering to high-quality standards to capture market share.

One critical aspect of quality control is the use of advanced measuring technologies. Manufacturers utilize Coordinate Measuring Machines (CMM) and laser scanning technologies to verify precision and accuracy in real-time. Studies show that manufacturers who regularly integrate such technologies improve their defect rates by up to 30%. This reduction not only enhances product quality but also boosts customer satisfaction and loyalty.

**Tip:** Always ensure that your chosen CNC manufacturer invests in high-quality inspection equipment.

Additionally, implementing a Total Quality Management (TQM) approach is vital. A TQM study revealed that companies adopting these practices witnessed a 25% increase in efficiency and a significant reduction in waste. By fostering a culture of quality among employees and encouraging continuous improvement, manufacturers can achieve unmatched quality in their CNC machined products.

**Tip:** Regular training and development programs for employees can enhance quality consciousness on the shop floor.

Let's Build Together

Contact Us: Call 435-563-3503

-OR- Fill in the form below and we will call you back.